Method for reusing waste cigarette-used cellulose acetate fibers

A technology for diacetate fibers and cigarettes, applied in the direction of synthetic cellulose fibers, etc., can solve the problems of affecting application, fiber damage, strength reduction, etc., and achieve the effects of simple operation, small investment scale, and large economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

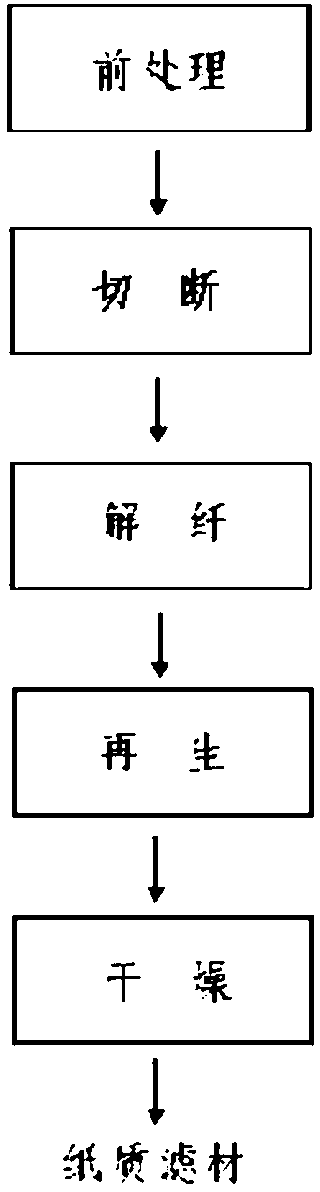

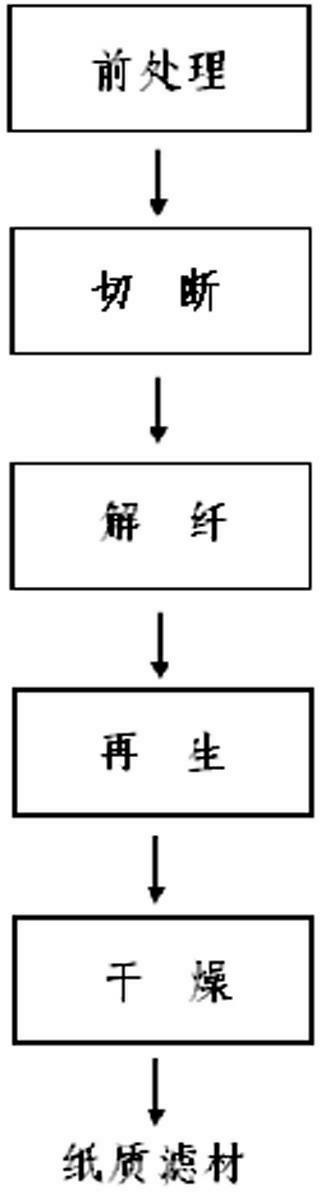

Image

Examples

Embodiment 1

[0026] Remove paper and other sundries in 500kg of waste cellulose diacetate tow, cut it to 2mm with a fiber cutter, and then open it with an opener to obtain 1mm short cellulose diacetate fibers, which are added at a dosage of 100% Into the papermaking raw materials, the waste diacetate cellulose tow regenerated filter base material with a weight of 36g / ㎡ was produced by the wet paper papermaking process, and it was made into a 25mm tip stick for cigarettes, and it was mixed with ordinary diacetate cellulose tow The filtering efficiency of the tar is increased by 10% compared with the same period of the filter rod.

Embodiment 2

[0028] Remove paper and other sundries in 800kg of waste cellulose diacetate tow, cut them to 5mm with a fiber cutter, and then open them with an opener to obtain 4mm cellulose diacetate short fibers, which are added in an amount of 10% Into the papermaking raw materials, the waste diacetate cellulose tow regenerated filter base material with a weight of 40g / ㎡ was produced by wet papermaking process, and it was made into a 25mm tip stick for cigarettes, and it was mixed with ordinary diacetate cellulose tow The filtering efficiency of the tar is increased by 30% compared with the same period of the filter rod.

Embodiment 3

[0030] After removing the paper and other sundries in the 1000kg discarded cellulose diacetate tow, cut it to 4mm with a fiber cutter, and then open it with an air flow dispersion device to obtain 3mm cellulose diacetate short fibers, which are added to the Among the raw materials for papermaking, the weight is 50g / m2 produced by dry-laid papermaking process 2 The discarded cellulose diacetate tow regenerated filter base material, and made into a 25mm tip rod for cigarettes, compared with ordinary cellulose diacetate tow filter rods, the filtration efficiency of tar increased by 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com