Non hardened and tempered state hot-rolled steel strip with yield strength higher than 900MPa and preparation method thereof

A technology of yield strength and hot-rolled strip steel, applied in the field of metallurgy, can solve the problems of high alloy cost and high cost of quenching and tempering process, achieve high mechanical properties, improve work hardening ability, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

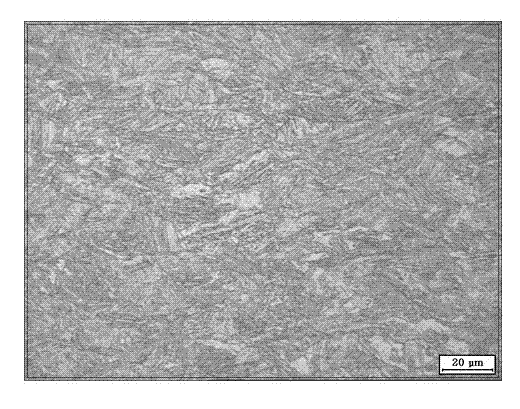

Image

Examples

Embodiment 1

[0024] Molten steel is smelted in a 150-ton converter according to the set composition, and continuously cast into a billet. The composition is C0.06%, Si 0.20%, Mn 1.20%, Nb 0.02%, V 0.04%, Ti0.04% by weight , Cr0.8%, Mo0.30%, B0.001%, P<0.012%, S<0.01%, the balance is iron Fe, and the thickness of the slab is 220mm.

[0025] The cast slab was heated to 1250°C for rough rolling, the rough rolling process was 5 passes, the rough rolling start temperature was 1170°C, and the rough rolling finish rolling temperature was 1070°C to obtain an intermediate slab with a thickness of 38mm.

[0026] The intermediate billet is finished rolling, the finishing rolling process is 7 passes, the starting temperature of the finishing rolling is 980°C, the temperature of the second rolling is 950°C, the temperature of the third rolling is 930°C, the temperature of the fourth rolling is 890°C, and the temperature of the fifth rolling is 850°C ℃, the sixth rolling temperature is 820 ℃, the finish...

Embodiment 2

[0029] The preparation method and composition of the slab are the same as in Example 1, and the thickness of the slab is 250 mm.

[0030] The rough rolling process was the same as in Example 1, and an intermediate billet with a thickness of 58 mm was obtained.

[0031]The intermediate billet is finished rolling, the finishing rolling process is 6 passes, the starting temperature of the finishing rolling is 960°C, the temperature of the second rolling is 940°C, the temperature of the third rolling is 920°C, the temperature of the fourth rolling is 900°C, and the temperature of the fifth rolling is 860°C ℃, the final rolling temperature is 840 ℃, the reduction of each pass of finishing rolling is controlled at 15~40%, and the strip thickness after finishing rolling is 12mm.

[0032] After finishing rolling, it is water-cooled to 450°C at a speed of 35°C / s, coiled by a coiler, and then tempered off-line. The performance test results are: yield strength 930MPa, tensile strength 9...

Embodiment 3

[0034] The preparation method and composition of the slab are the same as in Example 1, and the thickness of the slab is 240mm.

[0035] The rough rolling process was the same as in Example 1, and an intermediate billet with a thickness of 45 mm was obtained.

[0036] The intermediate billet is finished rolling, the finishing rolling process is 5 passes, the finishing rolling temperature is 1000°C, the second rolling temperature is 980°C, the third rolling temperature is 920°C, the fourth rolling temperature is 900°C, and the final rolling temperature is 880°C ℃, the reduction in each pass of finish rolling is controlled at 15~40%, and the strip thickness after finish rolling is 6mm.

[0037] After finishing rolling, it is water-cooled to 200°C at a speed of 15°C / s, coiled by a coiler, and then tempered offline. The offline tempering temperature is 600°C, and the tempering time is 2 hours. The mechanical performance test results are: yield strength 940MPa, tensile strength 98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com