Decladding device of decladding machine

A technology of peeling machine and wire passing wheel, which is applied in the direction of metal extrusion cleaning equipment, metal processing equipment, manufacturing tools, etc., which can solve the problems of poor peeling effect and inability to adjust the bending degree of wire rod to achieve the operation Convenience, enhanced peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

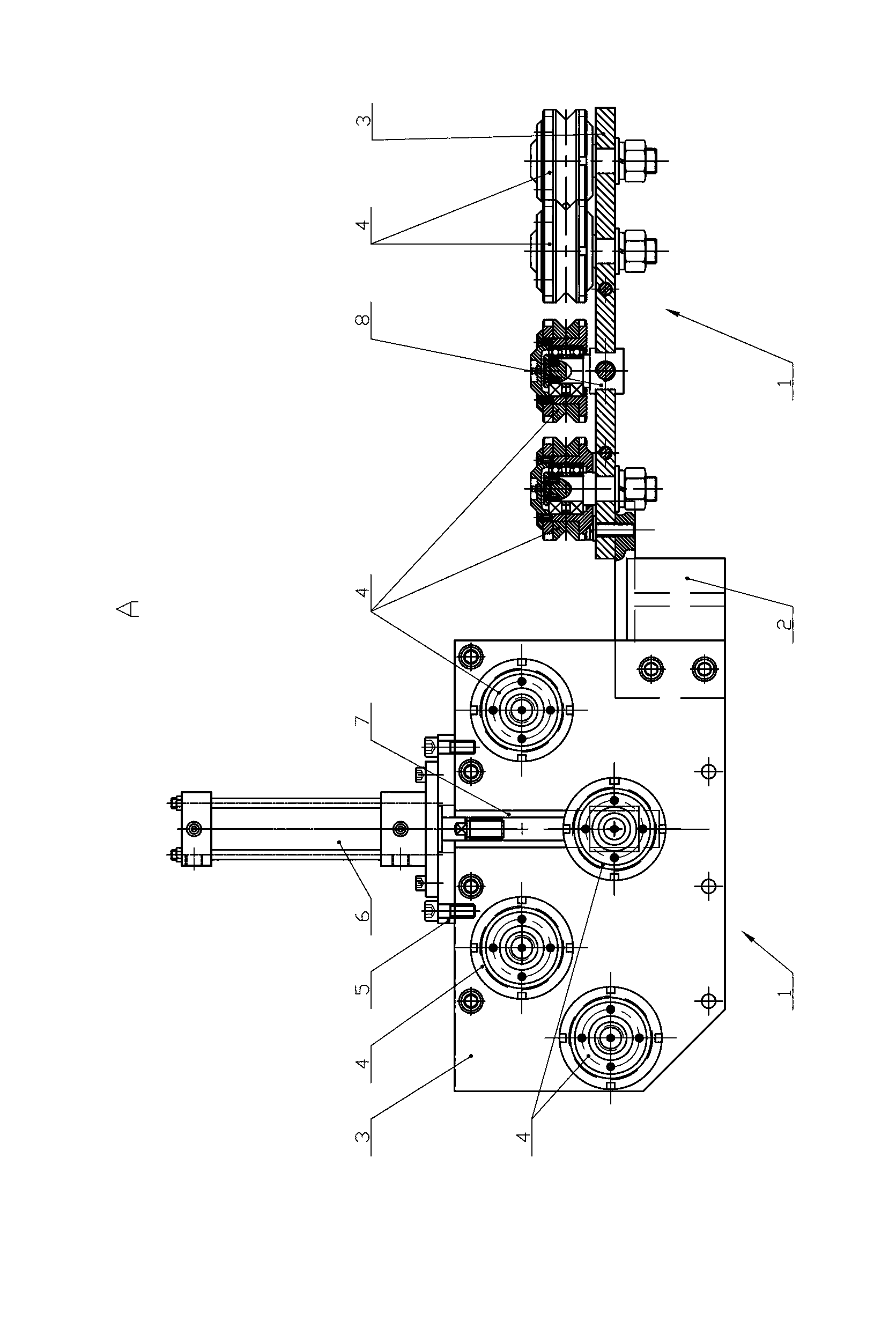

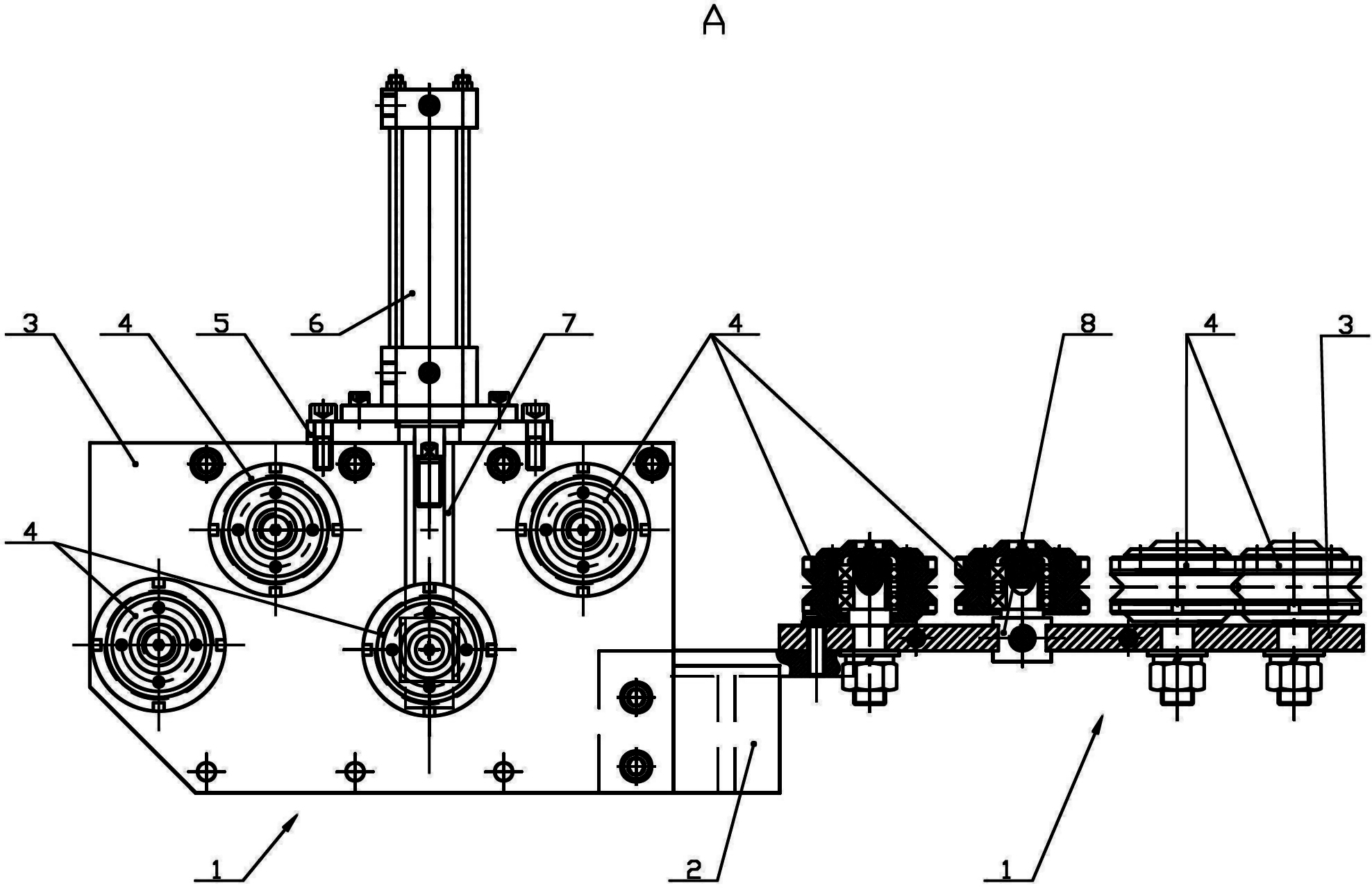

[0015] figure 1 , figure 2 Among them, four-wheel shelling mechanism 1, bracket 2, fixed plate 3, wire passing wheel 4, connecting plate 5, driving element 6, chute 7, slider 8, etc. are included.

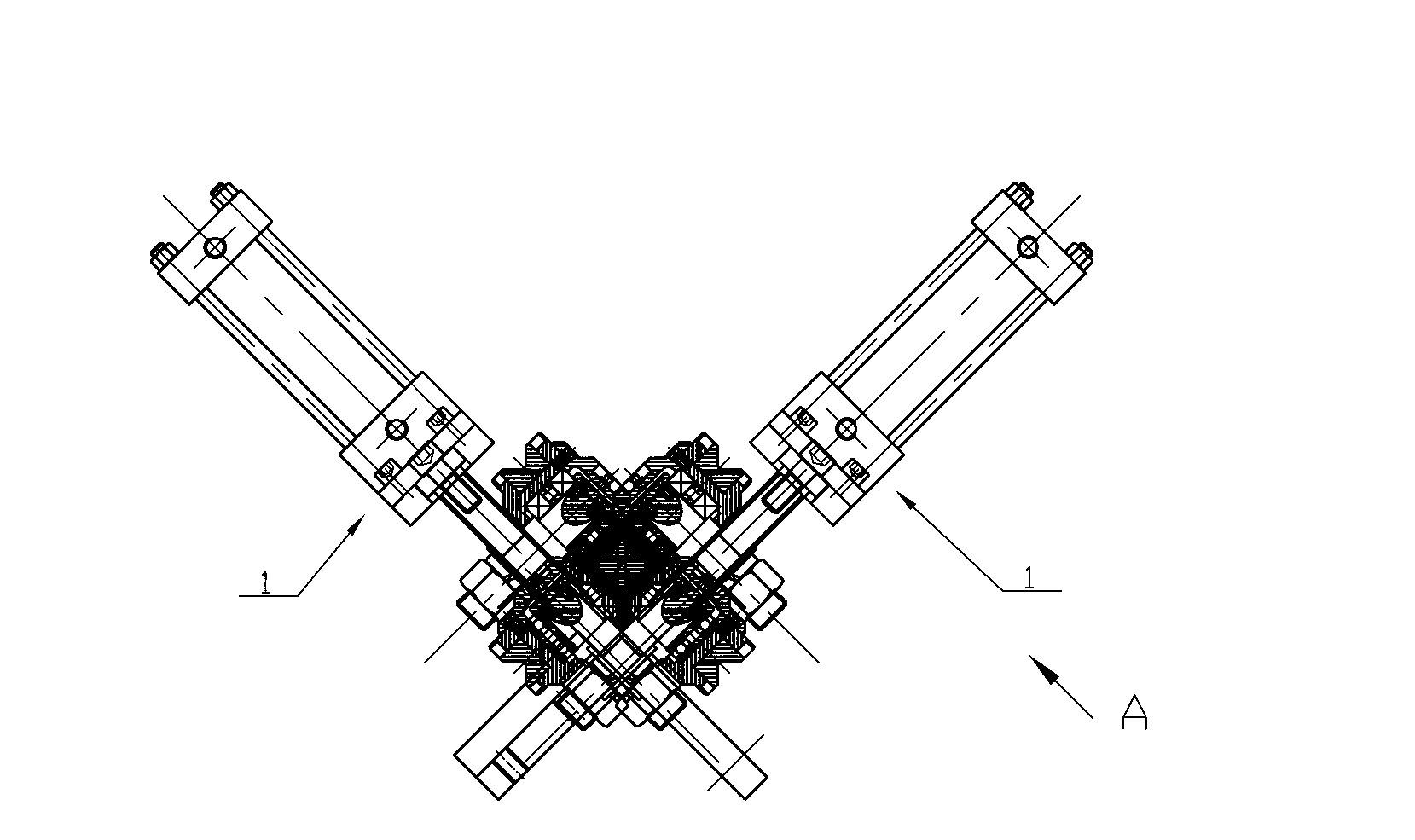

[0016] like figure 1 As shown, the present invention is a shelling device of a peeling machine, comprising two four-wheel shelling mechanisms 1 connected in series and forming an angle of 90° to each other, and a bracket 2 is arranged between the two four-wheel shelling mechanisms 1 , are connected into one body through bracket 2.

[0017] like figure 2 As shown, each four-wheel shelling mechanism 1 includes a fixed plate 3 and four wire passing wheels 4 installed on the fixing plate 3, and the rim of the wire passing wheel 4 has a V-shaped groove. The four wire passing wheels 4 are divided into upper and lower two rows and arranged stagge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com