Edge type backlight module

A side-entry backlight and module technology, which is applied in the field of side-entry backlight modules, can solve the problems of unfavorable cost control, heavy backlight module, and relatively large fluctuations in backplane costs, so as to achieve light weight and reduce production costs , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

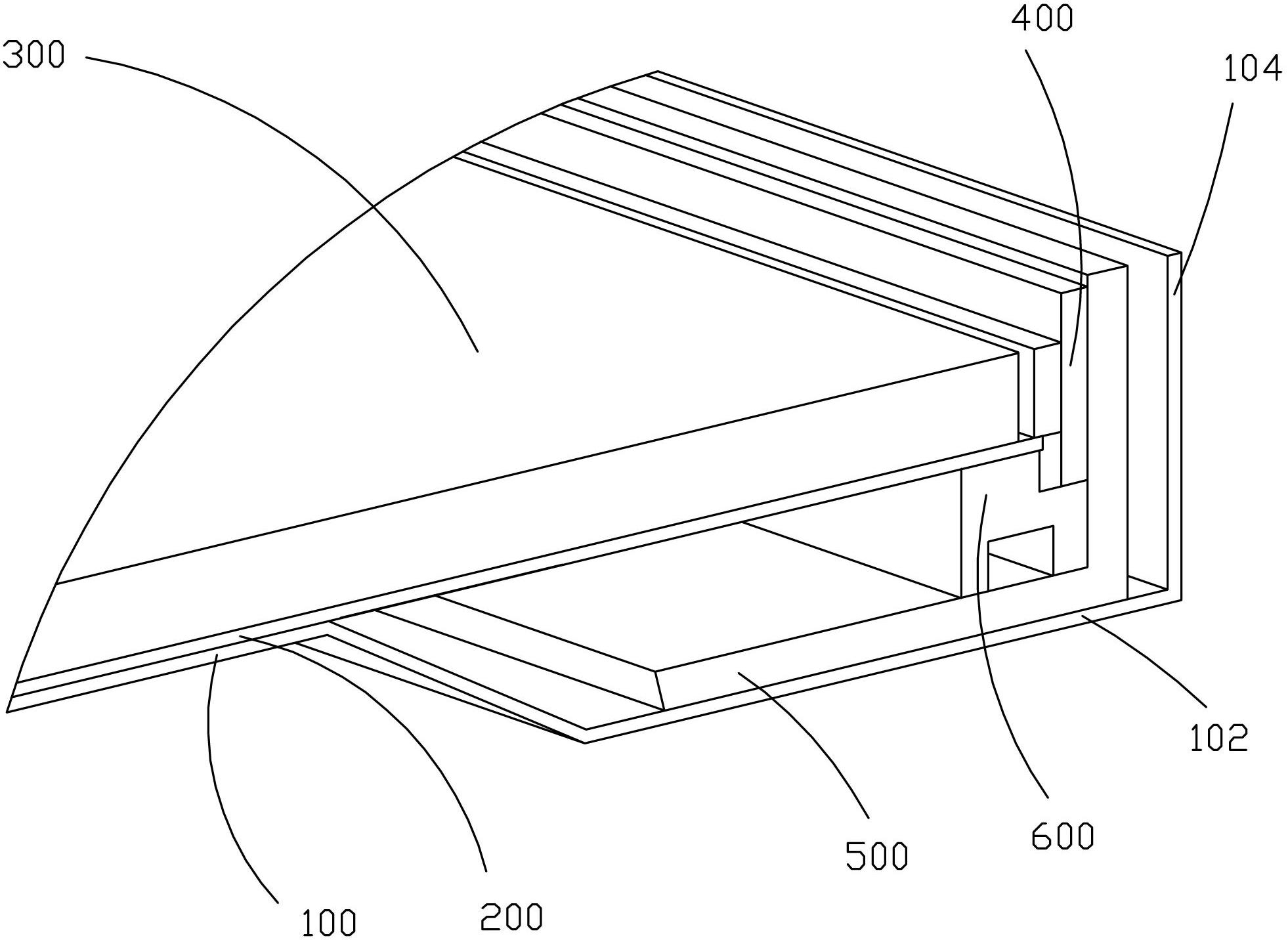

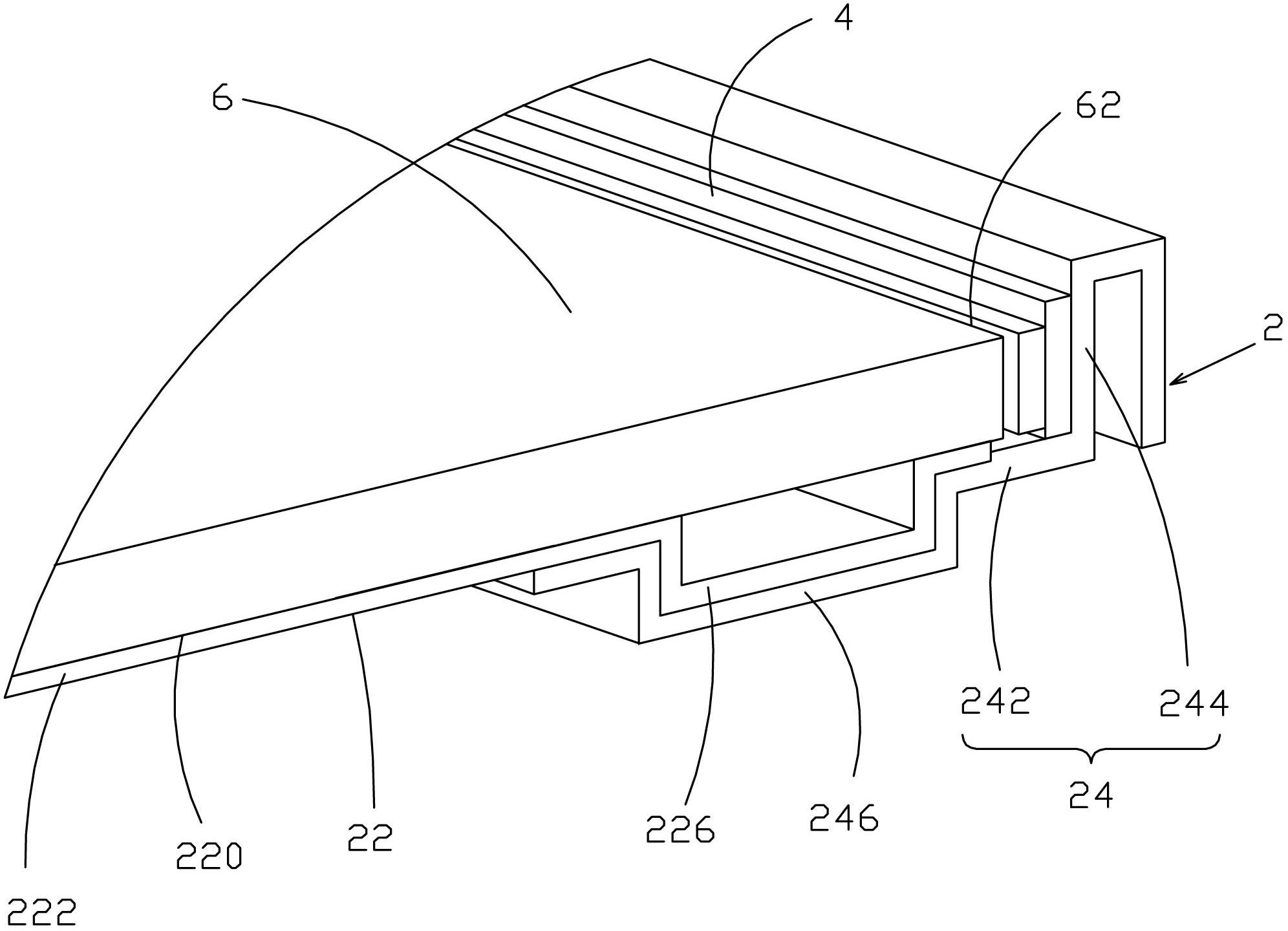

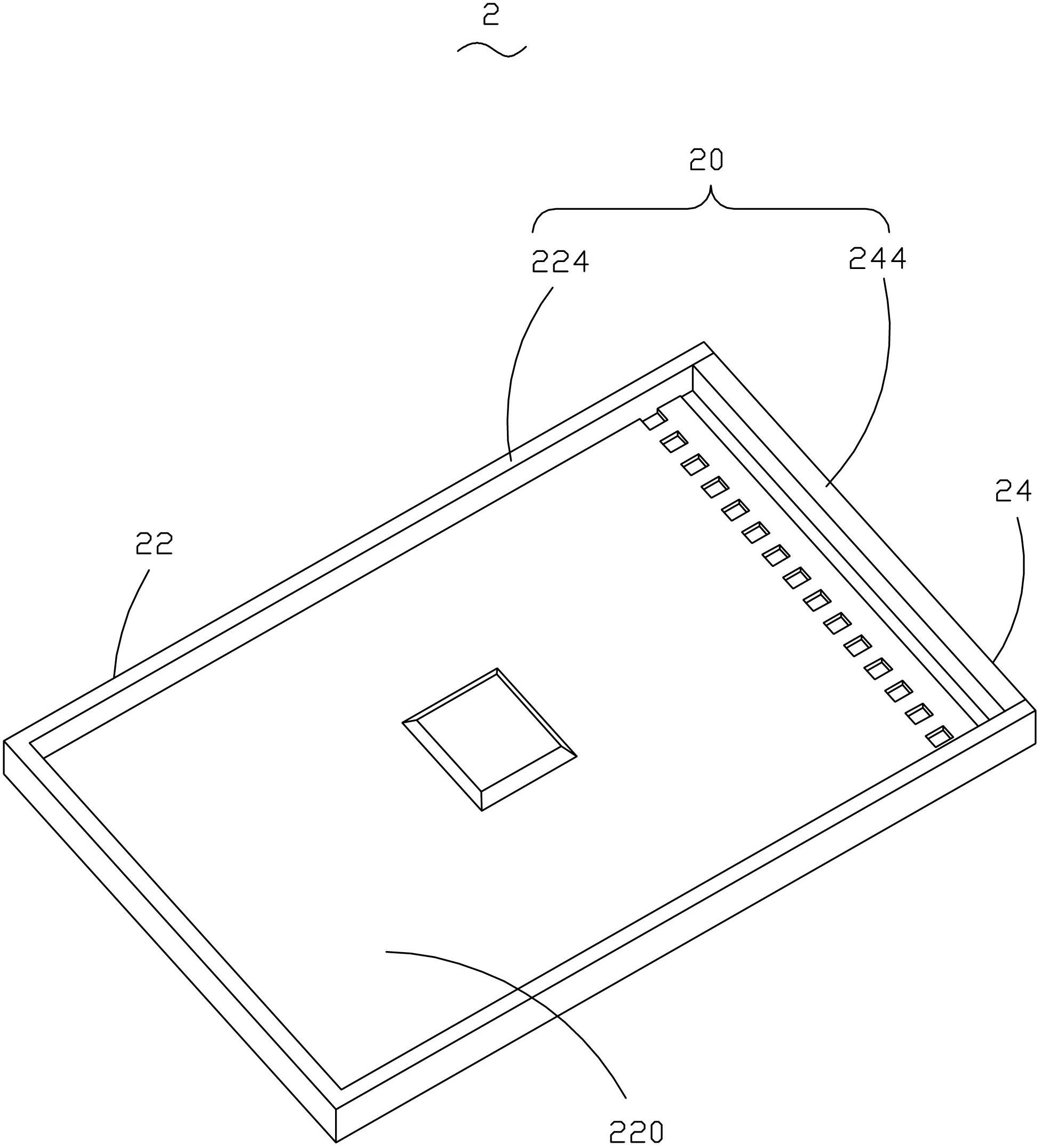

[0026] see Figure 2 to Figure 4 The present invention provides a side-entry backlight module, comprising: a backplane 2, a backlight 4 disposed in the backplane 2, and a light guide plate 6 disposed in the backplane 2, the backplane 2 includes a body 22 and The bracket 24 is connected to the body 22 , the body 22 is made of plastic material, the bracket 24 is made of metal material, and the backlight 4 is installed on the bracket 24 . Preferably, the body 22 is made of plastic material with high reflectivity, and the bracket 24 is made of metal material with high thermal conductivity. The plastic material can be selected from thermoplastic (Thermoplastic), such as PC (Polycarbonate, polycarbonate resin), PA (Polyamide, polyamide), etc. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com