Air blowing type fast and environment-friendly gas generator

A gas generating device and an environmentally friendly technology, which are applied in the directions of gas generating devices, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of simple operation, low center of gravity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

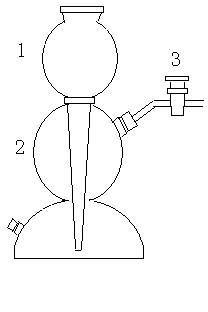

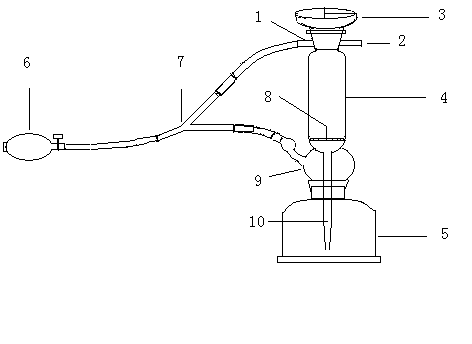

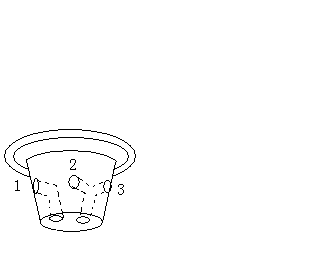

[0020] The blasting type quick and environment-friendly gas generating device of the present invention (such as figure 2 ): Now the structure and connection mode of each part of the present invention will be explained as necessary: (1) porous piston cover (such as image 3 ): It is a glass entity with positioning marks engraved on the top of the cover, and the bottom of the cover is in the shape of a truncated cone. image 3 1 and image 3 Middle 3), in the two semicircles divided by this diameter, a hole is also set at the midpoint of one of the semicircle arcs (such as image 3 middle 2); image 3 Middle 1 hole extends inward along the radius to one-half of the radius and penetrates vertically downwards (leading to the tubular vertical generator). This is an air-filling hole, which is used to fill the tubular vertical generator with air; image 3 Medium 2 holes and image 3 The middle 3 holes extend towards the bisector of the central angle formed by the two holes and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com