Distributed thermal management system for battery modules

A technology of thermal management system and battery module, applied in the direction of secondary battery, battery temperature control, circuit, etc., to achieve long service life and stability, ensure the overall working performance, and ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Figure 4 It is a schematic structural diagram of Embodiment 1 of a distributed thermal management system for a battery module provided by the present invention when a heating resistor is used for heating operation. At this time, the present invention adopts a solid-state heating method for thermal management.

[0058] see also Figure 4 , for a distributed thermal management system of a battery module provided by the present invention, when using a heating resistor for heating operation, the heating module 200 on each battery module may include a heating resistor 4 and an N-channel MOS switch Tube NMOS, each heating resistor 4 is set on the surface of a battery module;

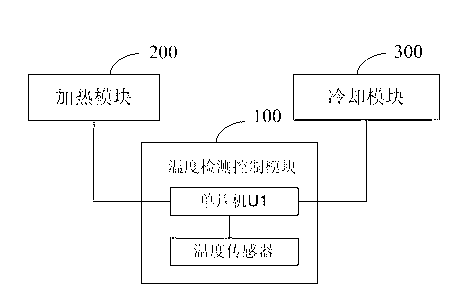

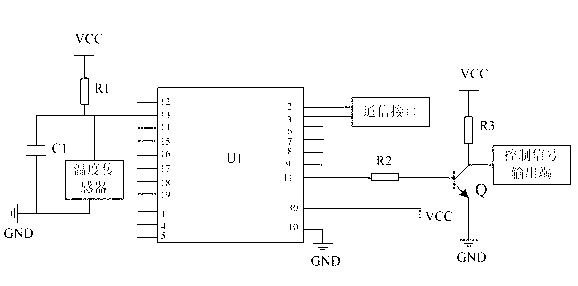

[0059] The gate G of the N-channel MOS switch tube is connected to a control signal output terminal of the single-chip microcomputer U1 (such as figure 2 , image 3 ), the source S of the N-channel MOS switch tube is connected to the heating resistor 4 , and the drain D of the N-channel MOS switch ...

Embodiment 2

[0066] Figure 5 It is a schematic structural diagram of Embodiment 2 of a distributed thermal management system for a battery module provided by the present invention when the air duct is used for heating or cooling operations. At this time, the present invention uses gaseous heating or cooling for thermal management.

[0067] see Figure 5, for a distributed heat management system for battery modules provided in the present invention, when using air ducts for heating or cooling operations, the heating module 200 or the cooling module 300 on each battery module 400 may include The air distribution channel 5 and the valve switch 6, the air distribution channel 5 is formed on the outer wall of the battery module 400, the valve switch 6 is connected to a control signal output terminal of the single chip microcomputer U1 (such as figure 2 , image 3 shown) are connected; the air distribution duct 5 communicates with the top outer wall of the battery module 400, the air divisio...

Embodiment 3

[0073] Image 6 It is a schematic structural diagram of Embodiment 3 of a distributed thermal management system for a battery module provided by the present invention when the liquid channel is used for heating or cooling operations. At this time, the present invention uses a liquid state for heating or cooling thermal management.

[0074] see Image 6 , for a distributed heat management system of a battery module provided in the present invention, when the liquid channel is used for cooling operation, the heating module 200 or cooling module 300 on each battery module 400 may include a flow channel 9 and Valve switch 6, the shunt channel 9 is formed on the outer wall of the battery module 400, the valve switch 6 is connected to a control signal output end of the single chip microcomputer U1 (such as figure 2 , image 3 shown) are connected; the flow channel 9 communicates with the outer wall of the battery module 400, the flow channel 9 communicates with one end of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com