Half-perforated foam sound absorbing structure with variable connectivity rate

A technology with semi-open cells and high connectivity, which is applied in the direction of sound-generating devices and instruments, and can solve the problems of good high-frequency sound absorption performance and poor low-frequency sound absorption performance of semi-open-cell foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

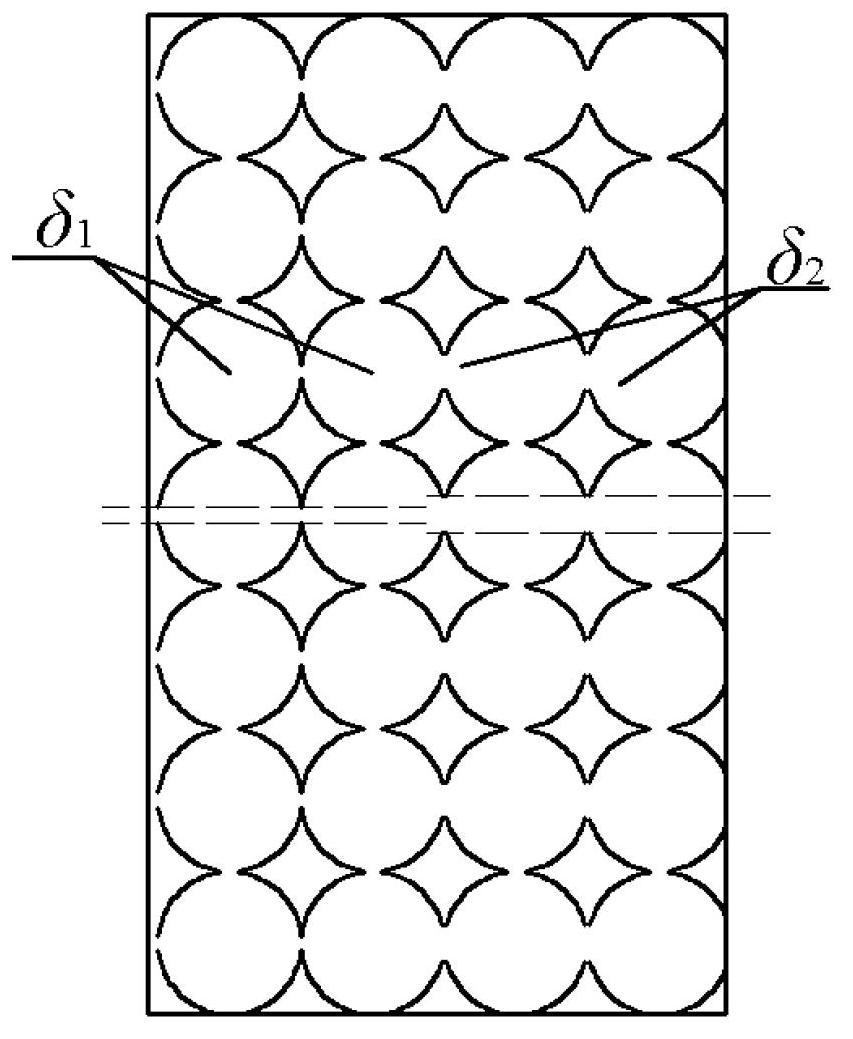

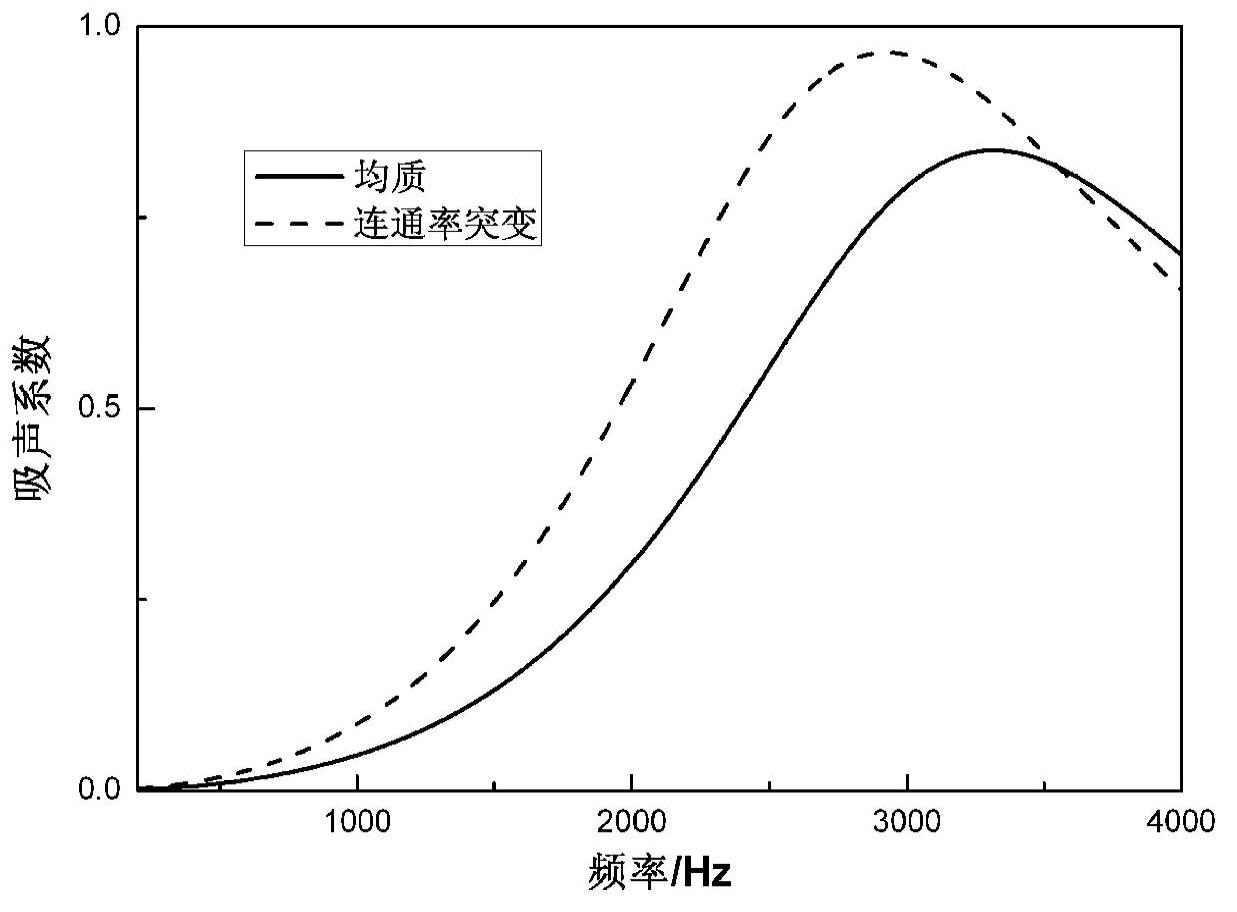

[0019] Assume that there is a homogeneous semi-open cell foam with a thickness of 10mm along the sound incident direction, a connectivity rate of 0.25, a pore diameter of 1.24mm, and a porosity of 66.8%. Change the connectivity rate of the first 5mm to 0.2, and the connectivity rate of the rear 5mm to 0.3. The homogeneous semi-open-cell foam has the same mass and volume as the semi-open-cell foam with a sudden change in connectivity, but the sound absorption performance at low and medium frequencies has increased by 30% to 40%. image 3 Shown is the comparison of the sound absorption performance of the semi-open-cell foam with a sudden change in connectivity rate and the homogeneous semi-open-cell foam in this embodiment.

Embodiment 2

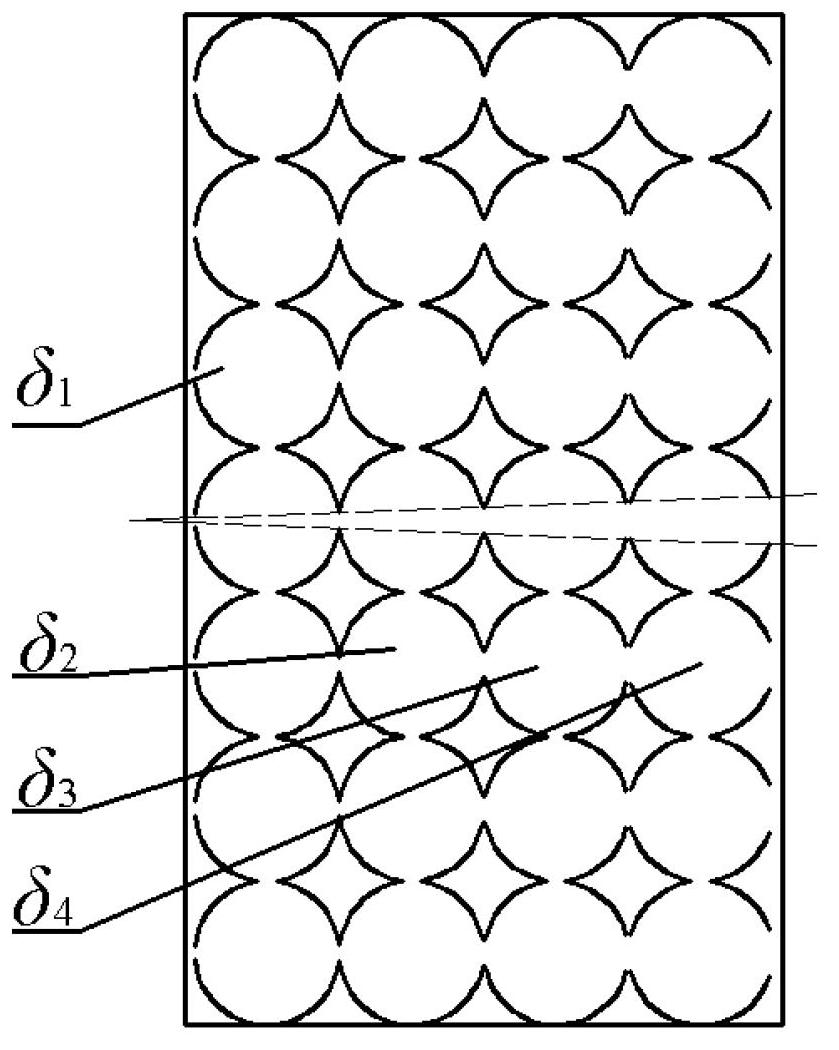

[0021] Assume that there is a homogeneous semi-open cell foam with a thickness of 10mm along the sound wave incident direction, a pore diameter of 1.24mm, a connectivity rate of 0.25, and a porosity of 66.8%. Vary the connectivity ratio linearly from 0.16 to 0.34 along the direction of acoustic wave incidence. The connectivity rate increases linearly. The semi-open-cell foam has the same mass and volume as the homogeneous semi-open-cell foam, but the mid-low frequency sound absorption performance is improved by 30% to 50%. For example, Figure 4 Shown is the comparison of the sound absorption properties of the semi-open-cell foam with linearly increasing connectivity rate and the homogeneous semi-open-cell foam in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com