Method for preparing alkylate oil by catalysis of gallium chloride acid ion solution

A technology of ionic liquid and alkylation reaction, applied in chemical instruments and methods, physical/chemical process catalysts, pressure vessels used in chemical processes, etc., can solve the problems of high energy consumption, high pollution, instability, etc., and achieve acid Low consumption, low corrosion, and less by-products

Inactive Publication Date: 2012-10-03

INST OF PROCESS ENG CHINESE ACAD OF SCI

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the problems of high pollution and high energy consumption in catalytic alkylation using concentrated sulfuric acid and HF acid as catalysts, and the chloroaluminate ionic liquid is unstable to water and air, the present invention proposes to synthesize a water- and air-stable Alkylation catalyst and preparation method based on chlorogallate ionic liquid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

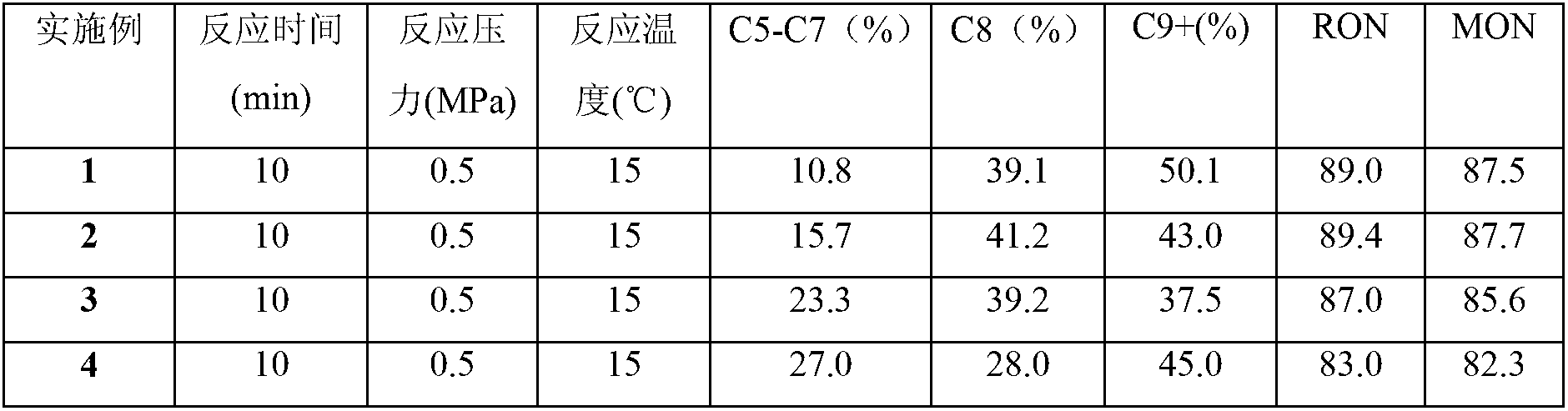

Embodiment 1

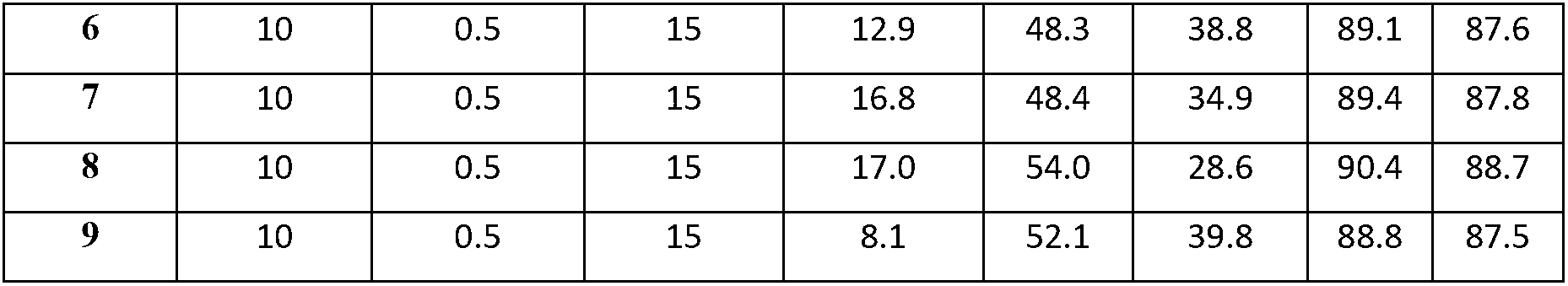

Embodiment 2-4

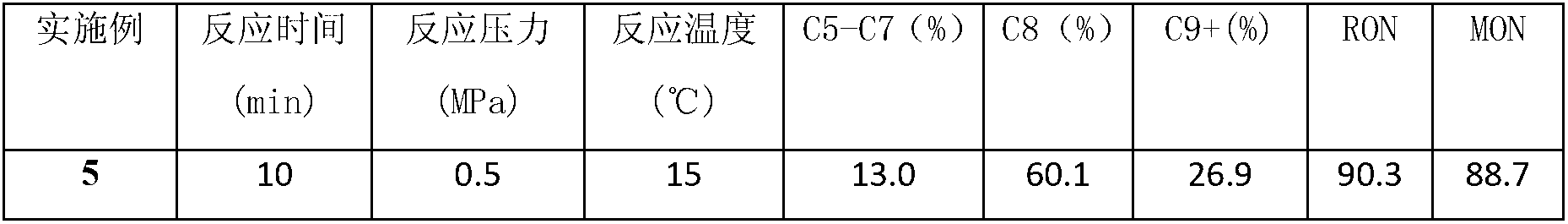

Embodiment 5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for preparing alkylate oil by catalyzing iso-butane and butylenes preparation by a modified gallium chloride acid ion solution in the field of petrochemical industries. The catalyst has higher activity, selectivity and stability in the alkylation process, so that the alkylate oil prepared by the catalyst is characterized in that the quality and the yield are good and high, the catalyst and the alkylation product are easy to separate, the operation is simple and convenient, the corrosion is small, few side product is generated, and little environment pollution is caused.

Description

Technical field: [0001] The invention belongs to the field of petrochemical industry, and mainly relates to a preparation method of an ionic liquid alkylation catalyst, specifically refers to a method for producing high-octane gasoline by using trifluoroethanol or metal chloride-modified chlorogallate ionic liquid as a catalyst . Background technique: [0002] The strong acid-catalyzed C4 alkylation process began in the 1930s and is an important process for the production of clean gasoline in the petrochemical field. It has become an ideal gasoline blending component and is known as the "golden liquid" in the oil refining industry. [0003] At present, the industrial production of alkylation processes mainly includes sulfuric acid and hydrofluoric acid processes. The process technology is relatively mature, but the two processes have high energy consumption and large pollution, and there are many hidden dangers, which limit their wide application. The sulfuric acid alkylat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G50/00B01J3/04B01J31/26B01J31/30

Inventor 赵国英邢学奇李海方张海涛

Owner INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com