Method for designing vehicle on basis of wheel system structure

A system structure and wheel technology, applied in the direction of wheels, vehicle parts, wheels that can support multiple tires, etc., can solve the problems of driving wheel fatigue, hindering the rational development of human society, increasing the driving force of vehicles, etc., and achieve the goal of simplifying the configuration of the transmission system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

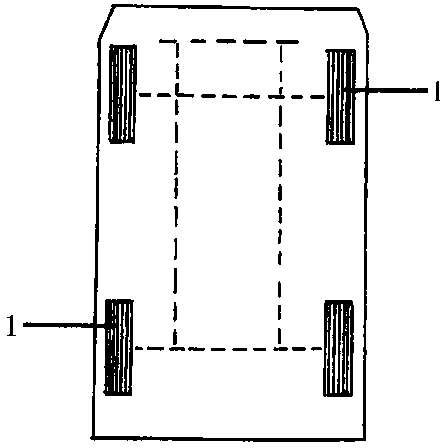

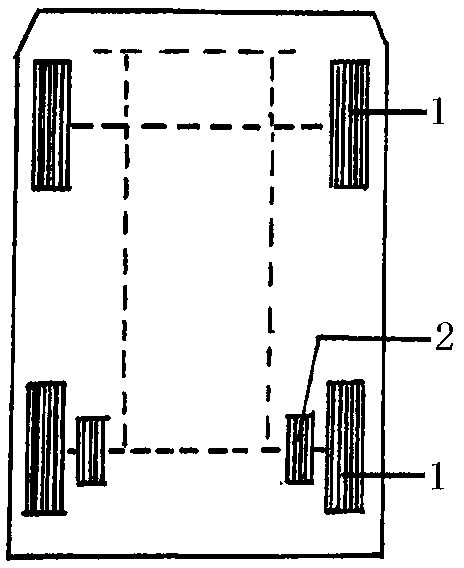

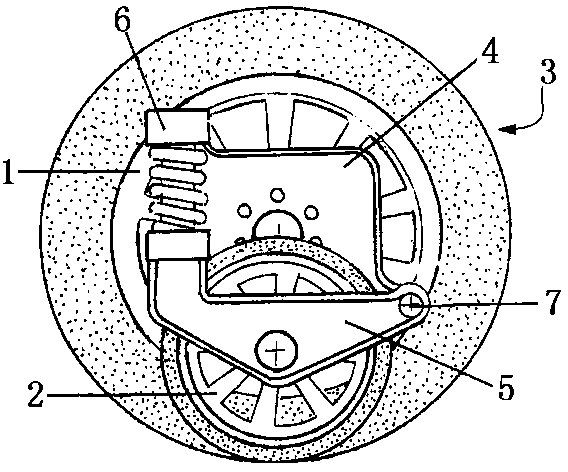

[0044] A method for designing a vehicle based on the wheel system structure. The vehicle wheel system is composed of several load wheels installed on the frame to form a functional structure with load capacity, vehicle stability and mobility, and the load wheel is a large radius Orientation, thus, the vehicle power setting and other conditions must meet the requirements of the structure; the frame is also equipped with a driving wheel, which is a functional supplement of the load wheel system structure, and its driving force requirements are determined by the load wheel vehicle. The power condition is determined, and the driving wheel is oriented with a small radius, thus, the reasonable configuration of the vehicle power and transmission system is determined. This configuration condition is not demanding, and it is a high-efficiency configuration; Traffic conditions, adopt the method of composite wheels composed of load wheels and drive wheels. The following takes a tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com