Impeller-suspended superminiature pump

An ultra-small, impeller technology, applied in the direction of pumps, parts of pumping devices for elastic fluids, pump devices, etc., can solve problems such as application limitations of ultra-small pumps, and achieve good self-regulation performance, smooth flow, good physiological Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

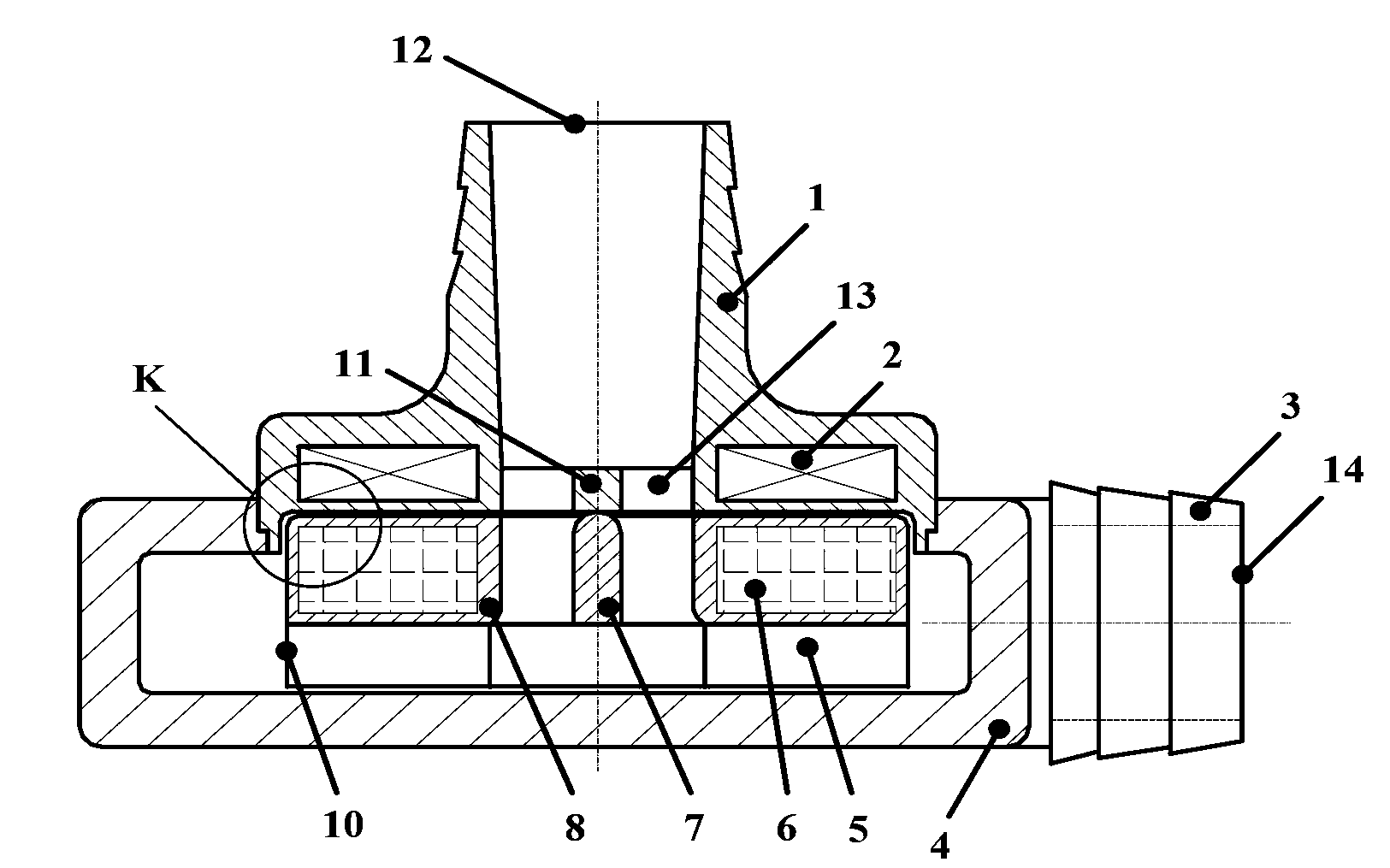

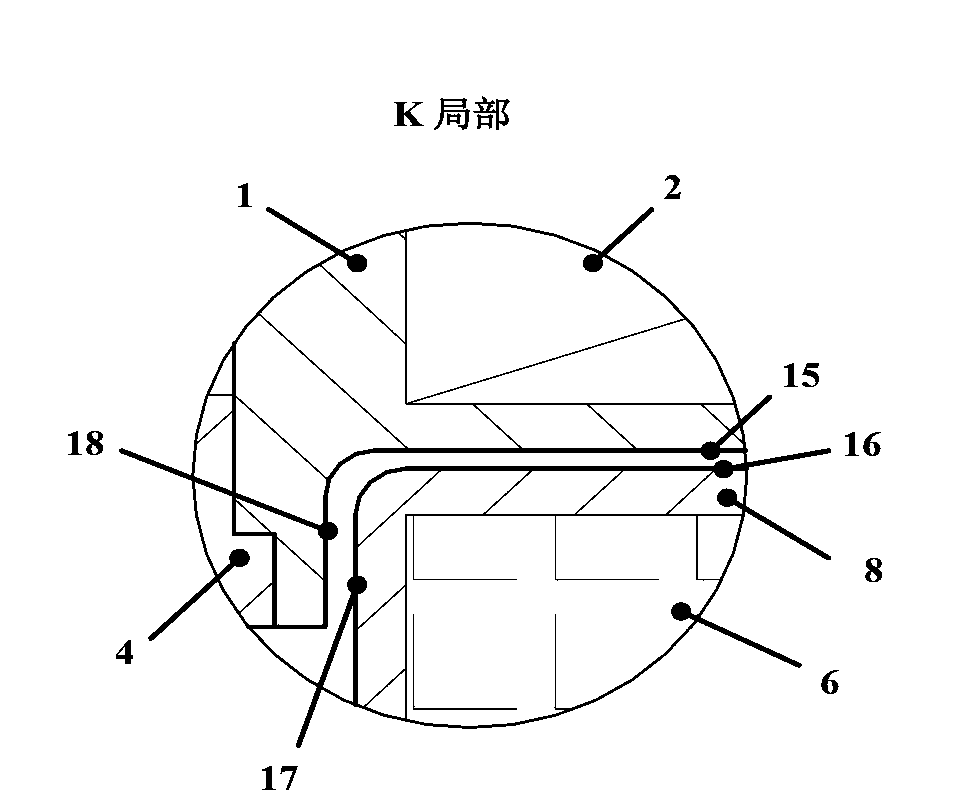

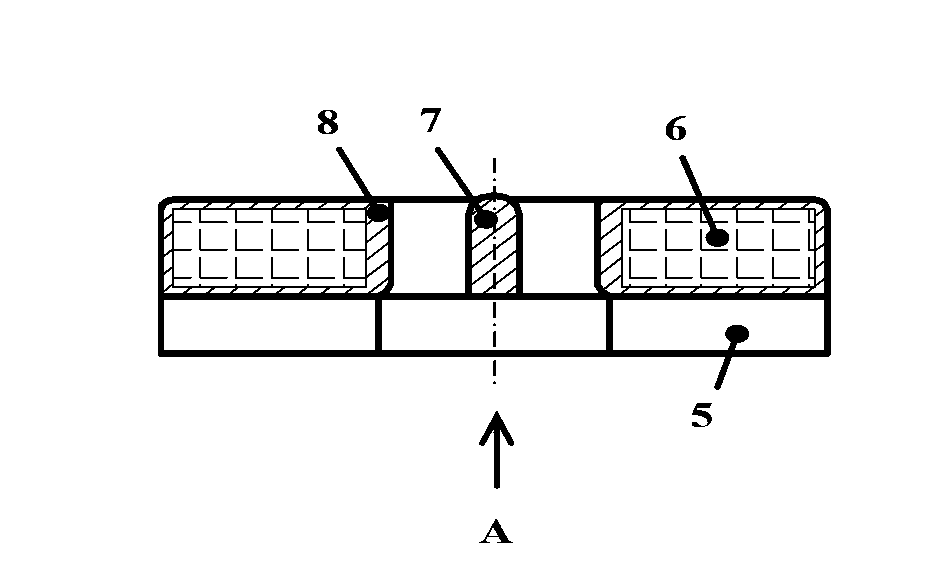

[0015] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] figure 1 It is a cross-sectional view of an ultra-small pump with impeller suspension provided by the present invention. The ultra-small pump includes a pump casing 1 , a motor stator 2 , a pressurized water chamber 4 , a permanent magnet 6 , an impeller 10 , a suction inlet 12 and a pump outlet 14 . The impeller 10 is arranged in the pressure water chamber 4, and the pressure water chamber 4 and the outlet pipe 3 are generally of an integrated structure; the pump casing, the impeller and the pressure water chamber constitute the flow channel of the pump. The impeller 10 includes the impeller front cover 8 and blades 5; the permanent magnet 6 is embedded in the impeller front cover 8, the motor stator 2 is embedded in the pump casing 1, and the permanent magnet and the motor stator are arranged opposite to each other in the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com