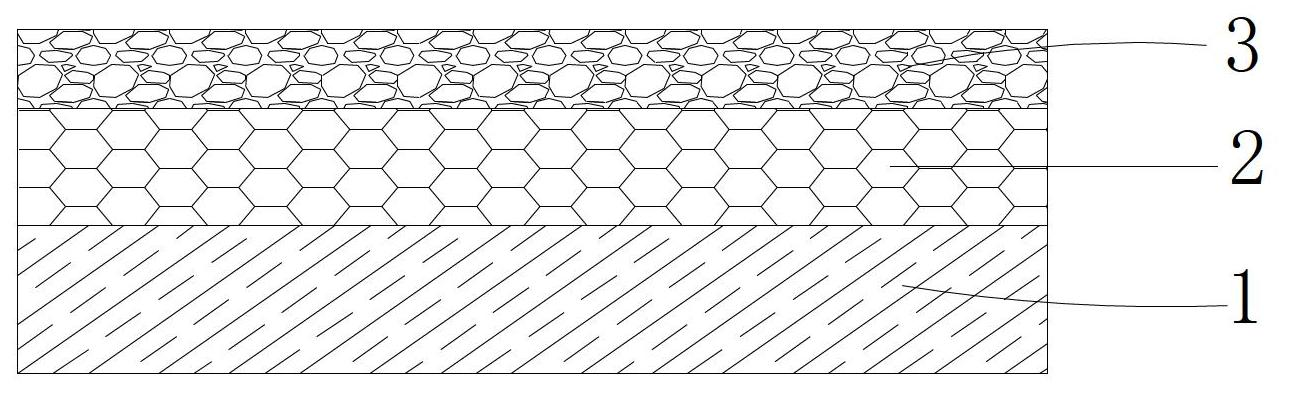

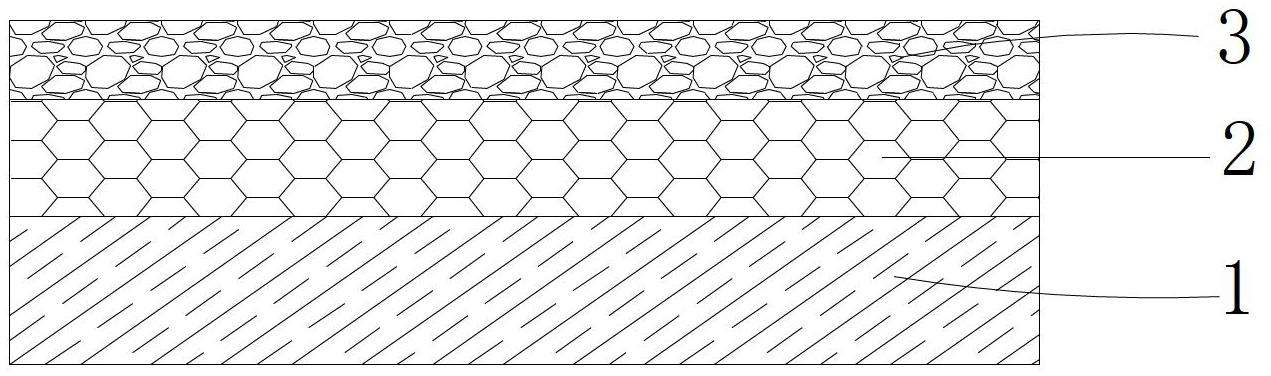

Construction method of noise type asphalt pavement

A construction method and asphalt surface layer technology, which is applied in the field of asphalt pavement construction, can solve problems such as difficulty in pavement construction, and achieve the effects of improving road surface roughness, ensuring molding standards, and improving sound value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] According to the construction method that the above-mentioned specific embodiment provides and the ore powder particle size range that table 2 provides, list the crushed stone that actually applies in the present embodiment and the ore powder are the synthetic grade that is 92%: 8% by weight in table 3 match:

[0039] Table 3: Synthetic gradation of crushed stone and mineral powder

[0040] Mesh size(mm)

[0041] After the completion of the construction, the construction depth of the asphalt surface layer was detected to be 1.6mm, and the PCB 377A02 microphone was used to measure the road surface noise at the set position in the vehicle, satisfying the measurement noise frequency range of 20-2000HZ, and the noise upper and lower limit difference is 3dB high precision requirements.

Embodiment 2

[0043] According to the construction method that the above-mentioned specific embodiment provides and the ore powder particle size range that table 2 provides, list the crushed stone that is actually used in the present embodiment and ore powder are 90%: 10% synthetic by weight ratio with table 4 Grading:

[0044] Table 4: Synthetic gradation of crushed stone and mineral powder

[0045] Mesh size(mm)

[0046] After safe construction, the construction depth of the asphalt surface layer was detected to be 1.3mm, and the PCB 377A02 microphone was used to measure the road surface noise at the set position in the vehicle, satisfying the measurement noise frequency range of 20-2000HZ, and the noise upper and lower limit difference is 3dB high precision requirements.

Embodiment 3

[0048] According to the construction method that the above-mentioned specific embodiment provides and the ore powder particle size range that table 2 provides, list the crushed stone that is actually used in the present embodiment and ore powder are 91%: 9% synthetic by weight ratio with table 5 Grading:

[0049] Table 5: Synthetic gradation of crushed stone and mineral powder

[0050] Mesh size(mm)

[0051] After the completion of the construction, the construction depth of the asphalt surface layer was tested to be 1.45mm, and the PCB 377A02 microphone was used to measure the road surface noise at the set position in the car, satisfying the measurement noise frequency range of 20-2000HZ, and the noise upper and lower limit difference is 3dB high precision requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com