A horizontal CNC five-axis drilling, milling and tapping machine

A special machine, horizontal technology, applied in the field of horizontal CNC five-axis drilling, milling and tapping special machines, can solve the problem that the main shaft cannot achieve secondary feeding or more feeding, and the operation and processing accuracy are not as good as CNC control, The accuracy of the processing depth cannot be controlled, and the overall appearance and safety performance are improved, the processing technology range is expanded, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

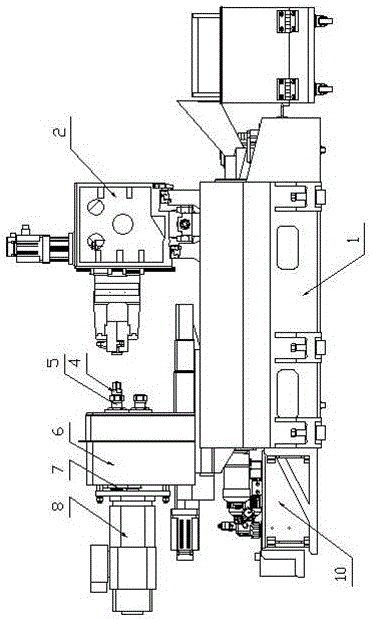

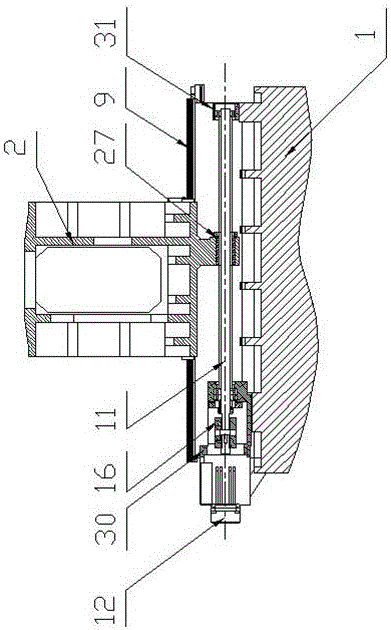

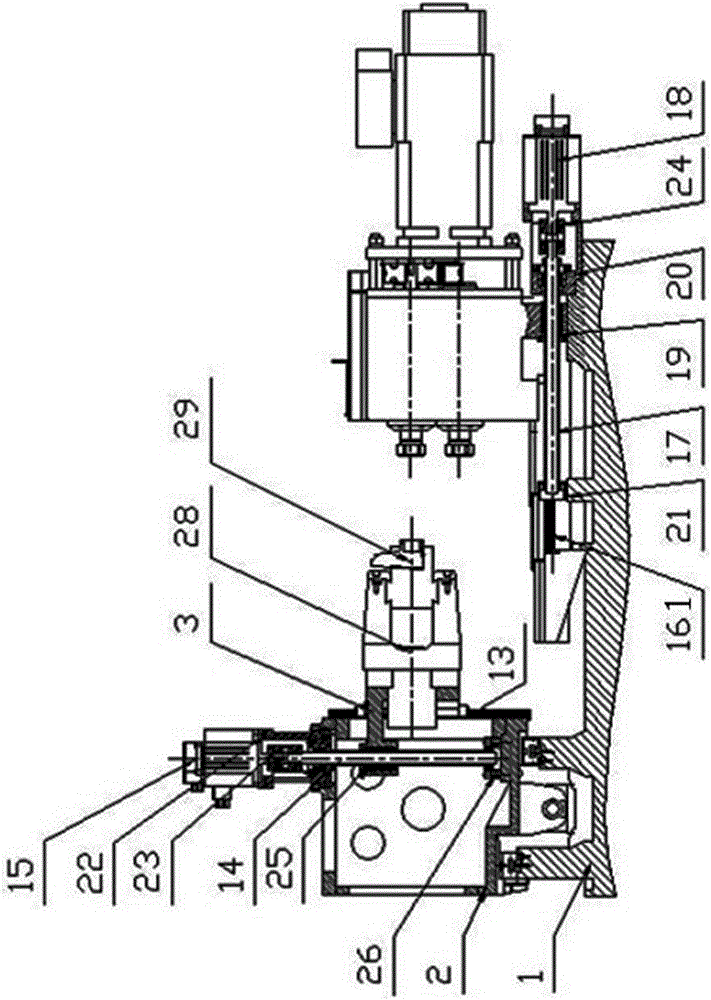

[0013] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment: figure 1 to image 3 Shown is a horizontal CNC five-axis drilling, milling and tapping special machine of the present invention, which is characterized in that it includes a machine base 1, a column 2, a workbench 3, a five-axis spindle box, a spindle 5, a five-axis spindle head 6, X-axis rail slider 9, X-axis ball screw 11, X-axis servo motor 12, Y-axis rail slider 13, Y-axis ball screw 14, Y-axis servo motor 15, Z-axis rail slider 161, Z-axis ball Screw rod 17, Z-axis servo motor 18, spindle servo motor 8, CNC control system, hydraulic system 10, lubrication system, cooling system, chip removal system and fully enclosed cover, the column 2 drives the above-mentioned workbench 3 to make XY coordinates Displacement action; the column 2 and the five-axis spindle head 6 are respectively connected with the X-axis rail slider 9 and the Z-axis rail sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com