Low-temperature radiation electrothermal film floor heating system

A low-temperature radiation and heating system technology, applied in electric heating systems, heating systems, household heating and other directions, can solve the problems of heating problems that have not been reconciled, long winters, etc., to achieve simple construction, strong controllability, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

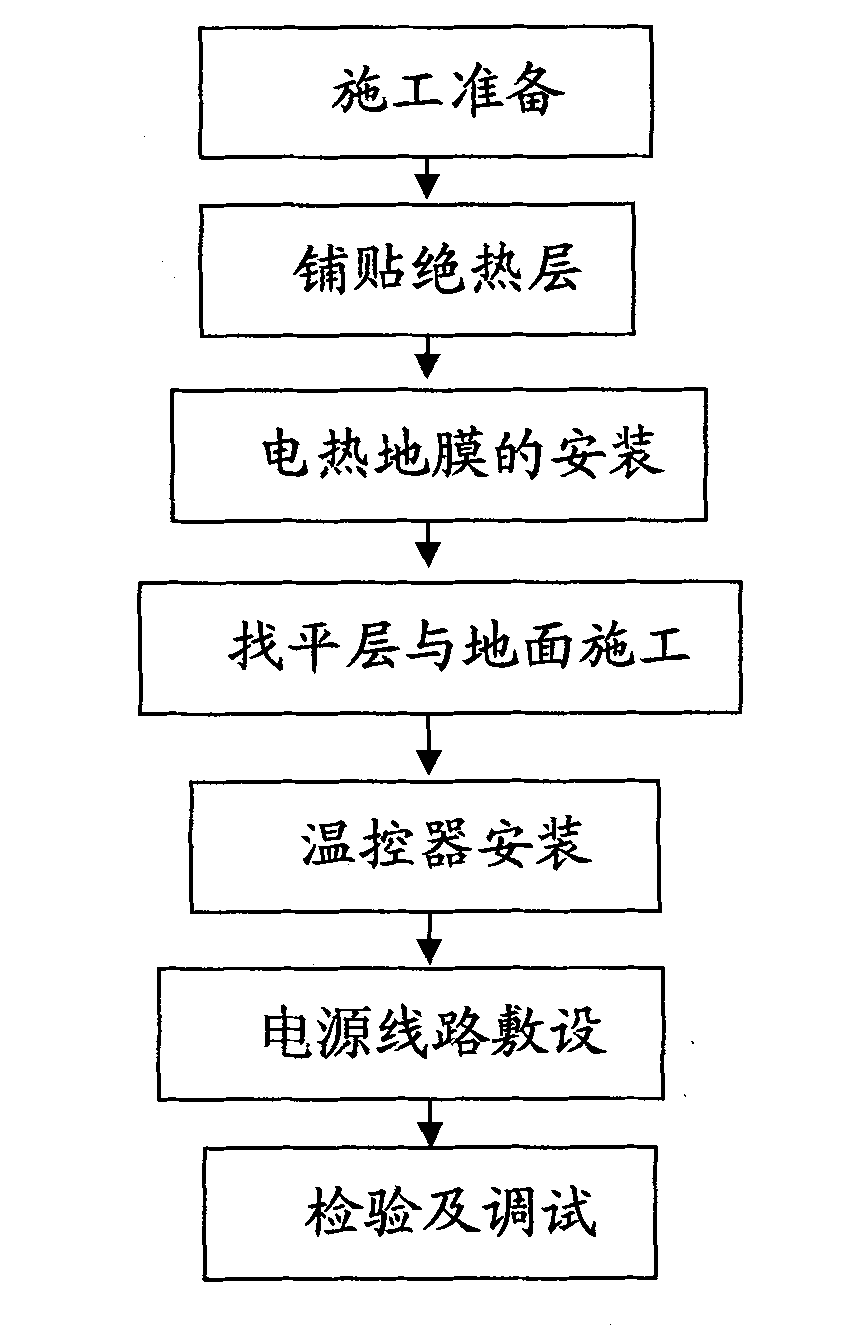

Method used

Image

Examples

Embodiment Construction

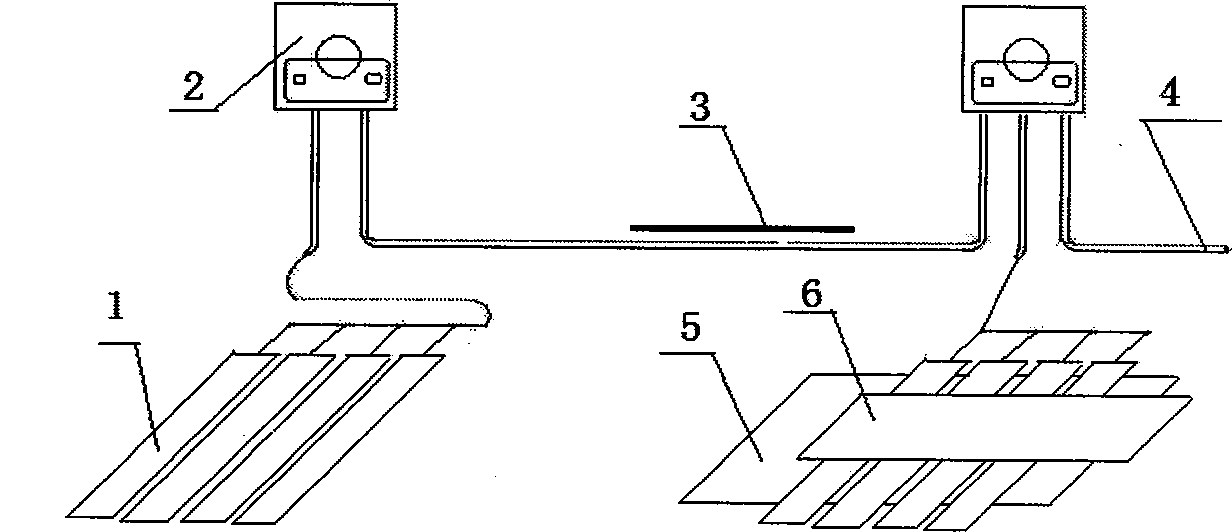

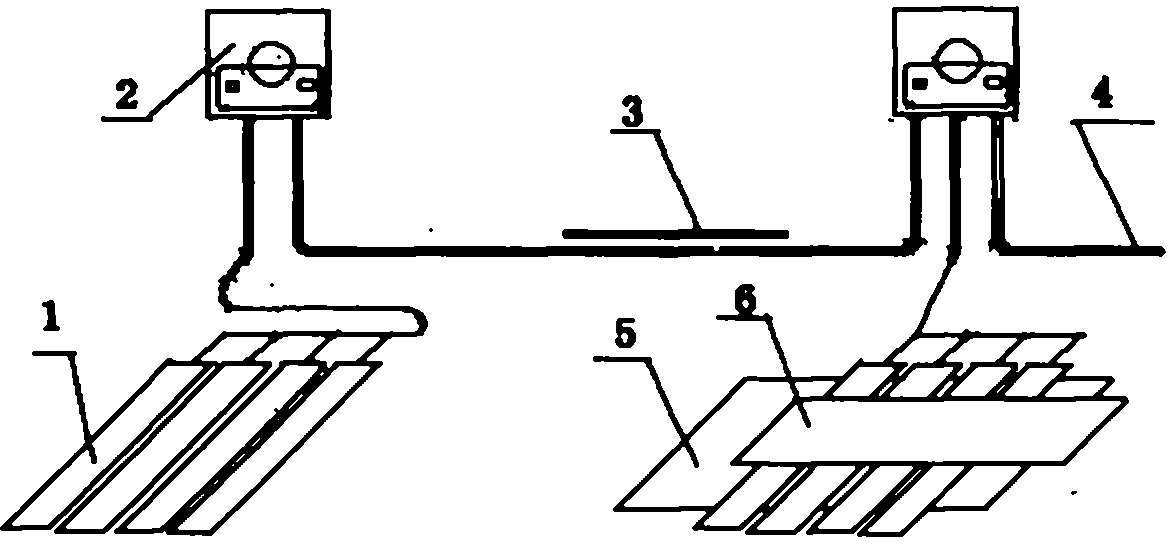

[0013] An insulating layer 5 is installed below the electric heating film 1 , a finishing layer 6 is installed above the electric heating film 1 , and a thermostat 2 is connected to the power supply 4 and the electric heating film 1 . The interior heating floor 3 is generally formed on the facing layer 6 .

[0014] In the present invention, the power supply of each thermostat 2 must be in place, and each thermostat 2 must leave a φ20 PVC pipe to the ground, so that the electric heating film 1 cable can be connected to the thermostat 2, and the thermostat 2 is connected to the pipe bend The distance between the head and the ground is 20mm, and the distance between the temperature controller 2 and the electric heating film is 1300mm. The ground of the power line needs to be laid in the gap of the insulation board, and the temperature controller should be placed in the filling place of the post-cast wall as much as possible.

[0015] In the present invention, the electric heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com