Novel fault positioning method

A new type of fault location technology, applied in aircraft component testing, aircraft parts, ground devices, etc., can solve problems such as time-consuming and labor-intensive, and cannot guarantee the effect, and achieve the effect of simple use, strong promotion and application value, and lower operating threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

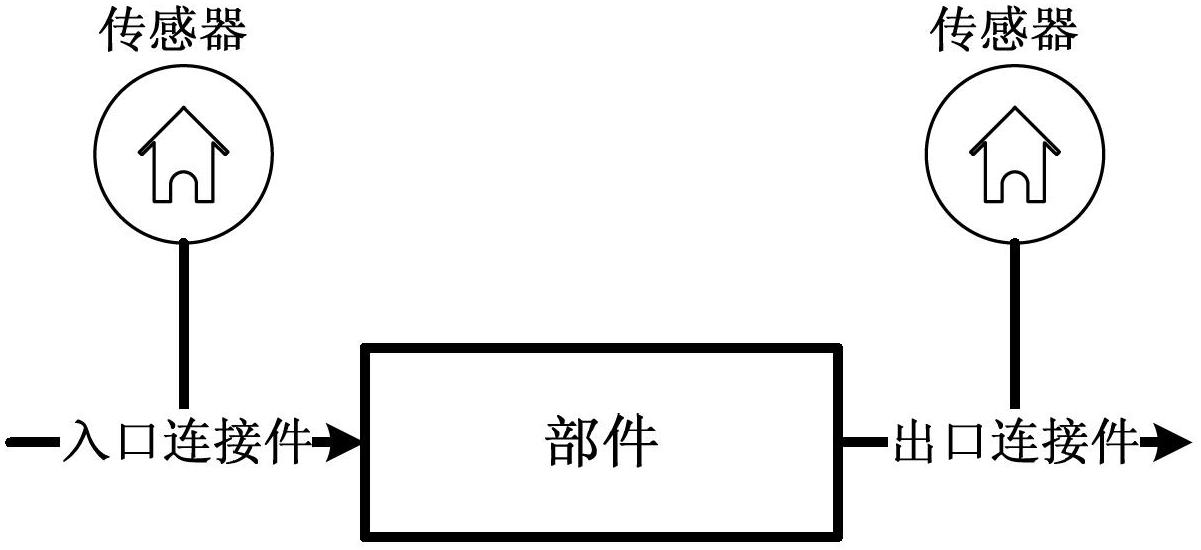

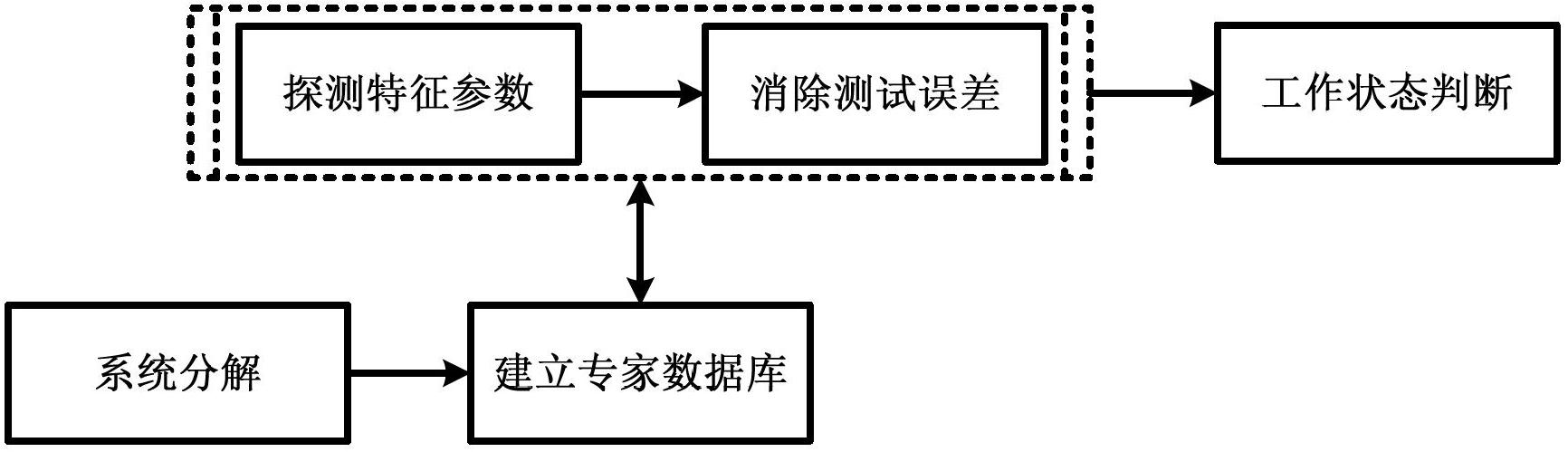

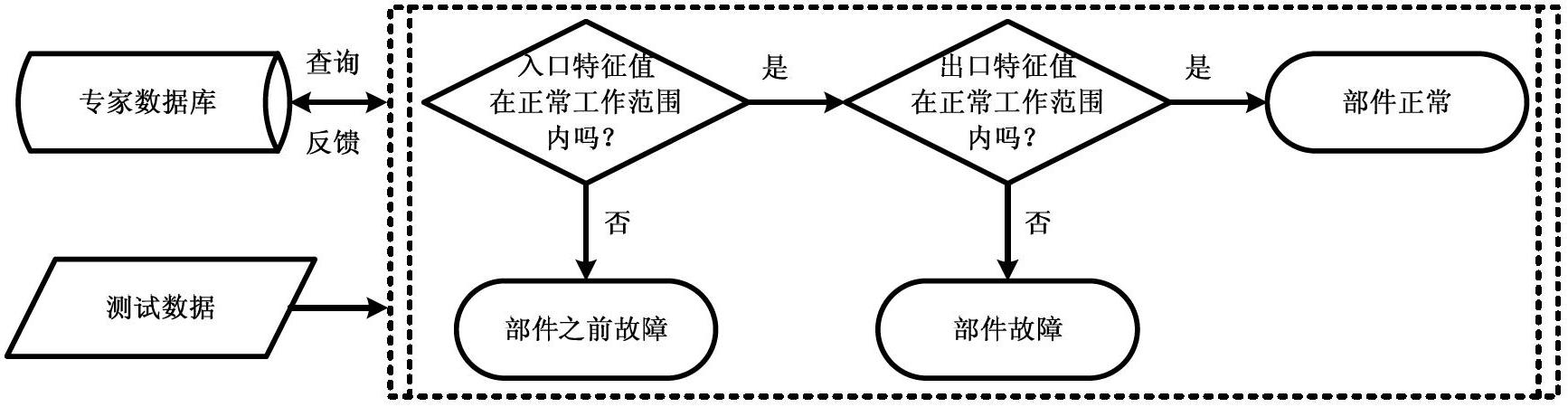

[0047] Taking the aircraft fuel system as an example, combined with figure 2 , the novel fault location method of the present invention is described in detail:

[0048] Step 1. Fuel System Breakdown

[0049] According to the principle of functional independence, the fuel system is decomposed. In this embodiment, the independent components include FR215, FR216, FR25C, front group fuel supply pump, rear group fuel supply pump, etc.;

[0050] Step 2. Establish fuel system expert database

[0051] Taking FR216, an independent component in the fuel system, as an example, the characteristic parameters related to the working state of FR216 include FR216 inlet pressure, FR216 outlet pressure, and FR216 outlet flow. The outlet pressure of FR216 is between 100-120, and the outlet flow of FR216 is between 0-50m3 / h, which are arranged and combined to form the expert database Table 1;

[0052] Table 1

[0053] parts

Entry eigenvalue

Entry eigenvalue

export eigenva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com