Natural gas hydrate exploiting method

A mining method and hydrate technology, applied in the fields of fluid mining, mineral mining, earthwork drilling, etc., can solve the problems of low heat and mass transfer characteristics, low conductivity, low mining efficiency, etc. The effect of large flow conductivity and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the method for exploiting natural gas hydrate by injecting hot water:

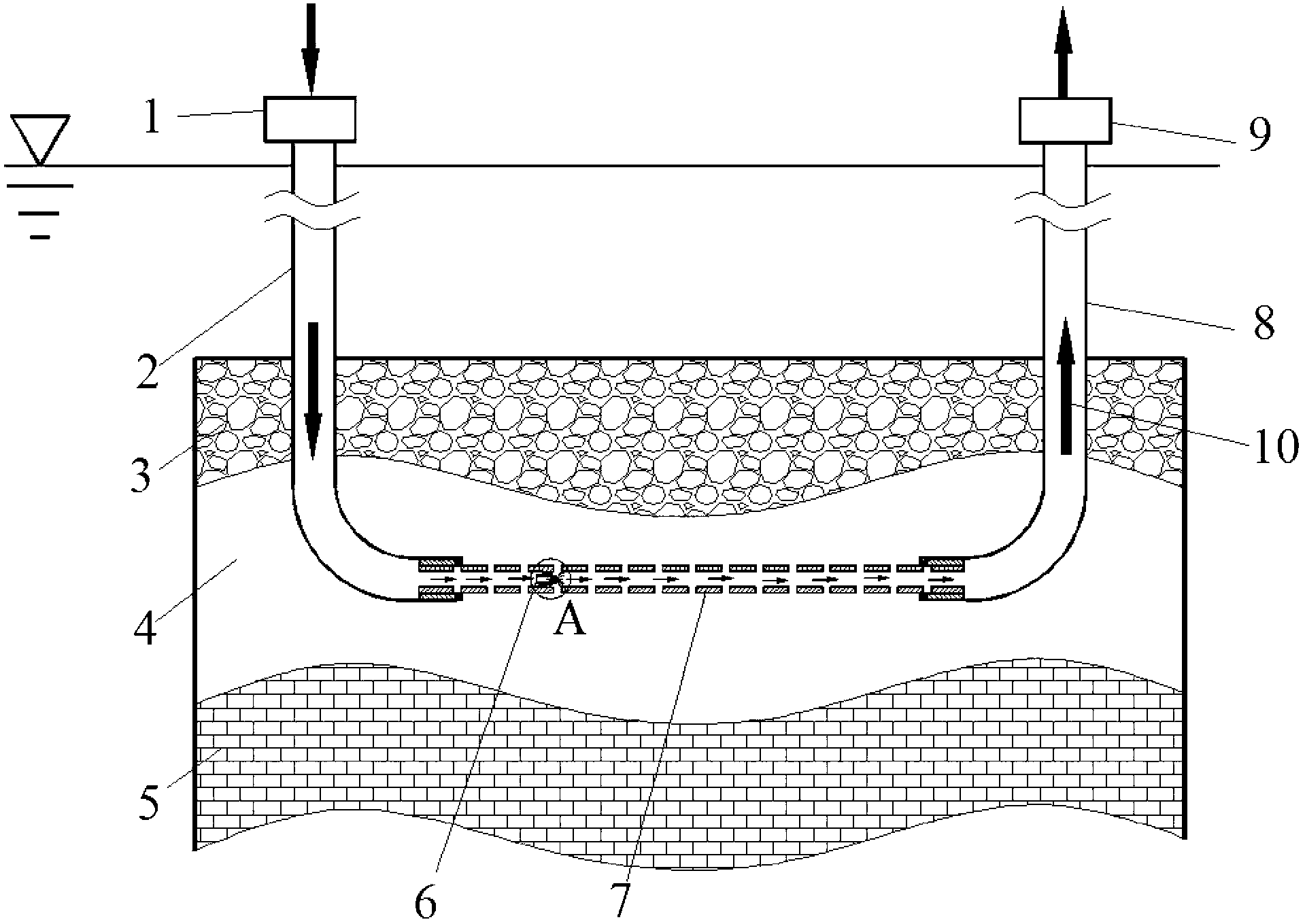

[0024] (1) if figure 1 As shown, a connecting well is drilled in the hydrate reservoir, the length of the horizontal section is 200-500 m, and the screen 7 is used to complete the entire horizontal section.

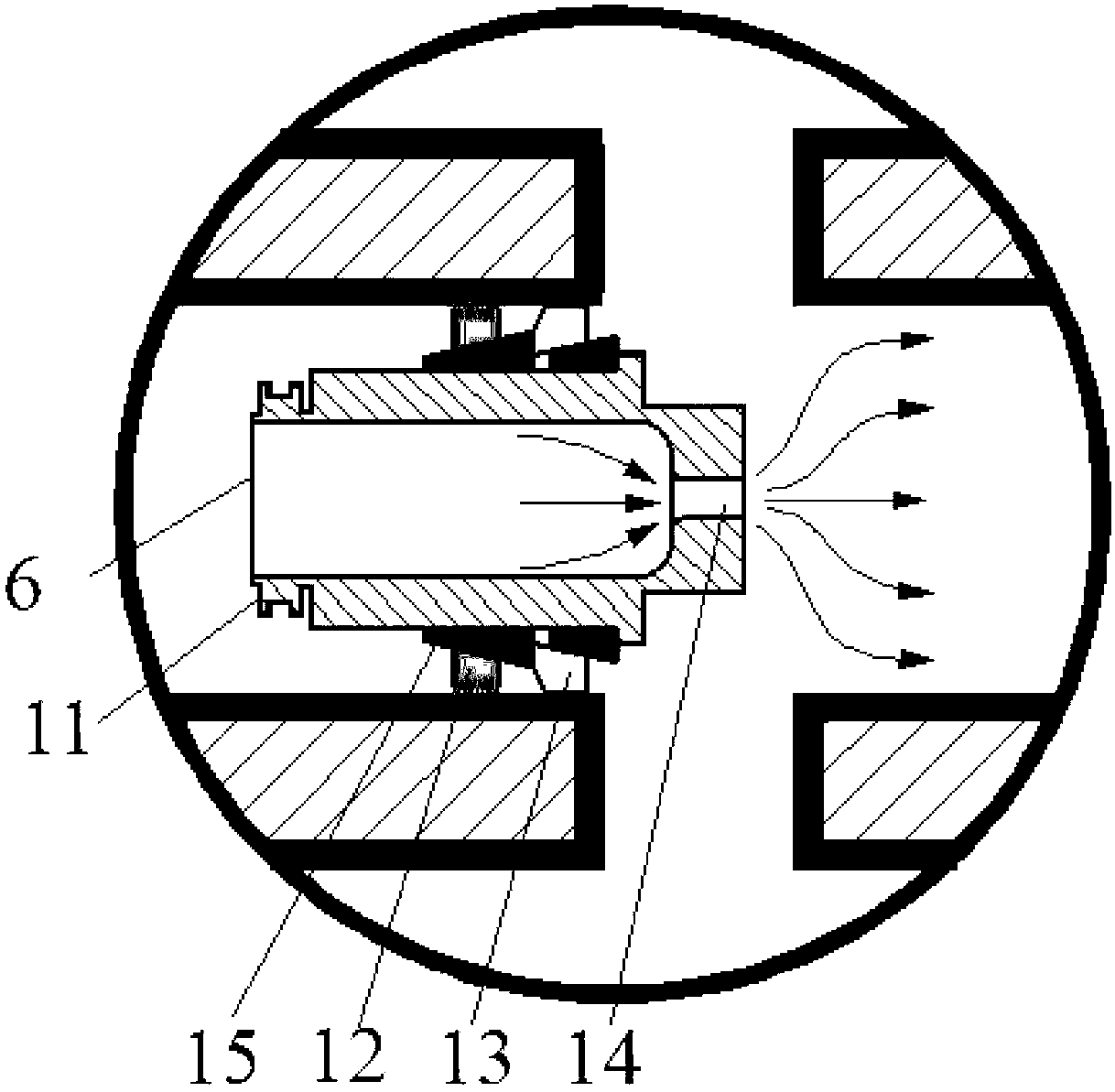

[0025] (2) Insert the throttling device 6 in the screen pipe (such as figure 2 shown), the throttling device 6 is installed at a distance of 1 / 5-2 / 5 from the injection well, and the slips 12 are set to push the wedge-shaped body 15 to move, thereby making the rubber tube 13 seal the throttling device 6 and the screen pipe 7 between the annular spaces.

[0026] (3) 60-300m from injection well 1 3 The hot water at 60-95°C is injected at the injection rate per day, and when it flows through the throttling device 6, a low pressure is generated behind the throttle nozzle 14. Under the double excitation of the low pressure and the injected hot fluid, the hydrate decomposition starts...

Embodiment 2

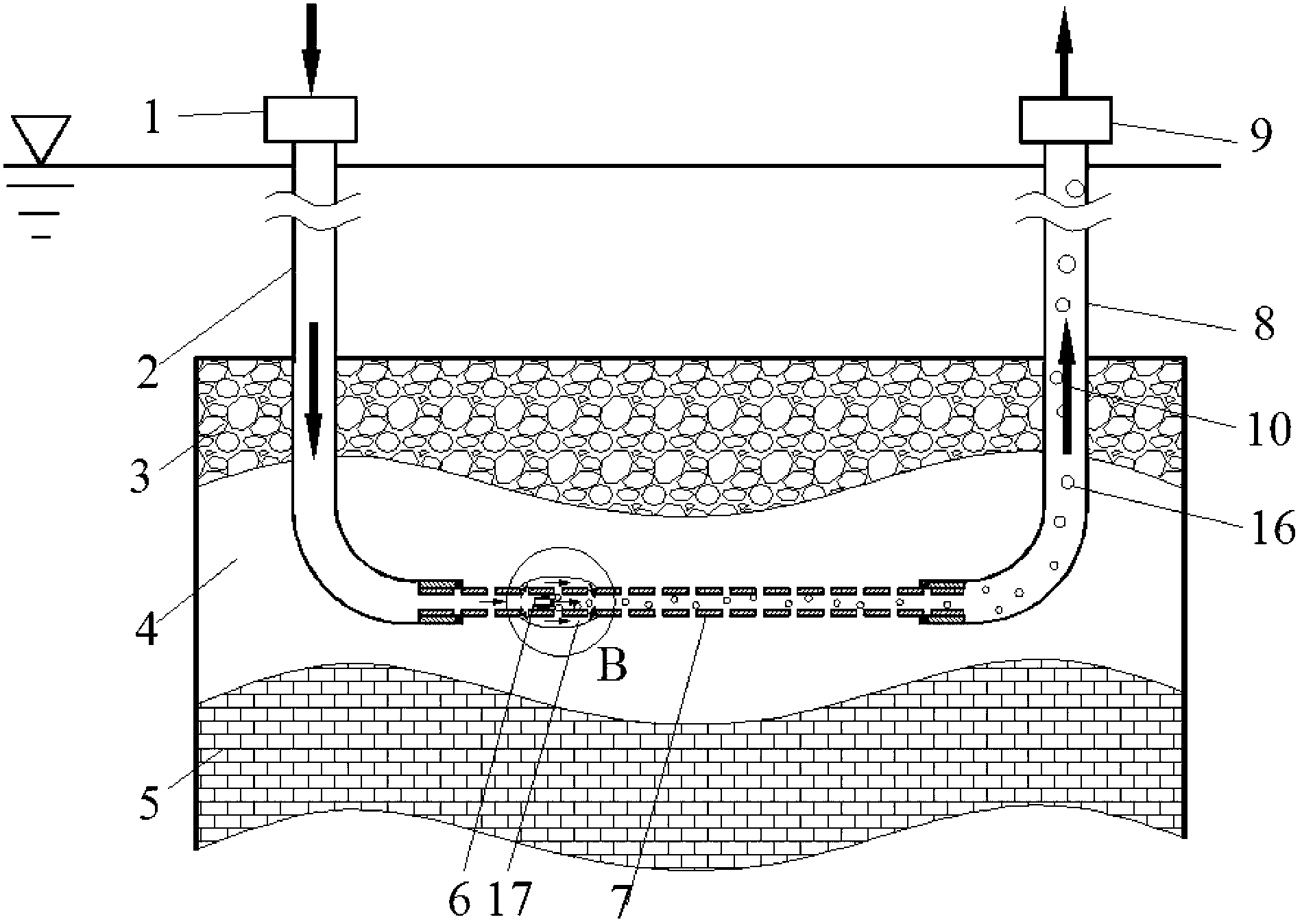

[0029] Example 2, the method of injecting hydrate decomposition accelerator to exploit hydrate:

[0030] (1) if figure 1 As shown, a connecting well is drilled in the hydrate reservoir, the length of the horizontal section is 200-500 m, and the screen 7 is used to complete the entire horizontal section.

[0031] (2) Insert the throttling device 6 into the screen pipe. The throttling device 6 is installed at a distance of 1 / 5-2 / 5 from the injection well, seals the slip 12, and pushes the wedge-shaped body 15 to move, thereby making the rubber tube 13 The annular space between the throttling device 6 and the screen pipe 7 is sealed.

[0032] (3) Inject brine with a mass concentration of 5% to 25% or methanol with a mass concentration of 60% to 80% from the injection well 1, and fill the entire horizontal section. When it flows through the throttle device 6, after the throttle nozzle 14 Low pressure is generated, and hydrate decomposition starts under the double excitation of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com