Fluorescent powder lamella, fluorescent powder color wheel, and light source using fluorescent powder lamella

A fluorescent pink wheel and fluorescent powder technology, applied to light sources, optical elements for changing the spectral characteristics of emitted light, components of lighting devices, etc., can solve the problem of reducing luminous efficiency, high laser power density, and failure to reach the optimal value and other issues to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For convenience, um is used in the following description to represent the length unit micrometer.

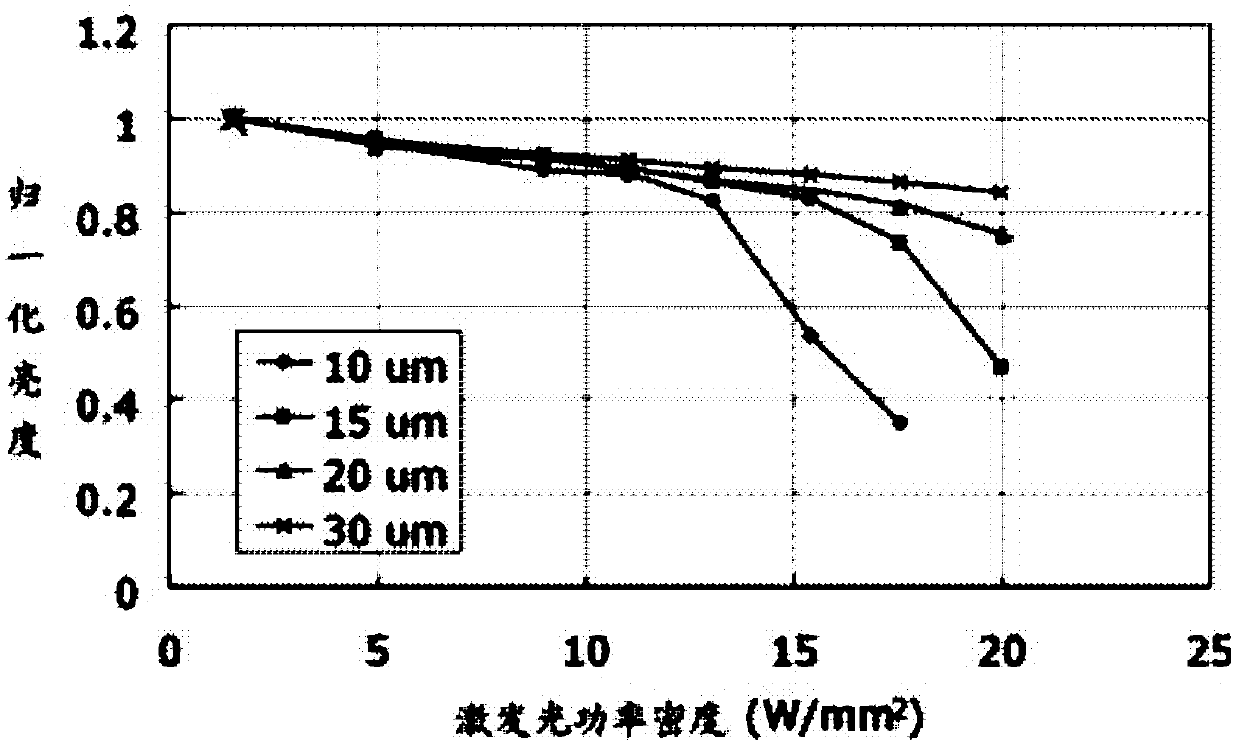

[0024] figure 2 Shown is the normalized luminance curves of phosphor powders with different particle sizes illuminated by excitation light sources with different optical power densities when the phosphor pink wheel of the present invention moves periodically. Excitation light sources include lasers and LEDs, etc. This experiment uses lasers as an example, but it is not limited to this in practical applications.

[0025] Such as figure 2 It can be seen that the brightness and efficiency of phosphors with the same particle size decrease with the increase of the driving current of the excitation light source, especially when the optical power density of the excitation light source increases to a certain threshold, the brightness of the fluorescent light shows an avalanche type of decline. The aforementioned optical power density refers to the maximum optical power densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com