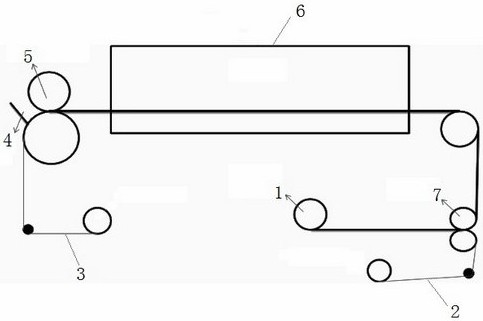

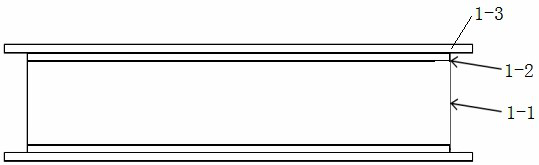

Energy-storage phase-change film composite material, preparation method and application thereof

A thin-film composite material and energy storage phase change technology, which is applied in chemical instruments and methods, synthetic resin layered products, polyurea/polyurethane coatings, etc., can solve problems such as large heat generation, inability to quickly dissipate heat, and high product temperature. Achieve strong heat storage capacity, good heat transfer efficiency, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

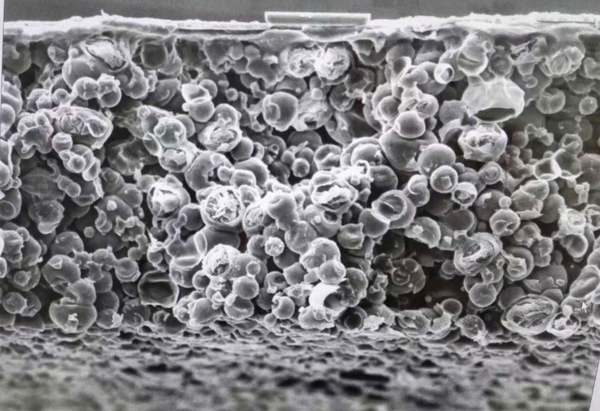

[0048] Mix 40g of melamine, 37% formaldehyde solution and 152g of deionized water, adjust the pH to 7 with triethanolamine, keep the molar ratio of formaldehyde to melamine at 2, mix well and stir at 300r / min in a constant temperature oil bath at 70°C The prepolymerization reaction was carried out at a high speed, and a transparent viscous prepolymer solution was obtained after 30 minutes of reaction; 160g of phase-change paraffin was weighed and placed in a 250ml three-neck flask, 170g of deionized water was added, and the temperature was raised to 70°C to melt the phase-change paraffin. Add 6.4g of emulsifier Tween to dissolve it in water, then use an emulsifier at 10,000r / min to emulsify the paraffin wax for about 30 minutes to obtain a phase-change emulsion; use citric acid solution to adjust the pH of the phase-change emulsion to 4.5, raise the temperature to 80°C, and Slowly add the prepolymer solution dropwise under the stirring of 500r / min, wherein the weight ratio of t...

Embodiment 2

[0055] Mix 40g of melamine, 37% formaldehyde solution and 160g of deionized water, adjust the pH to 8 with triethanolamine, keep the molar ratio of formaldehyde to melamine at 2.5, mix well and stir at 300r / min in a constant temperature oil bath at 70°C The prepolymerization reaction was carried out at a high speed, and a transparent viscous prepolymer solution was obtained after 30 minutes of reaction; 160g of C with a high phase change enthalpy value was weighed 18 Place n-paraffin paraffin in a 250ml three-necked flask, add 160g of deionized water, and raise the temperature to 70°C to melt the phase-change paraffin, add 8g of emulsifier Tween to dissolve it in water, and then use a 20000r / min emulsifier to treat the paraffin Perform emulsification for about 30 minutes to obtain a phase change emulsion; use citric acid solution to adjust the pH of the phase change emulsion to 4.5, raise the temperature to 80°C, and slowly add the prepolymer solution dropwise under stirring at...

Embodiment 3

[0061] Mix 40g of melamine, 37% formaldehyde solution and 168g of deionized water, adjust the pH to 8.5 with triethanolamine, keep the molar ratio of formaldehyde to melamine at 3, mix well and stir at 300r / min in a constant temperature oil bath at 70°C The prepolymerization reaction was carried out at a high speed, and a transparent viscous prepolymer solution was obtained after 30 minutes of reaction; 160g of phase-change paraffin was weighed and placed in a 250ml three-neck flask, 150g of deionized water was added, and the temperature was raised to 70°C to melt the phase-change paraffin. Add 9.6g of emulsifier Tween to dissolve it in water, and then use a 30000r / min emulsifier to emulsify the paraffin wax for about 30 minutes to obtain a phase-change emulsion; use citric acid solution to adjust the pH of the phase-change emulsion to 4.5, raise the temperature to 80°C, and Slowly add the prepolymer solution dropwise under the stirring of 500r / min, wherein the weight ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com