Irbesartan capsules and preparation method thereof

A technology of irbesartan and capsules, which is applied in the field of medicine and can solve problems such as low efficiency, high cost, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of embodiment 1 irbesartan capsule

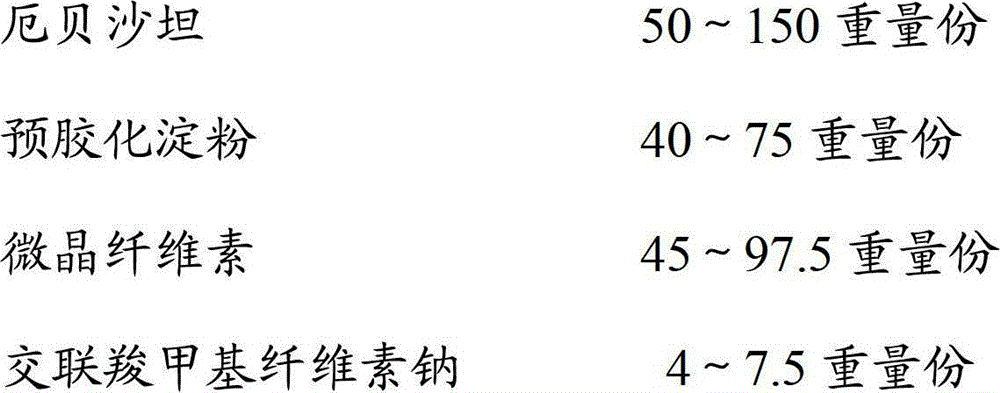

[0027] Irbesartan capsules mainly contain the following components:

[0028]

[0029] The preparation method is as follows:

[0030] a. take the hypromellose of prescription quantity, be dissolved in appropriate amount of purified water, make 3% hypromellose aqueous solution, standby as adhesive;

[0031] b. Pass irbesartan through a No. 5 sieve, pregelatinized starch, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through a No. 6 sieve respectively, and set aside;

[0032] c. Put the sieved irbesartan, pregelatinized starch, microcrystalline cellulose, and croscarmellose sodium in a boiling one-step granulator, set the inlet air temperature to 50°C, and The frequency conversion is 25.00Hz, the air outlet temperature is 50°C, mix evenly, and then spray the adhesive through the spray gun above the boiling one-step granulator, the spray speed is 20.0r / min, the spray gun atomization ...

Embodiment 2

[0037] The preparation method of embodiment 2 irbesartan capsules

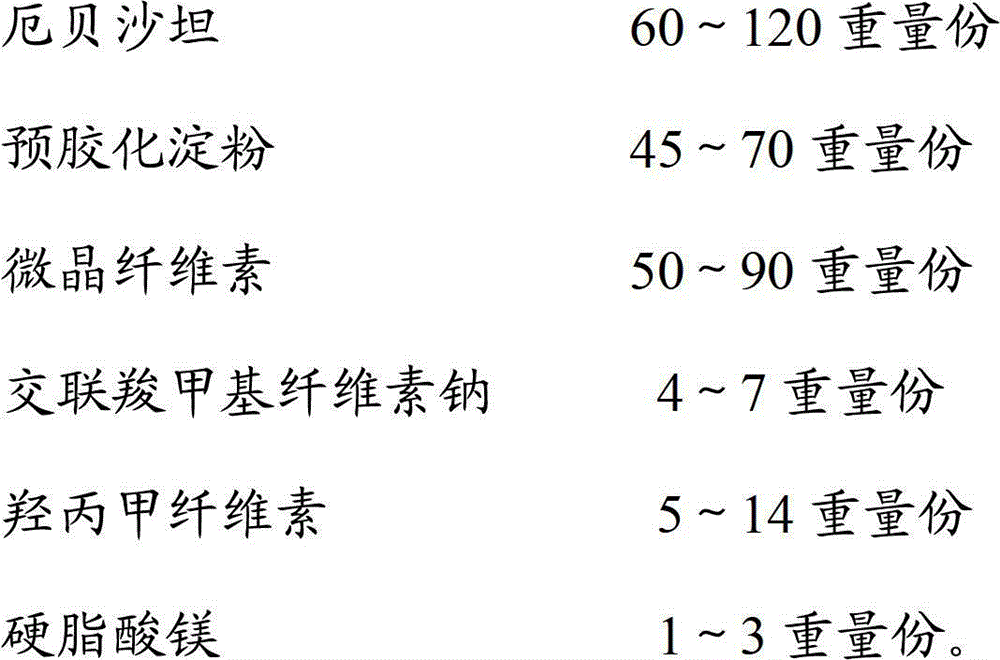

[0038] Irbesartan capsules mainly contain the following components:

[0039]

[0040] The preparation method is as follows:

[0041] a. take by weighing the hypromellose of prescription quantity, be dissolved in appropriate amount of purified water, make 5% hypromellose aqueous solution, standby as adhesive;

[0042] b. Pass irbesartan through a No. 4 sieve, pregelatinized starch, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through a No. 5 sieve respectively, and set aside;

[0043] c. Put the sieved irbesartan, pregelatinized starch, microcrystalline cellulose, and croscarmellose sodium in a boiling one-step granulator, set the inlet air temperature to 50°C, and The frequency conversion is 25Hz, the outlet air temperature is 50°C, mix evenly, and then spray the adhesive through the spray gun above the boiling one-step granulator, the injection speed is 25.0r / min, the spray gu...

Embodiment 3

[0048] The preparation method of embodiment 3 irbesartan capsules

[0049] Irbesartan capsules mainly contain the following components:

[0050]

[0051] The preparation method is as follows:

[0052] a. take the hypromellose of prescription quantity, be dissolved in appropriate amount of purified water, make 4% hypromellose aqueous solution, standby as adhesive;

[0053] b. Pass irbesartan through a No. 5 sieve, pregelatinized starch, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through a No. 5 sieve, and set aside;

[0054] c. Put the sieved irbesartan, pregelatinized starch, microcrystalline cellulose, and croscarmellose sodium in a boiling one-step granulator, set the inlet air temperature to 55°C, and The frequency conversion is 25Hz, the outlet air temperature is 50°C, mix evenly, and then spray the adhesive through the spray gun above the boiling one-step granulator, the injection speed is 30.0r / min, the spray gun pressure is 0.25Mpa, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com