Cable deicing robot for transmission line

A technology of cables and power lines, applied in the field of deicing robots, can solve the problems of low efficiency, achieve high automation, improve work efficiency, and uniquely design the effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in more detail below in conjunction with accompanying drawing example:

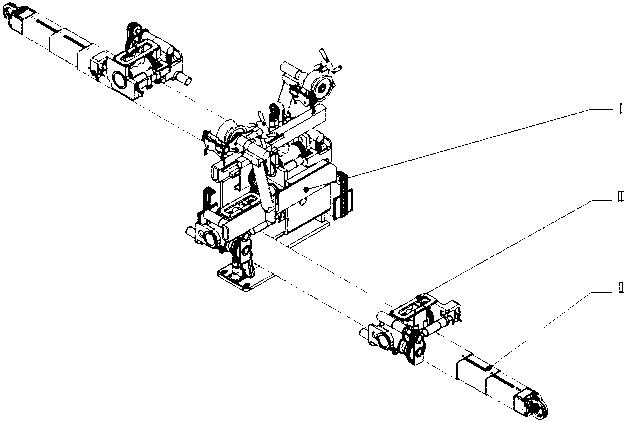

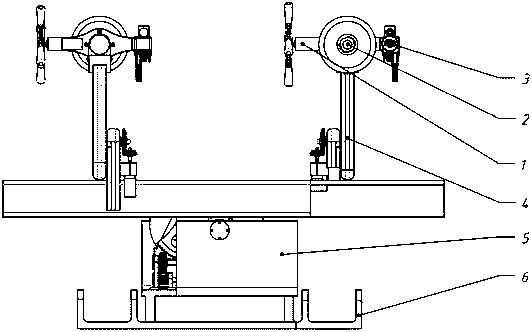

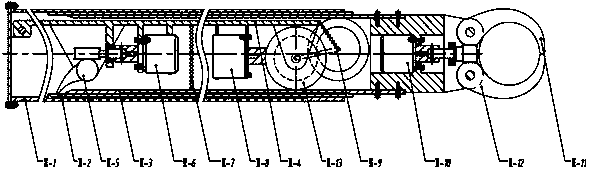

[0032] combine Figure 1-12 , the high-voltage line multi-cable simultaneous deicing robot is mainly composed of a main body obstacle surmounting device I, a telescopic arm II, and a deicing trolley III.

[0033] Its features are: first, the left and right telescopic arms are unfolded and hooked on the cables on both sides, then the deicing trolleys move to the ends of the telescopic arms respectively and climb over the cables on both sides, the main body and the trolley deicing at the same time to realize the deicing of three cables at the same time Deicing; secondly, when an obstacle is encountered, the two telescopic arms and the trolley are retracted, and the main obstacle surmounting device moves back and forth relatively, rotates up and down, and the support arm swings left and right through the two outstretched arms on it, so that the entire robot can cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com