Central adjusting device of double-needle-bar tricot machine

A double-needle-bed warp knitting machine and adjusting device technology are applied in the directions of warp knitting, knitting, textiles and paper making, which can solve the problems of cumbersome work operation, high labor intensity and low operation efficiency, and achieve low labor intensity and low operation efficiency. The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

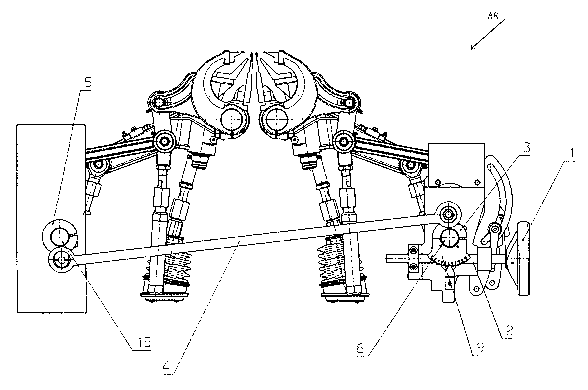

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, a central adjustment device of a double-needle bed warp knitting machine, including an adjustment hand wheel 1, a special-shaped shaft 2, a special-shaped tight ring 3, a connecting rod 4, a tight ring 5, a pendulum shaft 6 and a dial 9 , the adjustment handwheel 1 is connected with the special-shaped shaft 2, the special-shaped tight ring 3 is arranged on the special-shaped shaft 2, one end of the connecting rod 4 is connected with the special-shaped tight ring 3, and the other end is connected with the special-shaped tight ring 5, and the special-shaped tight ring 3 is connected with the pendulum shaft-6 Connection, tight ring 5 is connected with pendulum shaft 2 15, and a dial 9 is arranged below the special-shaped tight ring 3, which improves the adjustment accuracy, and the user can easily know the adjusted value through the dial.

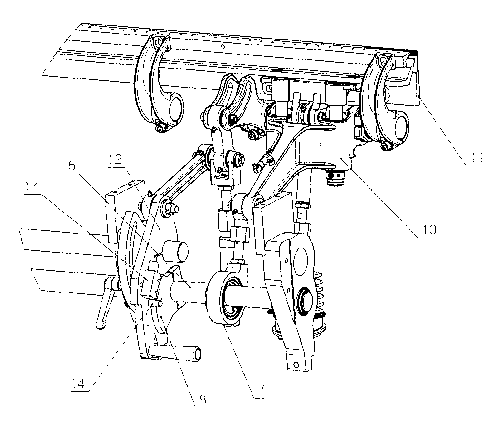

[0015] Such as figure 2 yes figure 1 A Schematic vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com