Rock debris cleaning device for drilling tool

A cleaning device and cuttings technology, which is applied in drilling tools, drilling equipment, earthwork drilling and production, etc., can solve the problems of low cleaning efficiency of boreholes, achieve efficient removal of cuttings, efficient removal, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the drawings:

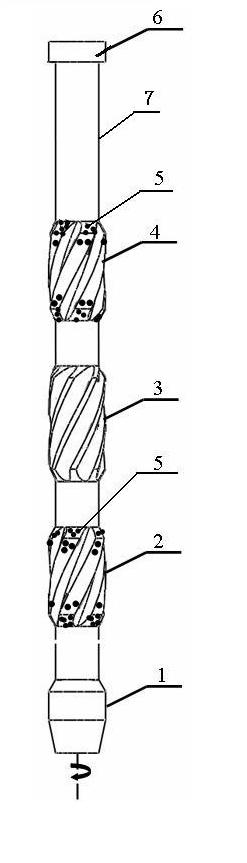

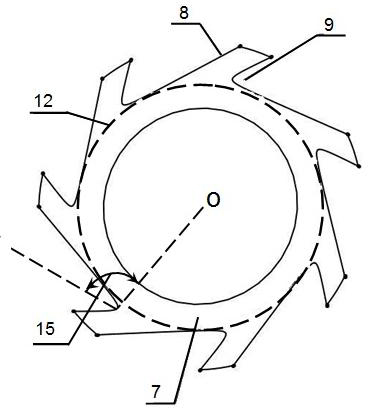

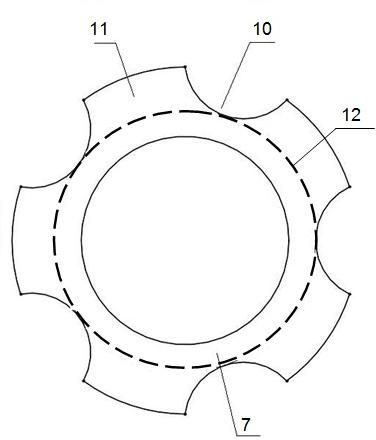

[0040] Such as figure 1 As shown, the cuttings cleaning device used on this drilling tool is made by integral machining of thick-walled steel pipe blanks with non-equal diameters, and mainly includes an upper eye reaming protector 4, a rotary speed increaser 3, and a lower eye reaming protector 2. It is composed of the unmachined body part. Combine figure 2 As shown, the main body 7 is a thick-walled steel pipe, which penetrates inside and has the same inner diameter. The body 7 is used to process the rotary speed increaser 3, the lower reamer protector 2, and the upper eye reamer protector 4. The wall thickness of the part of the tube wall is larger than the other parts. The eye reaming protector 2 and the upper eye reaming protector 4 are suitable, and the tube wall thickness of the remaining part of the body 7 is relatively thin. One end of the body 7 is a male connector 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com