Extraction method of dogwood kernel oil

A technology of cornel seed and extraction method, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of not providing extraction equipment and process procedures, and large equipment investment, and achieve low cost and equipment investment Less, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

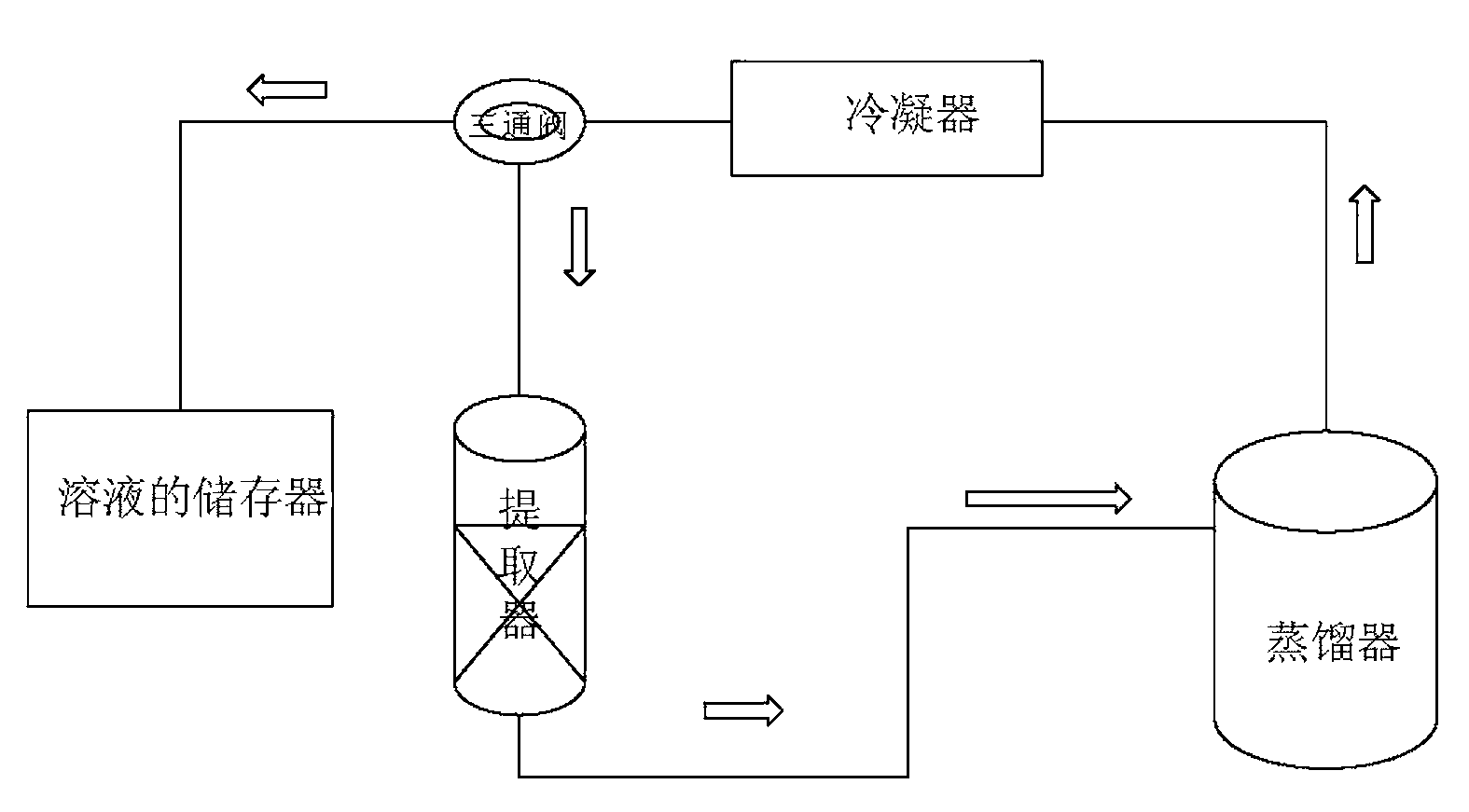

[0014] Crush the dried Cornus officinalis core, pass through a 40-mesh sieve to get coarse powder, take 1000g of coarse powder and add it to the extractor, the lower outlet of the extractor is connected to the upper inlet of the distiller through a siphon, and the height of the coarse powder in the extractor is lower than Or equal to the height of the siphon, inject 800ml of petroleum ether with a boiling point of 60-90°C into the extractor, soak the coarse powder, then add 300ml of petroleum ether with a boiling point of 60-90°C into the distiller, heat to boiling, and maintain In the boiling state, the distiller is connected to the condenser, and the condenser is respectively connected to the extractor and the solvent storage through a three-way valve. The steam is condensed into a liquid state by the condenser and then sprayed into the extractor to percolate the coarse powder. , when the liquid level in the extractor is higher than the siphon tube, the liquid in the extracto...

Embodiment 2

[0016] Pulverize the dried Cornus officinalis core, pass through a 50-mesh sieve to get coarse powder, get 2000g of coarse powder and add it to the extractor, the lower outlet of the extractor is connected to the upper inlet of the distiller through a siphon, and the height of the coarse powder in the extractor is lower than Or equal to the height of the siphon, inject 1650ml of petroleum ether with a boiling point of 60-90°C into the extractor, soak the coarse powder, then add 700ml of petroleum ether with a boiling point of 60-90°C into the distiller, heat to boiling, and maintain In the boiling state, the distiller is connected to the condenser, and the condenser is respectively connected to the extractor and the solvent storage through a three-way valve. The steam is condensed into a liquid state by the condenser and then sprayed into the extractor to percolate the coarse powder. , when the liquid level in the extractor is higher than the siphon tube, the liquid in the extr...

Embodiment 3

[0018]Pulverize the dried Cornus officinalis core, pass through a 30-mesh sieve to get coarse powder, take 3000g of coarse powder and add it to the extractor, the lower outlet of the extractor is connected to the upper inlet of the distiller through a siphon, and the height of the coarse powder in the extractor is lower than Or equal to the height of the siphon, inject 2700ml of petroleum ether with a boiling point of 60-90°C into the extractor, soak the coarse powder, then add 1200ml of petroleum ether with a boiling point of 60-90°C into the distiller, heat to boiling, and maintain In the boiling state, the distiller is connected to the condenser, and the condenser is respectively connected to the extractor and the solvent storage through a three-way valve. The steam is condensed into a liquid state by the condenser and then sprayed into the extractor to percolate the coarse powder. , when the liquid level in the extractor is higher than the siphon tube, the liquid in the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com