Auxiliary device for preparing thin film electrode

An auxiliary device and thin-film electrode technology, which is applied in the field of auxiliary devices for preparing thin-film electrodes, can solve problems such as loose contact and uneven thin-film electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

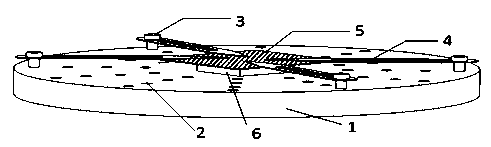

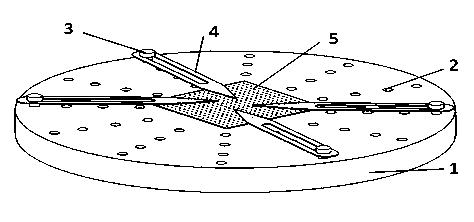

[0011] Examples of auxiliary devices for preparing thin-film electrodes of the present invention: such as figure 1 , figure 2 As shown, the chassis 1 of the auxiliary device is a circular structure with a certain thickness, and the mask plate 5 and the substrate 6 for preparing the thin film electrodes are stacked up and down and placed at the center of the circle on the upper end face of the chassis 1. The placement mask of the chassis 1 The area of the plate 5 and the substrate 6 is the support end surface, the center of the base plate 1 is the center of the support end surface, and a pressing mechanism is also installed on the base plate 1 . The pressing mechanism includes four pressing clips 4 and four control screws 3. One end of the pressing clip 4 is placed on the chassis 1, and the other end is press-fitted on the mask plate 5. The four control screws 3 are one by one. Correspondingly pass through the four tableting clips 4 and finally screw into the chassis 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com