New-energy automobile power battery thermal management device and method

A new energy vehicle, power battery technology, applied in battery/fuel cell control devices, electric vehicles, secondary batteries, etc., can solve the problems of short cruising range, unbalanced thermal management, weak working temperature adjustment ability, etc., and achieve high efficiency Thermal management, improving battery life and efficiency, addressing the effects of short cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

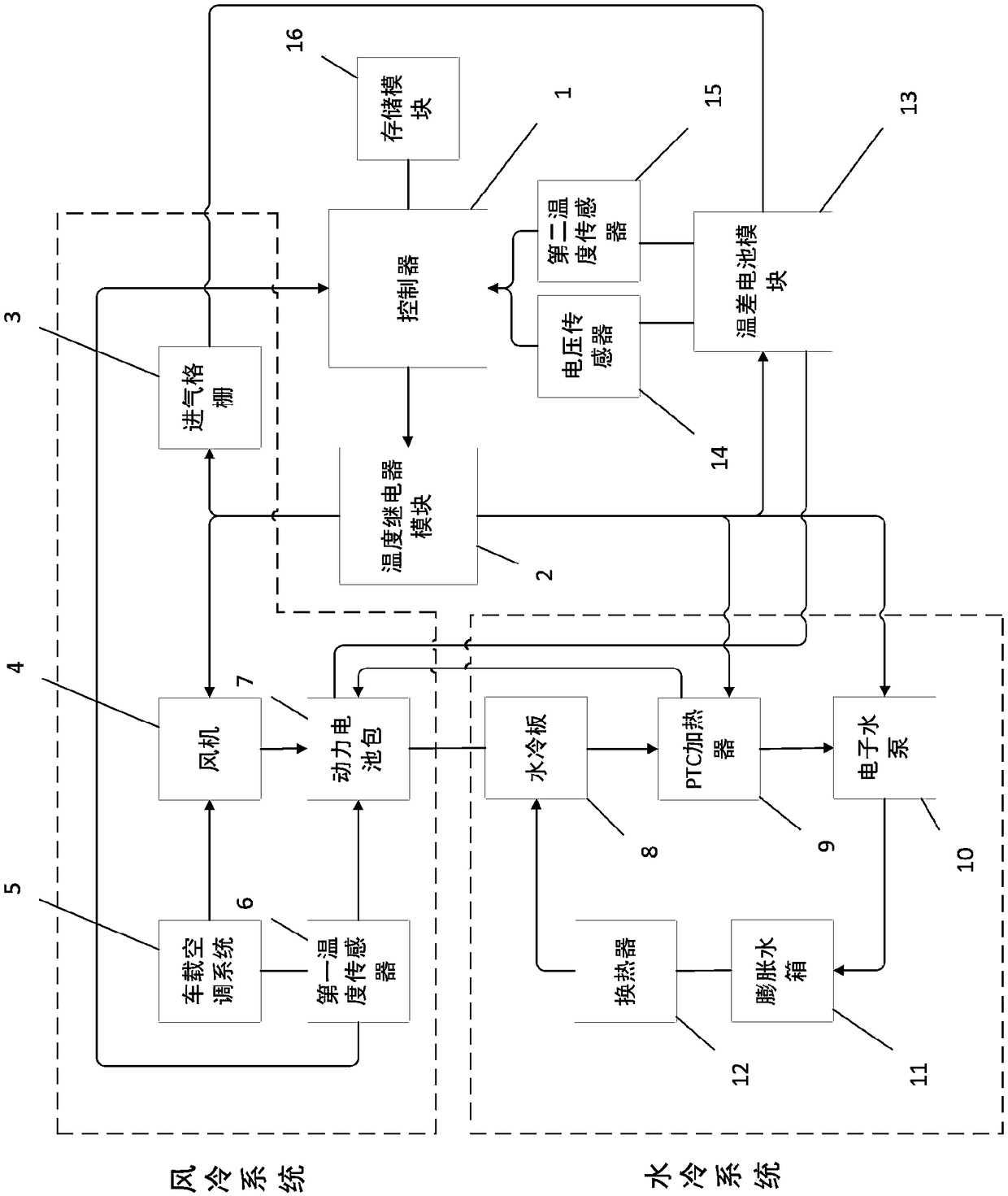

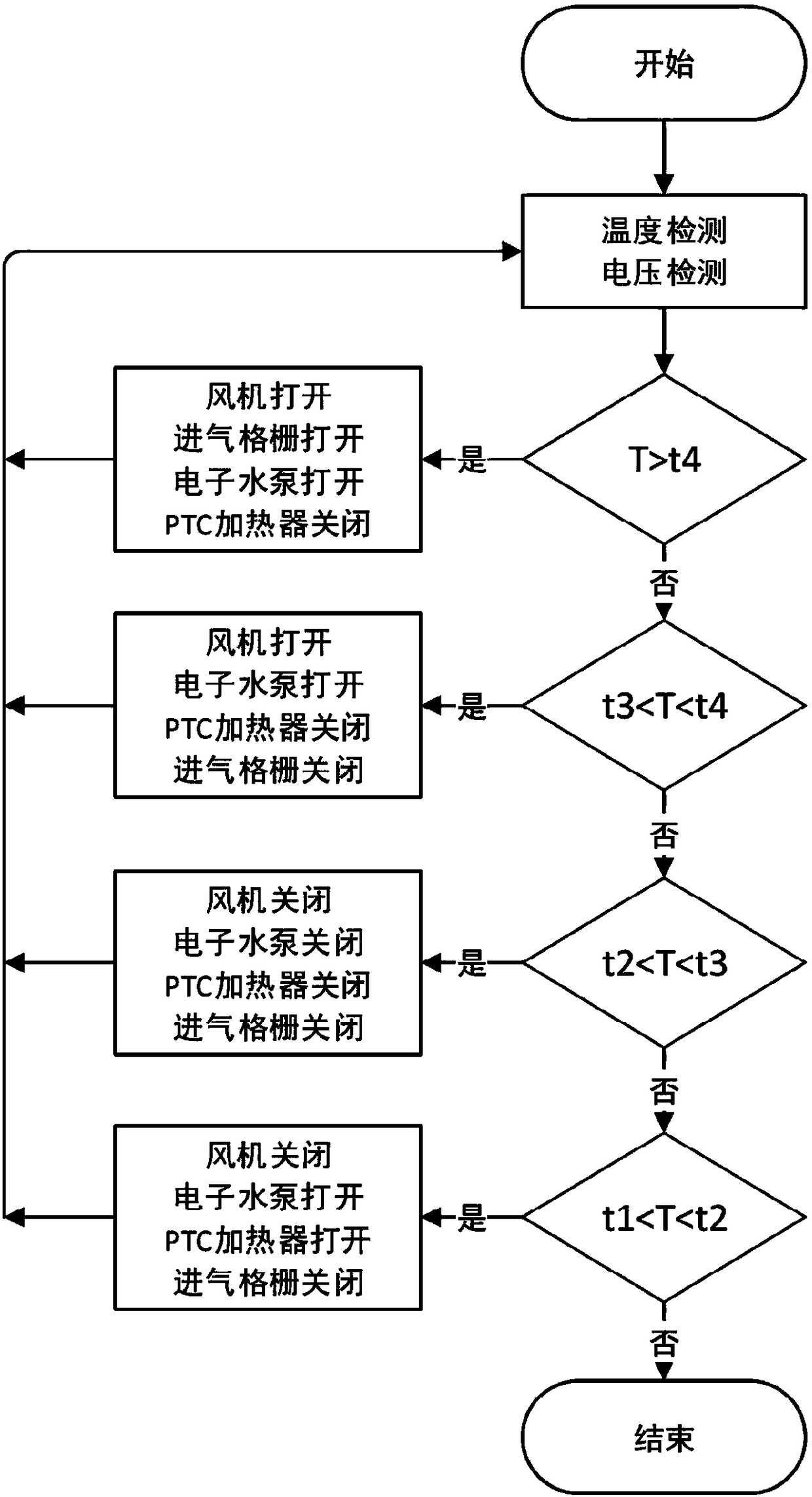

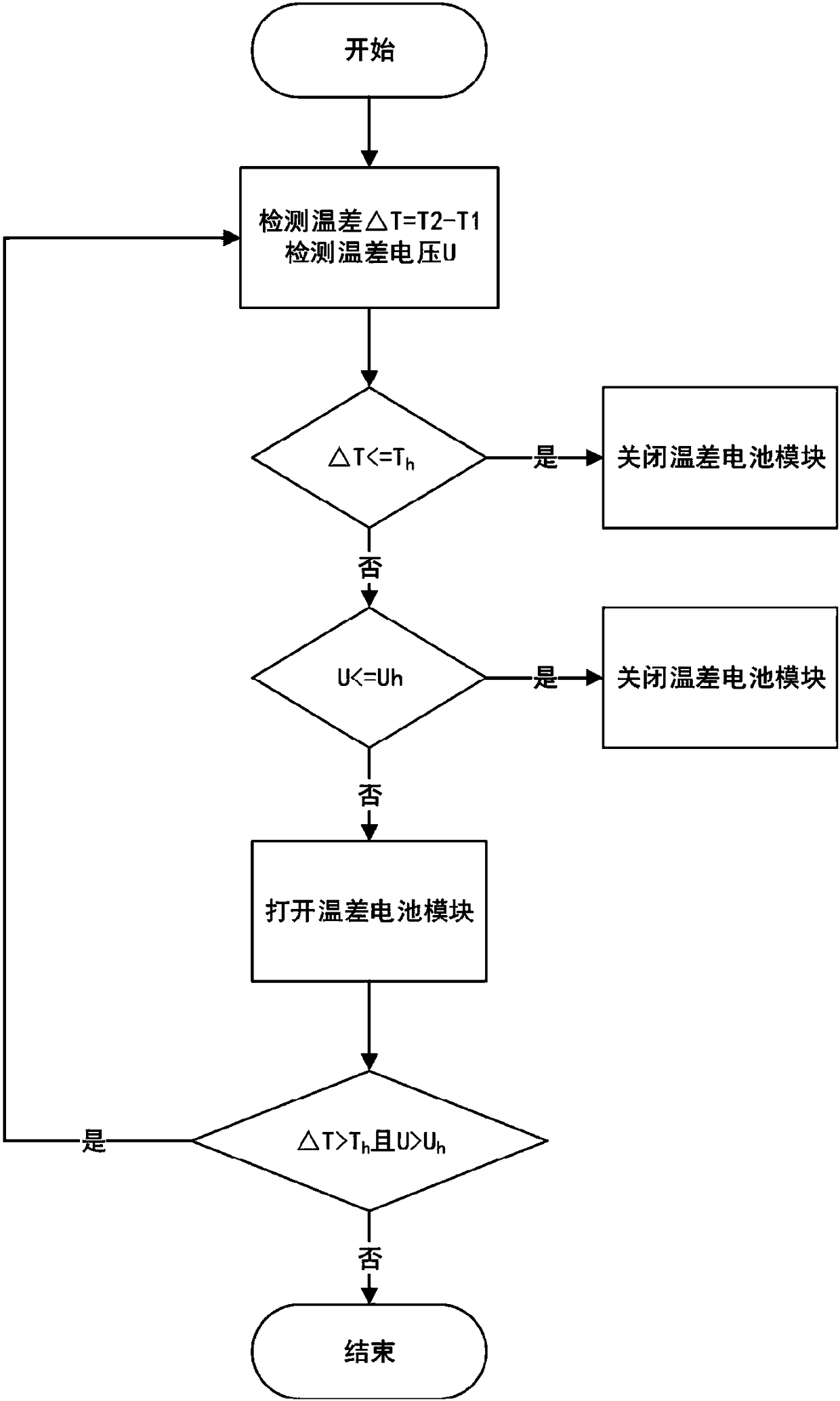

[0029] see figure 1, the present invention relates to a new energy vehicle power battery thermal management device, including a controller 1, a temperature relay module 2, an air intake grille 3, a fan 4, a vehicle air conditioning system 5, a first temperature sensor 6, a power battery pack 7, Water cooling plate 8 , PTC heater 9 , electronic water pump 10 , expansion tank 11 , heat exchanger 12 , thermoelectric battery module 13 , voltage sensor 14 , second temperature sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com