High-voltage power transmission line inspection robot mechanism

A technology for patrolling robots and high-voltage transmission lines, which is applied to manipulators, program-controlled manipulators, overhead lines/cable equipment, etc. Large center of mass adjustment range, strong climbing and moving capabilities, and the effect of reducing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

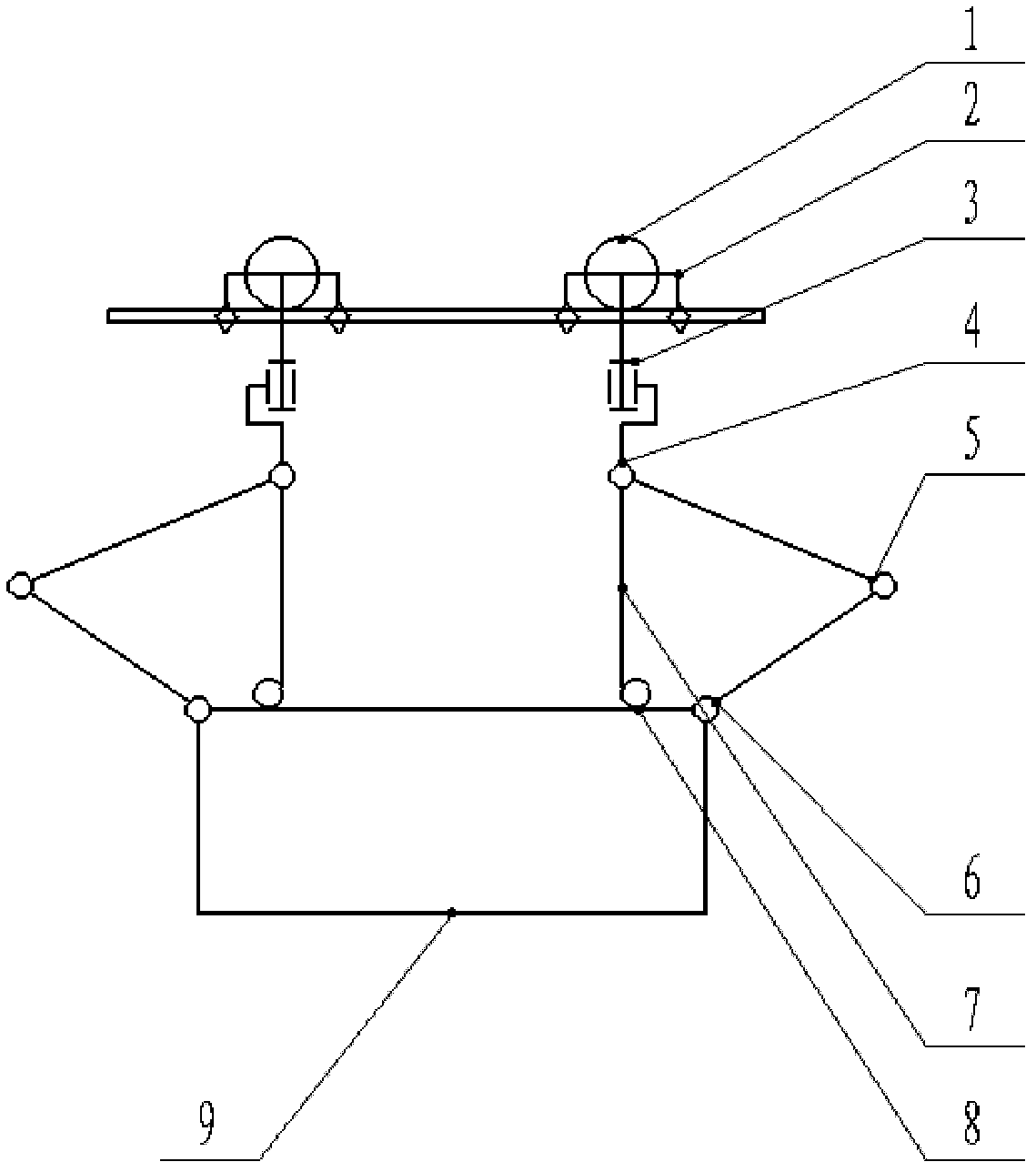

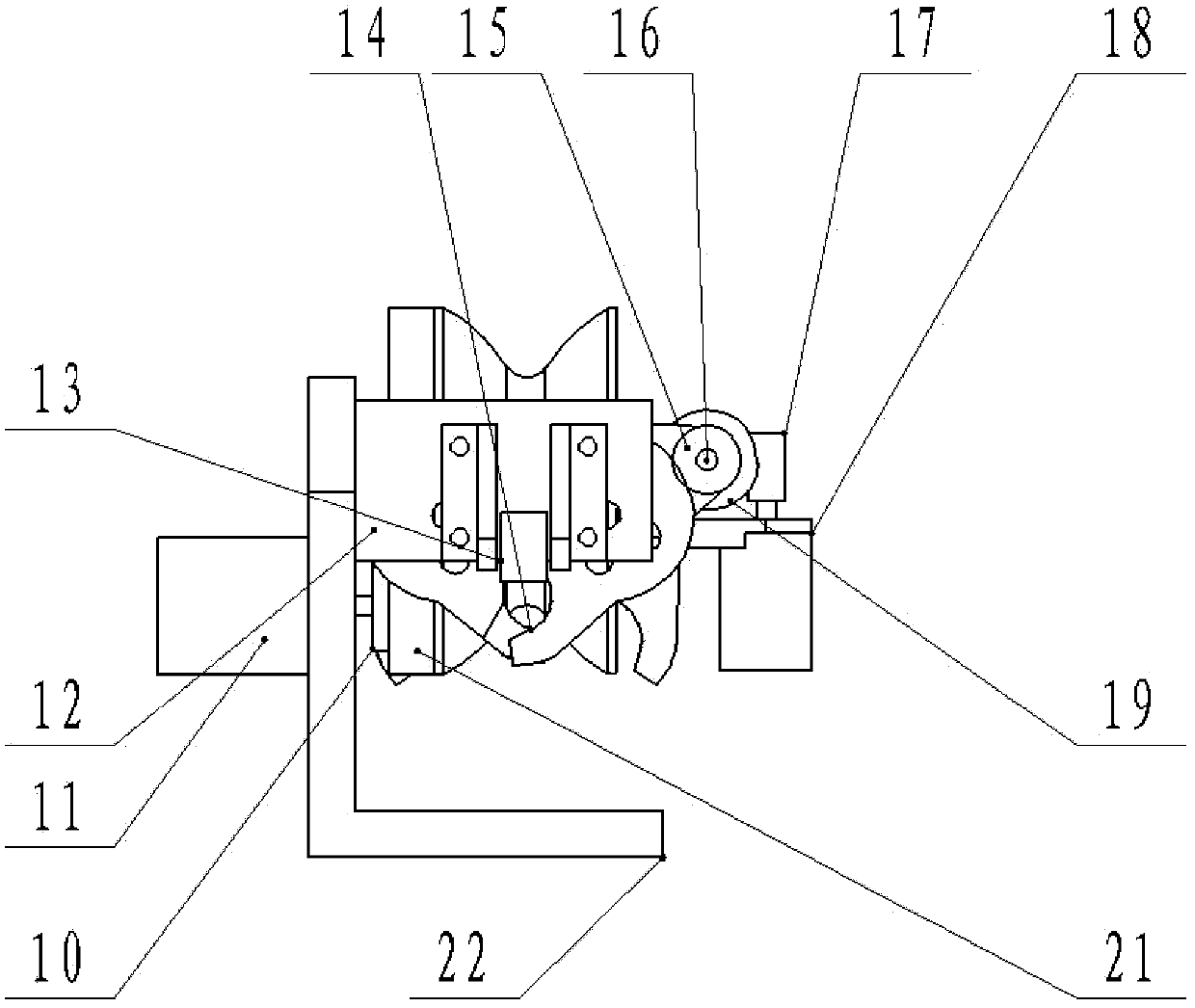

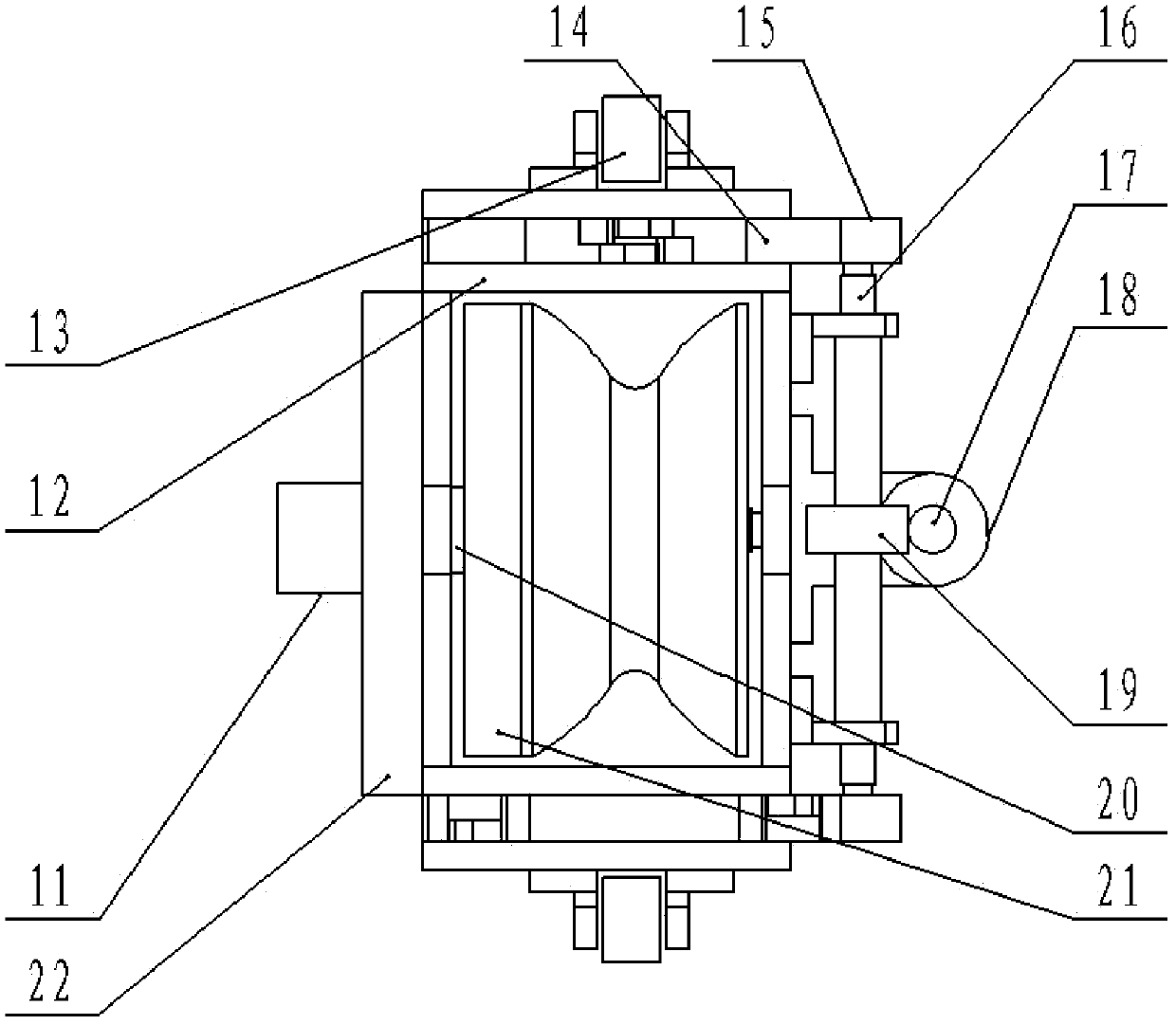

[0023] Such as figure 1 As shown, the high-voltage transmission line inspection robot mechanism of the present invention includes a front claw, a front arm, a center of mass adjustment structure, a rear arm and a rear claw, and the front claw and the rear claw are respectively connected to the ends of the front arm and the rear arm, and Gripping with the line, the claw is a combined structure of a gear pair and a worm gear. The two arms have the same structure, including a horizontal rotation pair 3 and three vertical rotation pairs 4, 5, 6. The center of mass adjustment structure includes a box 9 , roller moving platform 8 and soft cable 7, the two ends on the upper surface of the box body 9 are respectively connected to the third vertical rotation pair 6 of the front arm and the front end of the rear arm, and the two roller moving platforms 8 are symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com