Alkyd resin for low-cost mixed paint and preparation method thereof

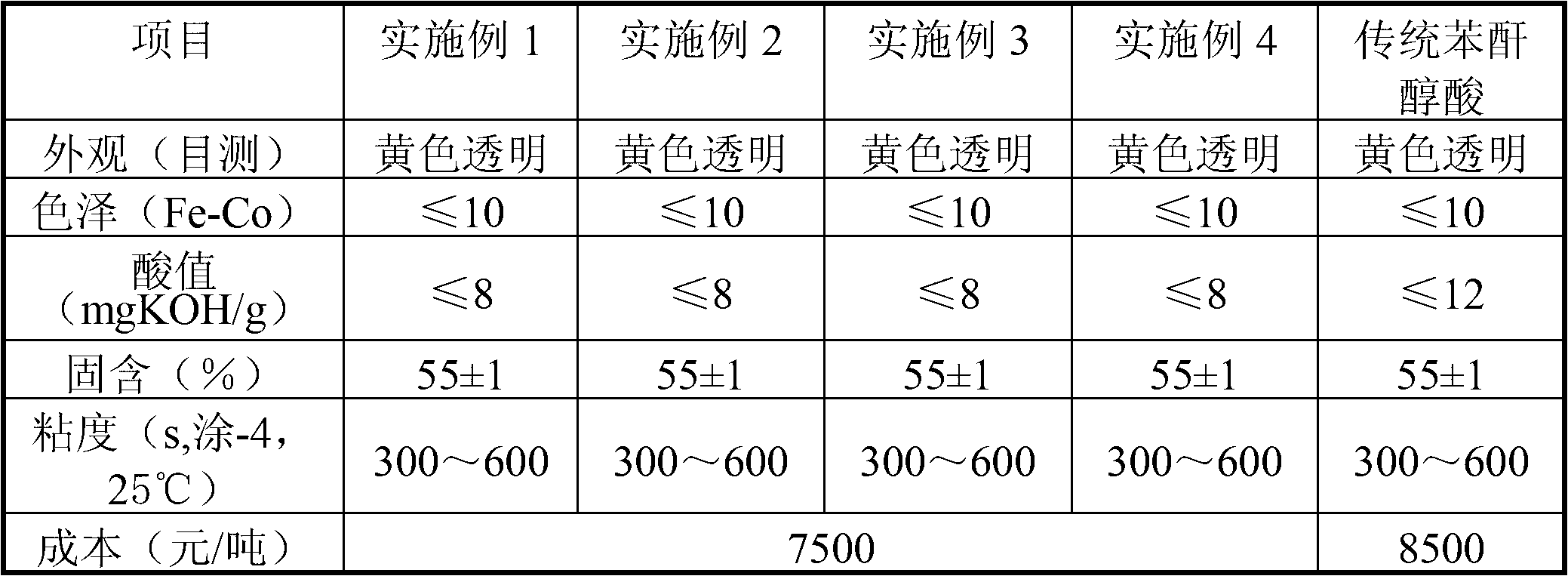

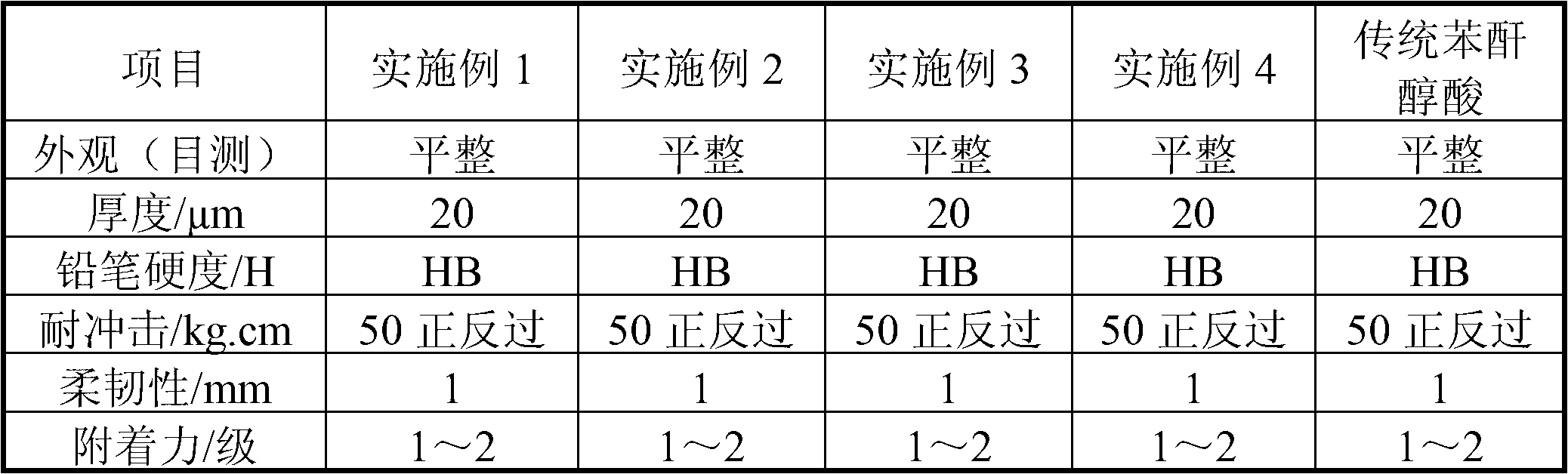

An alkyd resin, low-cost technology, applied in the field of alkyd resin for low-cost blending paint and its preparation, can solve the problems of resin opacity, complex production process control, deep resin color, etc., achieve consistent performance, reduce cost, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

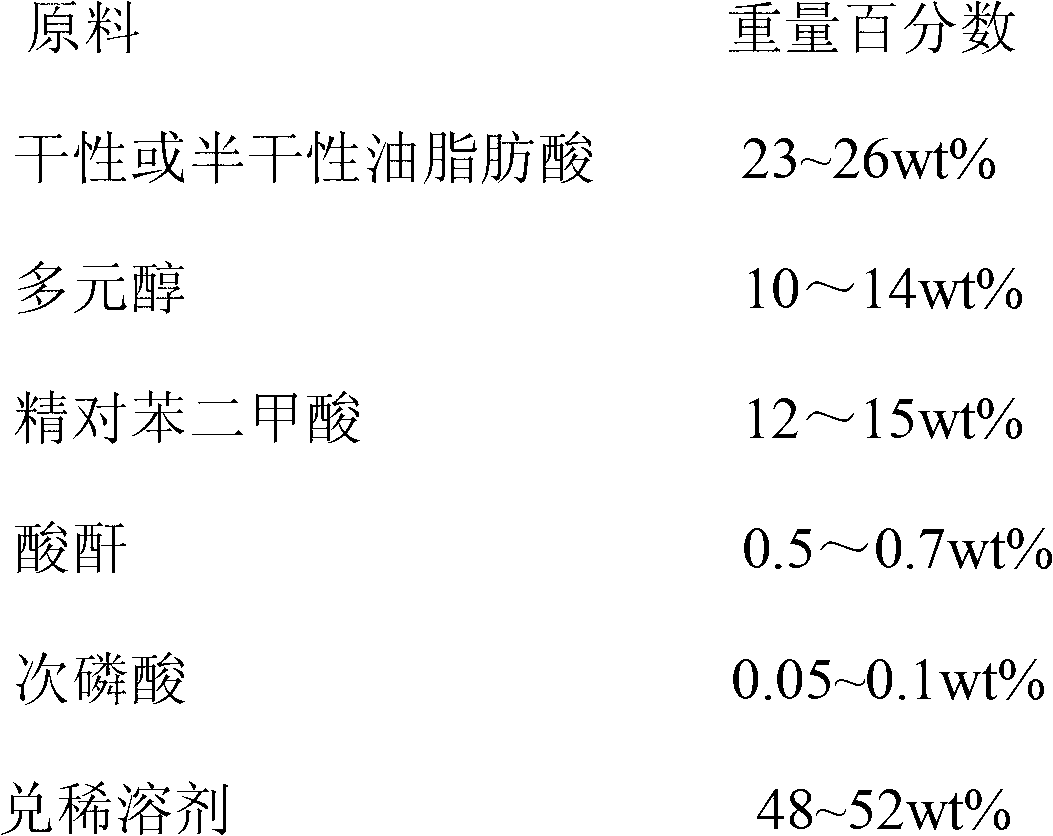

Method used

Image

Examples

Embodiment 1

[0013] Put 23.1% soybean oil acid, 12.45% glycerin, 14.4% purified terephthalic acid, and 0.05% hypophosphorous acid into the reaction kettle, and raise the temperature at 225°C to 235°C for esterification until the resin is clear and transparent, and the acid value is below 8mgKOH / g , Viscosity 15~25s / 25℃, Grignard viscosity, then cool to 180℃, add 0.5% maleic anhydride, continue the reaction until the resin acid value is below 6mgKOH / g, viscosity 20~22s / 25℃, Grignard viscosity, Finally, cool and add 49.5% No. 200 solvent oil, and then dilute and discharge.

Embodiment 2

[0015] Put 24.65% soy oil, 10.88% trimethylolpropane, 13.81% purified terephthalic acid, and 0.05% hypophosphorous acid into the reaction kettle, and raise the temperature at 225°C to 235°C for esterification until the resin is clear and transparent, and the acid value Below 8mgKOH / g, viscosity 15~25s / 25℃, Grignard viscosity, then cool to 180℃, add 0.55% maleic anhydride, continue the reaction until the resin acid value is below 6mgKOH / g, viscosity 20~22s / 25℃, Grignard Until the viscosity is reached, finally cool and add 50.06% hydrogenated carbon nine solvent, dilute and discharge.

Embodiment 3

[0017] Put 25.48% linseed oil fatty acid, 13.55% glycerin, 12.1% purified terephthalic acid, and 0.05% hypophosphorous acid into the reaction kettle, and raise the temperature at 225℃~235℃ for esterification until the resin is clear and transparent, and the acid value is 8mgKOH / g Below, the viscosity is 15-25s / 25°C, Grignard viscosity, then cool to 180°C, add 0.65% phthalic anhydride, and continue the reaction until the resin acid value is below 6mgKOH / g, the viscosity is 20-22s / 25°C, Grignard viscosity, Finally, cool and add 48.17% No. 200 solvent oil, and then dilute and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com