Symmetric rolling forming method of large inner-step ring parts

A technology of symmetrical rolling and inner steps, used in metal rolling and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

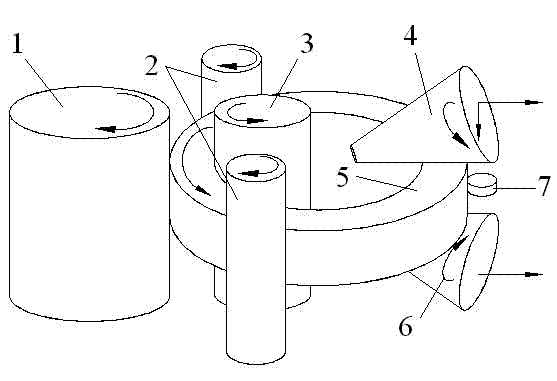

[0059] see Figure 1 to Figure 8 , the geometric dimension of ring 5 is: outer radius 784mm, inner radius 662mm, width 155mm, wall thickness at the largest inner diameter 65mm, step height 102mm, cutting allowance is 5mm. The radial and axial rolling forming process is realized in the following steps:

[0060] 1) Billet making: uniformly heat the bar section from room temperature to the hot forging deformation temperature, then upsetting, punching, and punching the hot section on the press to make a ring blank for rolling. According to the design method of ring blank size, take the rolling ratio is 2.5, is 1, determine the size of the ring blank as: outer radius 407mm, inner radius 177mm, width It is 373mm. ( image 3 shown).

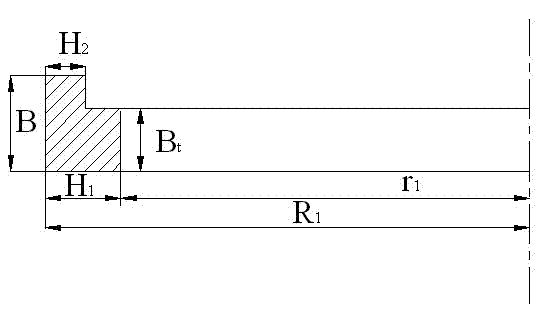

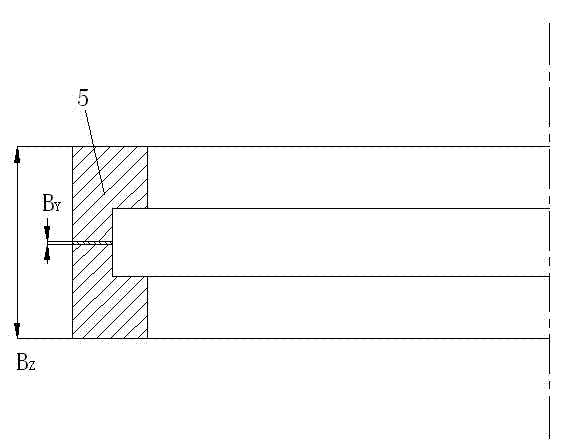

[0061] 2) Rolling pass design: Take the rolling line speed is 1.3m / s, according to the rolling pass design method, according to Figure 4 The structure design shown in the rolling pass, in which: core roll 3 upper and lower w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com