Method and system for manufacture of target material

A manufacturing method and target material technology, which is applied in the metal material coating process, ion implantation plating, coating, etc., can solve the problem of irregular etching morphology, inability to characterize the use efficiency of multiple targets, and difficulties in theoretical calculation formulas and other issues to achieve the effect of optimizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

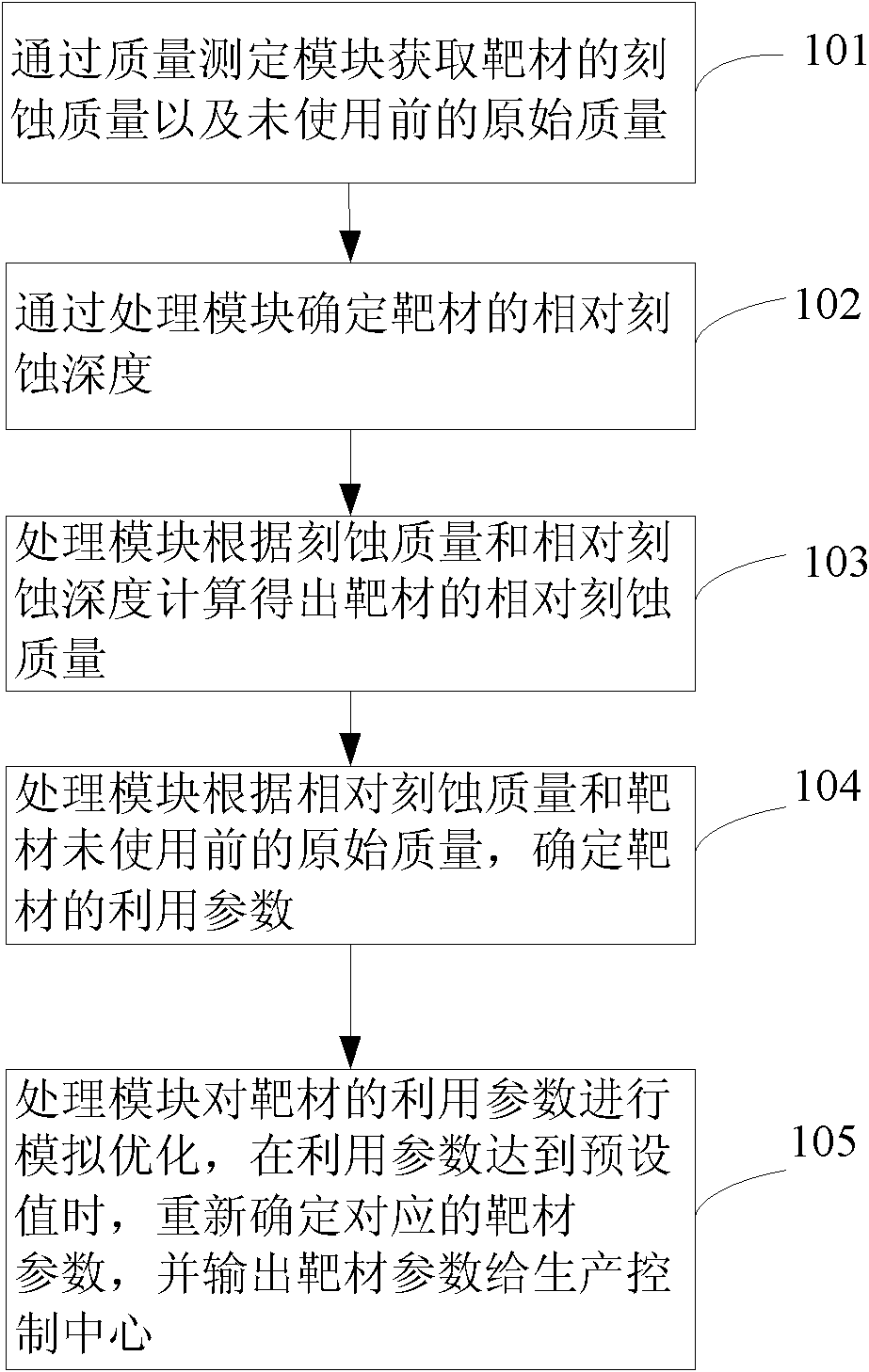

[0051] Embodiments of the present invention provide a method for manufacturing a target, which can optimize the production of the target. Such as figure 1 As shown, this embodiment includes:

[0052] Step 101: Obtain the etching quality of the target and the original quality before use through the quality measurement module;

[0053] Step 102: Determine the relative etching depth of the target through the processing module;

[0054] Step 103: The processing module calculates the relative etching quality of the target according to the etching quality and the relative etching depth;

[0055] Step 104: The processing module determines the utilization parameters of the target according to the relative etching quality and the original qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com