Engineered cementitious composite (ECC)-reinforced concrete (RC) combination column and novel connection mode thereof

A connection method and combined column technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of limiting the overall performance of the assembled integral structure, difficult to effectively guarantee the quality of concrete pouring, and increasing the difficulty of construction, so as to achieve good construction quality and Seismic performance, simplicity of design and construction, and effect of reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

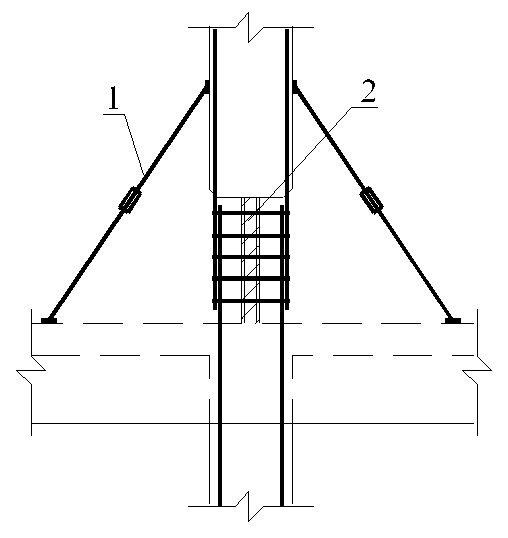

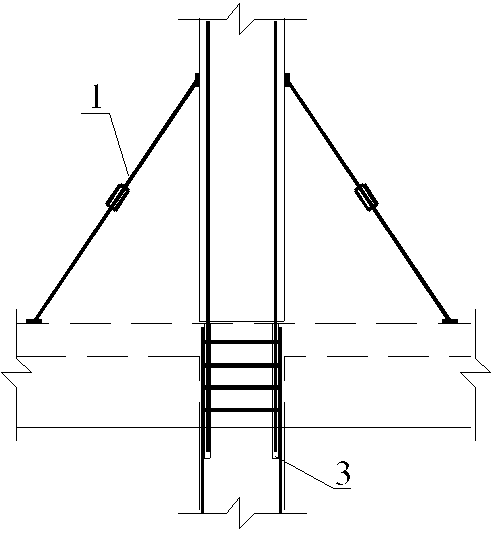

[0019] From figure 1 It can be seen that the existing prefabricated column-shaped steel support connection method adopts the I-beam 2 to bear the self-weight of the upper column, and after the column is in place, the adjustable diagonal brace 1 is used to correct and fix it. figure 2 For the existing prefabricated column, the connection method of reserving holes for inserting ribs is provided, and the reserved holes 3 are set in the lower column, and the longitudinal ribs at the bottom of the upper column are stretched out. When installing, insert the longitudinal reinforcement at the bottom of the upper column into the reserved hole at the top of the lower column to get in place, and use the adjustable diagonal brace 1 to correct and fix it. figure 1 , figure 2 The adjustable diagonal brace 1 can only be removed when the concrete strength of the beam-column joint of the previous layer reaches 10MPa.

[0020] Engineering cementitious composite material (Engineered Cementit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com