Soft-type semi-high-temperature cooking film and manufacturing method thereof

A technology of high-temperature cooking and production methods, applied to chemical instruments and methods, flexible coverings, packaging, etc., can solve the problems of inconvenient transportation and handling, general impact resistance, and packaging rupture, and achieve convenient production and preparation , the effect of strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

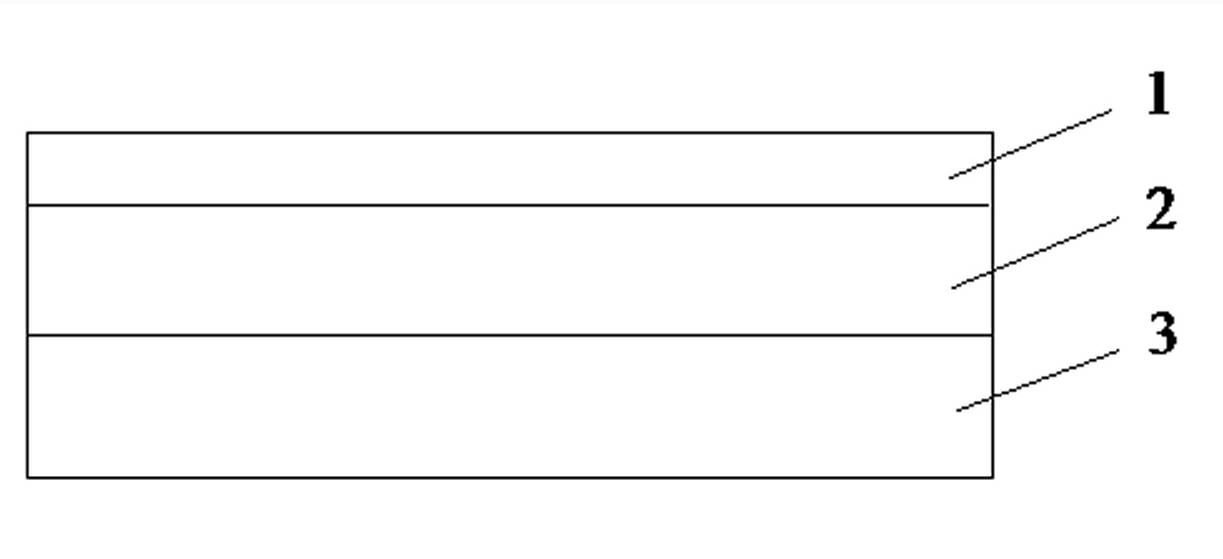

[0023] Semi-high temperature cooking film, its structure is as follows figure 1 As mentioned above, including the heat-sealing layer 1, core layer 2 and corona layer 3 arranged in sequence, the heat-sealing layer 1 is made of polypropylene copolymer, and its melt index is 8-12g / 10min (test conditions: standard caliber 2.095mm, The temperature is 230°C, the load is 2.16kg), and finally the film is obtained by plasticizing and extruding through an extruder, and the core layer 2 is produced by blending propylene homopolymer, which is obtained by plasticizing and extruding through an extruder, and the melt index is 6-8g / 10min (test conditions: standard diameter 2.095mm, temperature 230°C, load 2.16kg), the corona layer 3 is made of propylene / ethylene random copolymer, and the melt index is 6-8g / 10min (test conditions: standard diameter 2.095mm, The temperature is 230°C, the load is 2.16kg), the heat-sealing layer is plasticized and extruded at 230°C, the core layer and the corona...

Embodiment 2

[0028] Soft semi-high temperature cooking film, its structure is as follows figure 1 As mentioned above, including the heat-sealing layer 1, the core layer 2 and the corona layer 3, the heat-sealing layer 1 is made of a propylene copolymer, and its melt index is 8-12g / 10min (test conditions: standard diameter 2.095mm, temperature 230°C, The load is 2.16kg), and finally the film is obtained by plasticizing and extruding through an extruder, and the core layer 2 is produced by blending ethylene-propylene elastomer and propylene homopolymer, which is obtained by plasticizing and extruding through an extruder, and the melt index is 6-8g / 10min (test conditions: standard diameter 2.095mm, temperature 190°C, load 2.16kg), the ethylene content of the ethylene-propylene elastomer is 10%, and the weight ratio of the ethylene-propylene elastomer to the propylene homopolymer is 10:100. The corona layer 3 is made of propylene / ethylene random copolymer with a melt index of 6-8g / 10min (test...

Embodiment 3

[0031] Soft semi-high temperature cooking film, its structure is as follows figure 1As mentioned above, including the heat-sealing layer 1, the core layer 2 and the corona layer 3, the heat-sealing layer 1 is made of a propylene copolymer, and its melt index is 8-12g / 10min (test conditions: standard diameter 2.095mm, temperature 230°C, The load is 2.16kg), and finally the film is obtained by plasticizing and extruding through an extruder, and the core layer 2 is produced by blending ethylene-propylene elastomer and propylene homopolymer, which is obtained by plasticizing and extruding through an extruder, and the melt index is 6-8g / 10min (test conditions: standard diameter 2.095mm, temperature 190°C, load 2.16kg), the ethylene content of the ethylene-propylene elastomer is 10%, and the weight ratio of the ethylene-propylene elastomer to the propylene homopolymer is 30:100. The corona layer 3 is made of propylene / ethylene random copolymer with a melt index of 6-8g / 10min (test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com