Pin type plug seedling transplanting end effector

A technology of end effector and plug seedlings, which is applied in the field of agricultural machinery, can solve the problems of large resistance to entry into the soil, long size of the end effector, and large operation resistance, etc., and achieve smooth entry into the soil, good versatility, and good force transmission characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

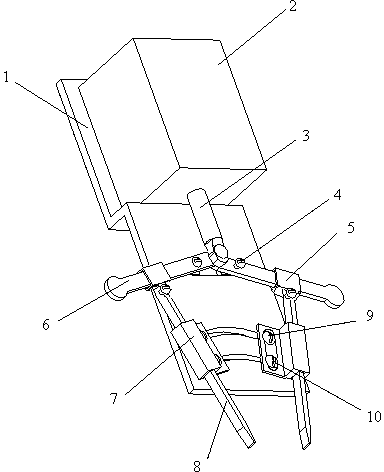

[0013] Such as figure 1 As shown, the pin-type hole tray seedling transplanting end effector consists of a housing back plate 1, an electromagnet 2, an electromagnet push rod 3, two horizontal groove inner sliders 4, two swing rod sliders 5, two It consists of a swing rod 6, two sliding sleeves 7, two pins 8, two upper bolts and nuts 9 and two lower bolts and nuts 10.

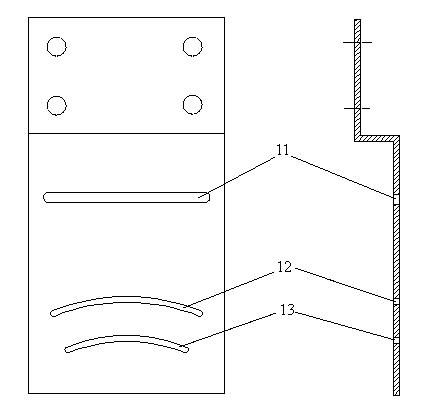

[0014] Such as figure 2 As shown, the housing back plate 1 is provided with a horizontal slot 11 , and a large arc slot 12 and a small arc slot 13 . The horizontal slot 11, the large arc slot 12, and the small arc slot 13 are all left-right symmetrical, and the common center of the large arc slot 12 and the small arc slot 13 is located below the centerline of the shell back plate 1.

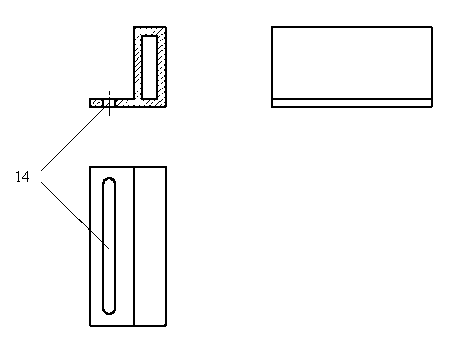

[0015] Such as image 3 As shown, the sliding sleeve 7 is provided with a coupling through groove 14 .

[0016] The electromagnet 2 is fixed on the shell back plate 1, and the electromagnet push rod 3 protrudes from the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com