Mine axial flow fan diffusion core barrel and optimizing and resistance reducing design method thereof

A technology of axial flow fans and core barrels, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, machines/engines, etc., and can solve problems such as large local resistance loss and disordered flow field at the tail of the diffusion core , to achieve the effect of improving static pressure efficiency, reducing resistance and saving energy, and reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

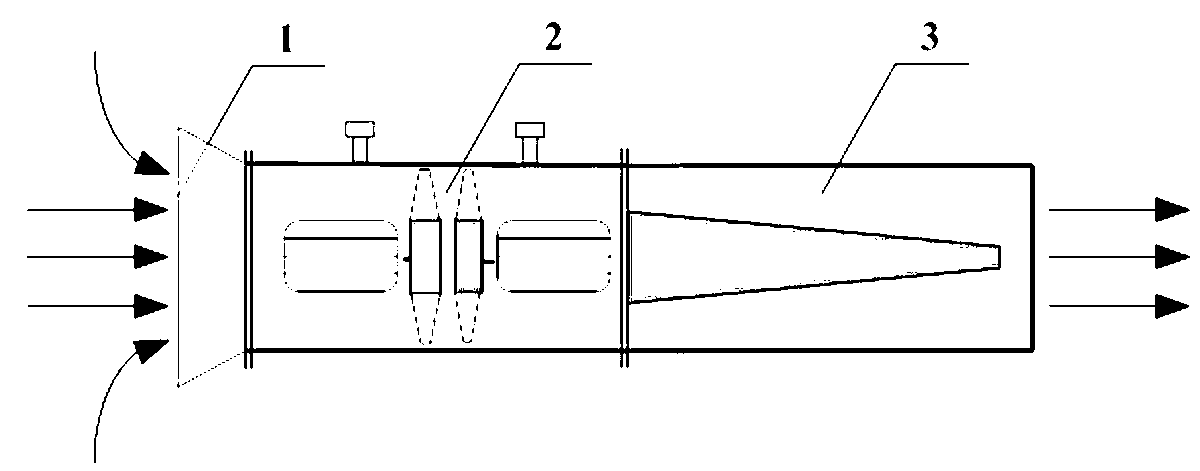

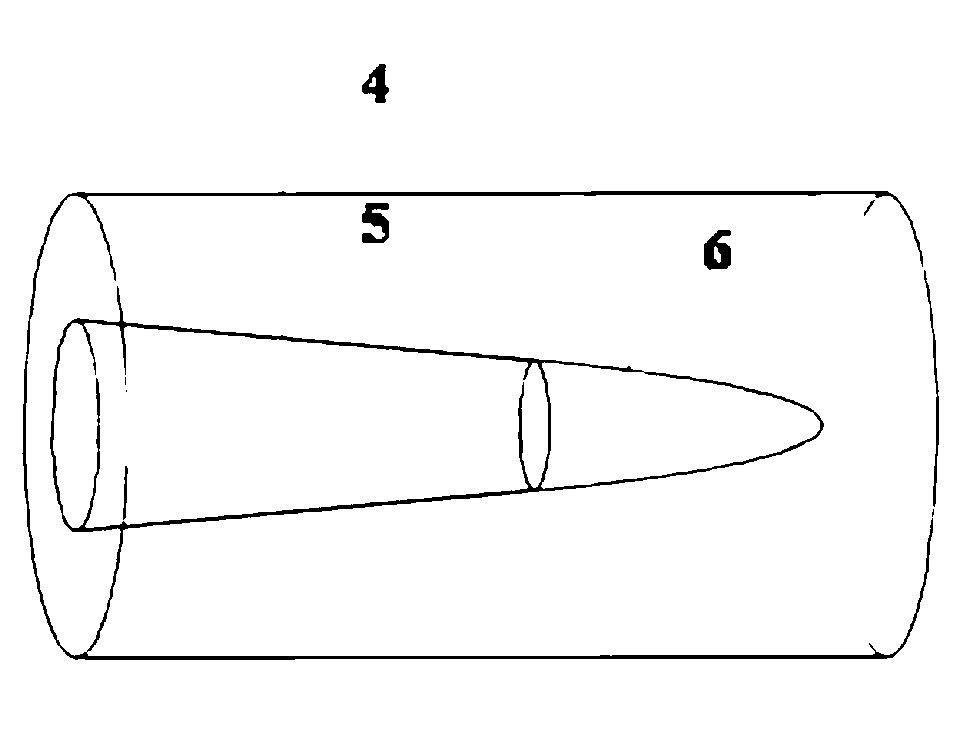

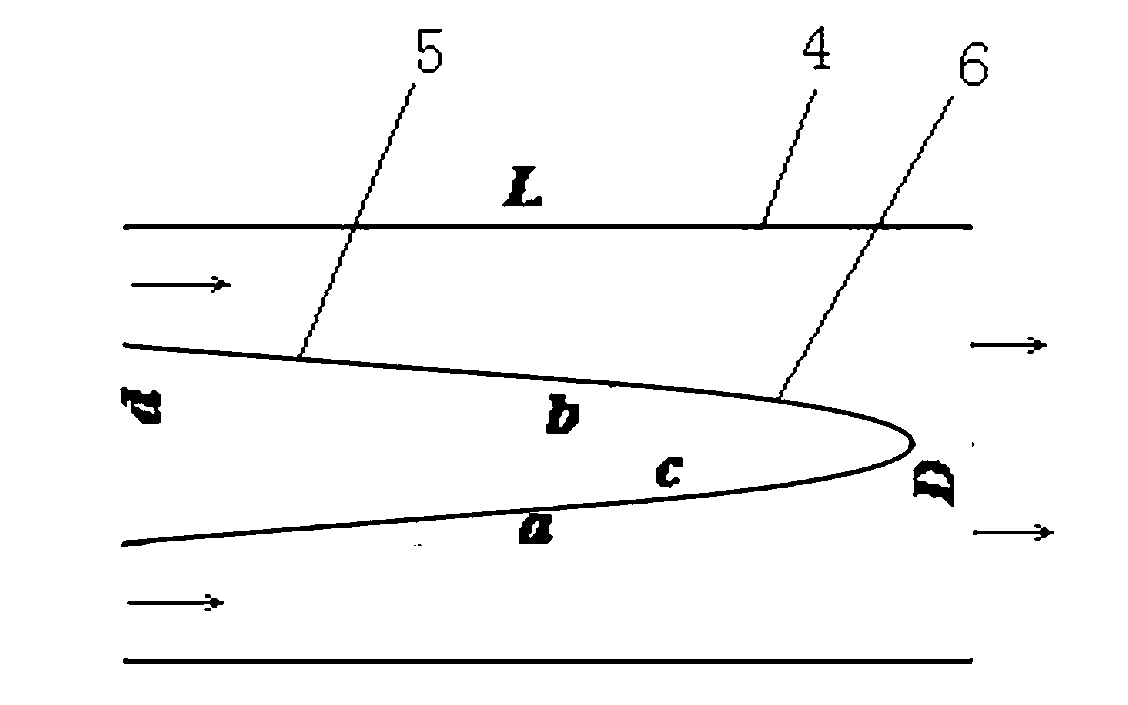

[0023] see figure 1 , is a schematic diagram of the mine axial flow fan and its attachments. from figure 1 It can be seen that 1 is the collector of the mine axial flow main fan, 2 is the fan section of the mine axial flow fan, and 3 is the fan diffuser core barrel section. see figure 2 , is a schematic diagram of the structure of the diffuser core of the present invention, which includes a cylindrical shell 4 and an inner core installed in the shell symmetrically about the axis of the shell. from figure 2 It can be seen in the figure that the inner core is composed of a frustum 5 and a semi-ellipsoid 6. The area of the frustum 5 at the air inlet end, i.e. the left end, is larger than the area at the air outlet end, i.e. the right end. The outlet ends of the airflow are connected to the right end, and the boundary line of the axial se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com