Fluid power machine

A power machine and fluid technology, applied in the direction of engines, wind engines, machines/engines, etc., can solve the problems of large transmission shock and unstable operation, and achieve the effects of stable operation, large frontal flow area, and high fluid kinetic energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

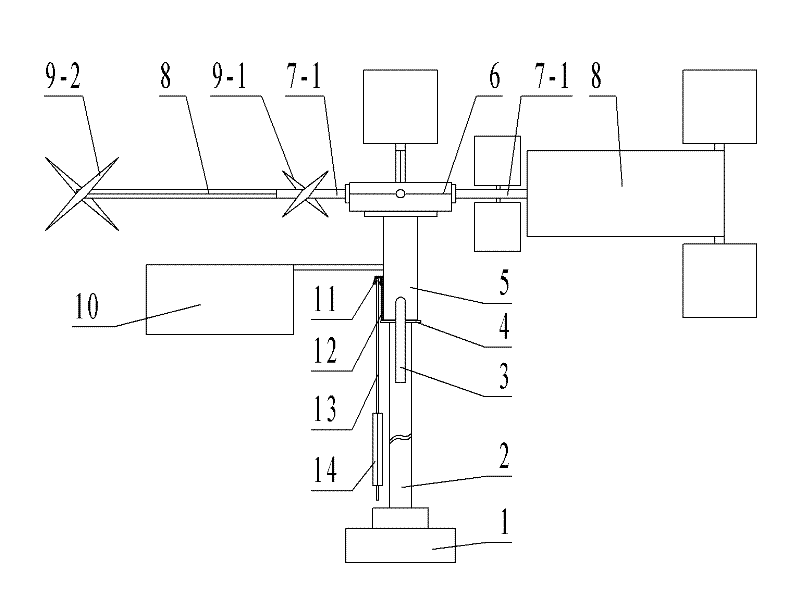

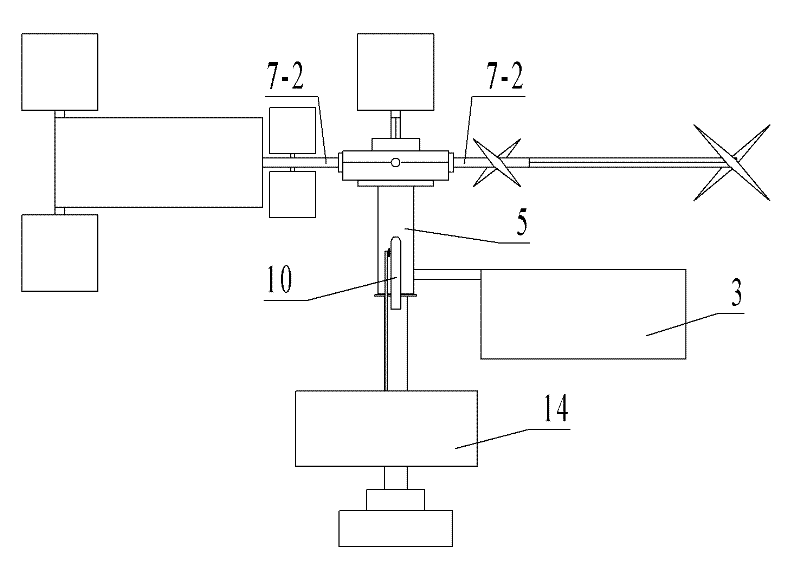

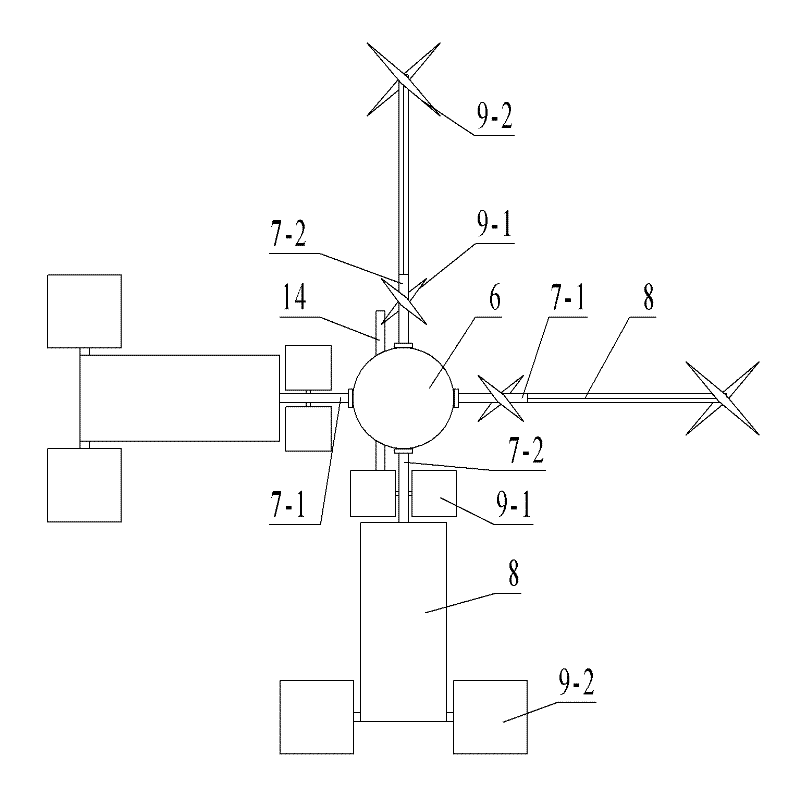

[0020] This embodiment includes an organic base 1, a hollow shaft 2, a balance plate 3, an orifice plate 4, a rudder plate hinge 5, a blade shaft frame 6, a blade shaft A7-1, a blade shaft B7-2, a main drive blade 8, and an auxiliary drive Blade 9, rudder plate 10, suspension plate gear 11, lock pin 12, swing lever 13, driving suspension plate 14, output shaft 15, cam 16, blade shaft joint A17-1, blade driving gear A17-11, blade shaft joint B17 -2, blade drive gear B17-21, double-tooth movable rack 18-1, single-tooth movable rack 18-2, cam drive pin 19, guide wheel 20, dust cover 21.

[0021] Figure 1 to Figure 5 The fluid power machine shown includes an output shaft 15, main drive blades 8, a hollow shaft 2 and a base 1, the hollow shaft 2 is welded on the base 1, the output shaft 15 is sleeved in the hollow shaft 2, and the hollow shaft 2 is A slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com