Method for producing packaging steel

A technology for packaging and steel plates, used in the manufacture of tools, transportation and packaging, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

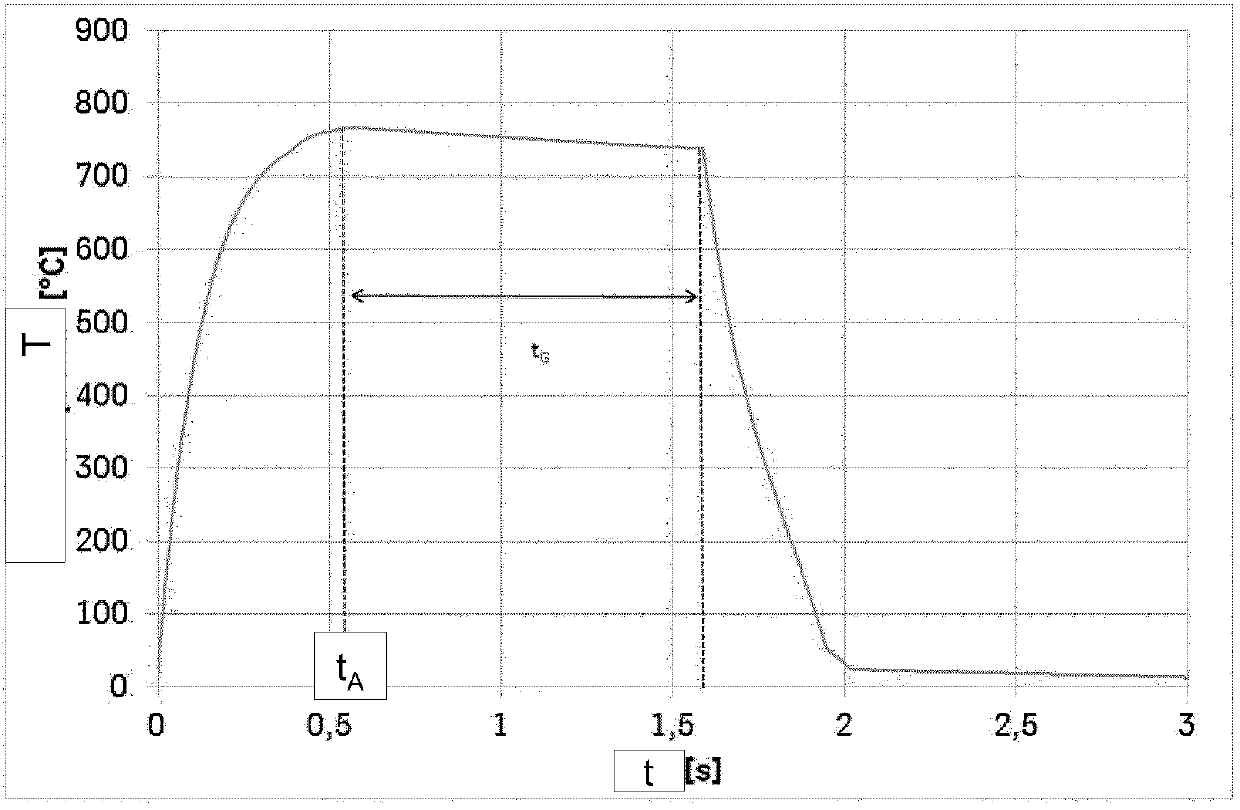

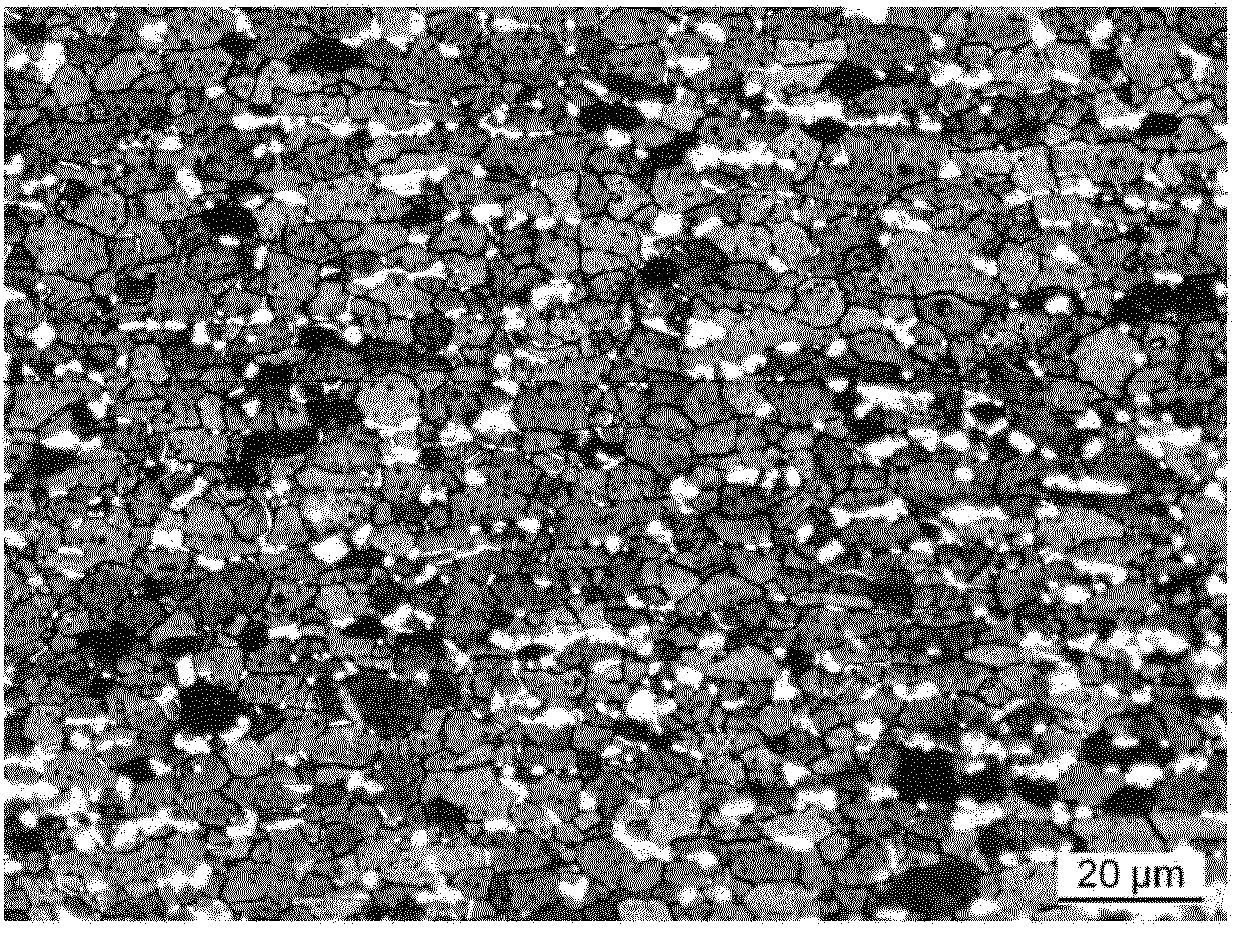

Image

Examples

Embodiment Construction

[0017] Elaborate the present invention according to an embodiment below:

[0018] In order to produce the steel sheet according to the invention as an example of packaging steel, the steel strip produced by continuous casting and hot rolled and wound on the coil consists of a steel with the following composition:

[0019] -C: 0.1% max;

[0020] -N: 0.02% max;

[0021] - Mn: maximum 0.5%, preferably less than 0.4%;

[0022] - Si: maximum 0.04%, preferably less than 0.02%;

[0023] - Al: maximum 0.1%, preferably less than 0.05%;

[0024] - Cr: maximum 0.1%, preferably less than 0.05%;

[0025] -P: 0.03% max,

[0026] -Cu: 0.1% max,

[0027] -Ni: 0.1% max,

[0028] -Sn: 0.04% max,

[0029] -Mo: 0.04% max,

[0030] -V: 0.04% max;

[0031] - Ti: maximum 0.05%, preferably less than 0.02%;

[0032] - Nb: maximum 0.05%, preferably less than 0.02%;

[0033] -B: 0.005% max

[0034] - and other alloy constituents, including impurities: max. 0.05%;

[0035] - The rest is iron....

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com