Mixed granulated honey and preparation method thereof

A technology of crystallization and crystallization inducer, which is applied in the field of food, can solve the problems of single taste and long crystallization time, and achieve the effect of simple preparation process, easy storage and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

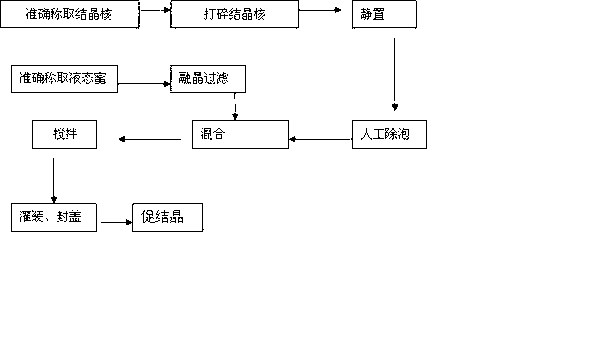

Method used

Image

Examples

Embodiment 1

[0025] Mixed crystalline honey A of the present invention:

[0026] (1) Using 10 parts by weight of rapeseed honey crystalline honey and 5 parts by weight of linden honey crystalline honey as the crystallization inducer (crystallization nucleus), the crystallization inducer is ground with a colloid mill, filtered, and left to stand for 2 h -3 h, Remove the foam on the surface manually, and reserve honey;

[0027] (2) Take 15 parts by weight of acacia honey, 56 parts by weight of rapeseed honey and 14 parts by weight of bitter bean honey, filter and cool to 20°C-25°C, mix and stir with the above-mentioned spare honey for 10 hours, let stand for 10 hours, and manually remove surface foam;

[0028] (3) After filling and capping, the product is stored in a constant temperature room at 13°C to 14°C for 6 days to promote crystallization to obtain the mixed crystalline honey A of the present invention.

Embodiment 2

[0030] Mixed crystalline honey B of the present invention:

[0031] (1) Using 15 parts by weight of lychee crystallized honey as a crystallization inducer (crystallization nucleus), grind the crystallization inducer with a colloid mill, filter, let it stand for 2 hours to 3 hours, manually remove the surface foam, and obtain spare honey;

[0032] (2) Take 14 parts by weight of acacia honey, 55 parts by weight of rapeseed honey and 16 parts by weight of bitter bean honey, filter and cool to 20°C-25°C, mix and stir with the above-mentioned spare honey for 9 hours, let stand for 12 hours, and manually remove surface foam;

[0033] (3) After filling and capping, the product is stored in a constant temperature room at 13°C to 14°C for 7 days to promote crystallization to obtain the mixed crystallized honey B of the present invention.

Embodiment 3

[0035] Mixed crystalline honey C of the present invention:

[0036] (1) Using 7 parts by weight of citrus crystallized honey and 8 parts by weight of Vitex quintana crystallized honey (crystal nucleus), grind the crystallization inducer with a colloid mill, filter it, let it stand for 2 hours to 3 hours, and manually remove the surface foam to obtain reserve honey;

[0037] (2) Take 16 parts by weight of acacia honey, 55 parts by weight of rapeseed honey and 14 parts by weight of bitter bean honey, filter and cool to 20°C-25°C, mix and stir with the above spare honey for 9 hours, let stand for 12 hours, and manually remove surface foam;

[0038] (3) After filling and capping, the product is stored in a constant temperature room at 13°C to 14°C for 7 days to promote crystallization to obtain the mixed crystallized honey C of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com