A method and device for preparing sodium bicarbonate by acid gas

A sodium bicarbonate and acid gas technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low purity of sulfur products, expensive desulfurization catalysts, failure to realize continuous production normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

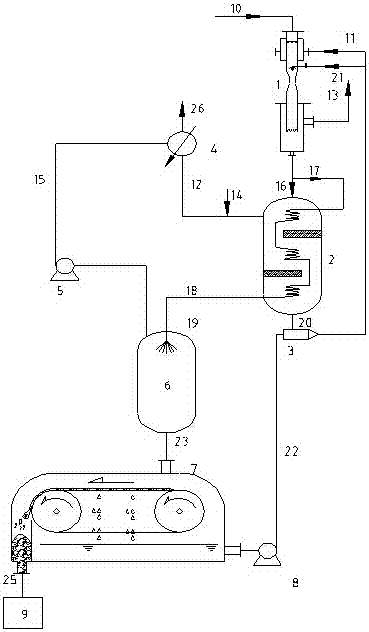

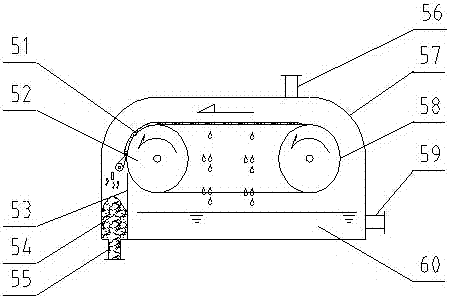

[0087] use as figure 1 The shown method and device react with acid gas as raw material. CO in acid gas 2 The volume fraction is 7%, H 2 The volume fraction of S is 92%, and the volume fraction of hydrocarbons is 1%.

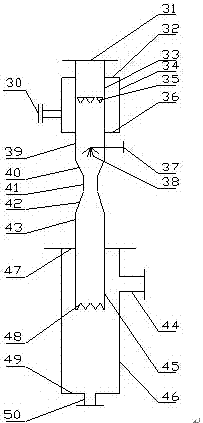

[0088] In embodiment 1, described absorption reactor adopts such as figure 2 Structure. In Example 1, the 22nd stream obtained from the absorption reactor accounts for 20% of the total volume flow of the 2nd stream. The temperature range of the sodium hydrosulfide solution heated by the heating tank is 90°C~99°C, and the mass concentration of the sodium hydroxide solution prepared by using the process generated water is 38%. The 42nd stream accounts for 20% of the total volume flow of the 4th stream. The liquid-gas ratio of absorption liquid and acid gas in the absorption reactor is 5L / m 3 . The reaction temperature was controlled between 80°C and 85°C, and the reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com