Cigarette quality on-line detection device and detection method based on machine vision

A machine vision and detection device technology, applied in the field of tobacco machinery, can solve the problems of inability to realize online detection, difficult to achieve, complex and urgent detection tasks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

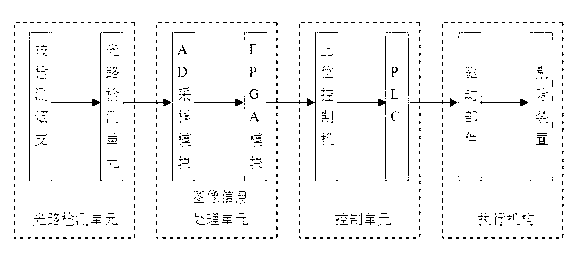

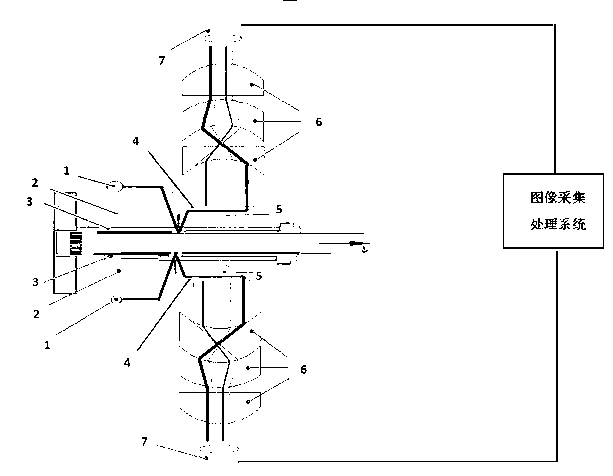

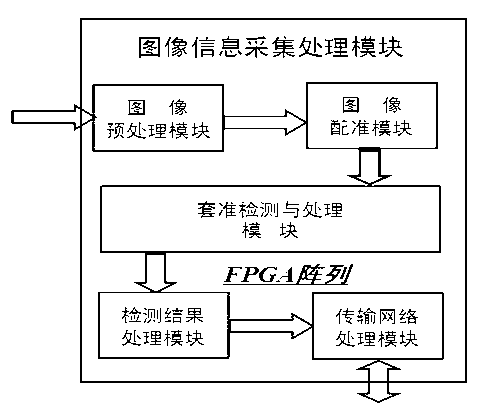

[0013] exist figure 1 and figure 2 Among them, the online inspection device for cigarette quality based on machine vision includes four parts: an optical path detection unit, an image information processing unit, a control unit, and an actuator. The cigarette passes through the protective glass tube 3 at high speed, and the optical path detection unit uses the same two sets of devices. Symmetrically installed on both sides of the protective glass tube 3, mainly including white LED light source 1, optical components 2, reflector 5, cylindrical mirror 4, lens 6 and high-speed CCD line scan camera 7; the image information processing unit mainly includes A / D Sampling module and FPGA image information acquisition and processing module; control unit includes upper control machine and PLC; executive mechanism mainly includes driving parts and mechanical rejecting device; sampling information of high-speed CCD line array camera passes A / D sampling module and FPGA image information pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com