Large-capacity inversion grid-connected device

A large-capacity, inverter technology, applied in the direction of irreversible DC power input conversion to AC power output, single-network parallel feeding arrangement, conversion equipment that can be converted to DC without intermediate conversion, etc., can solve the problem of high production cost High and low production efficiency, etc., to achieve the effect of simple and reasonable process structure, low cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

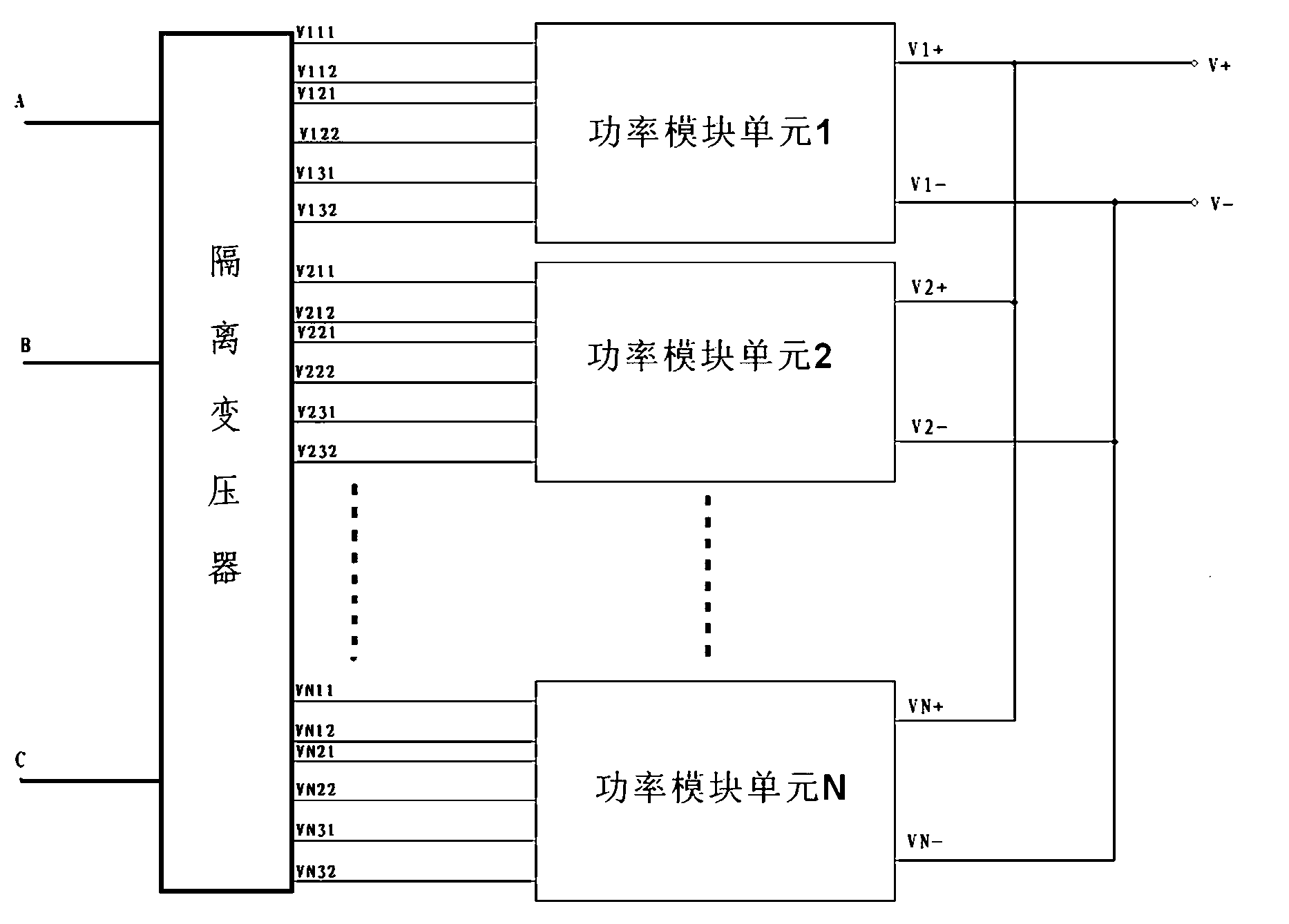

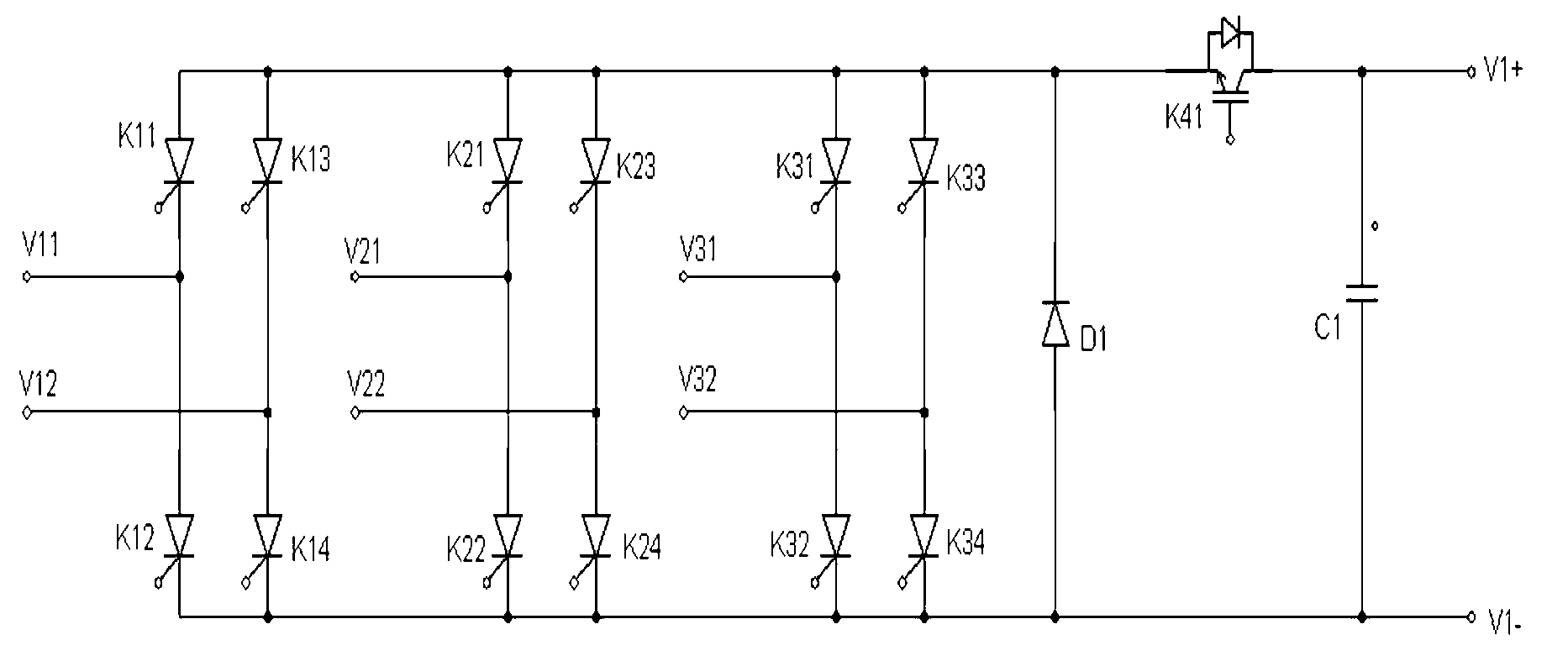

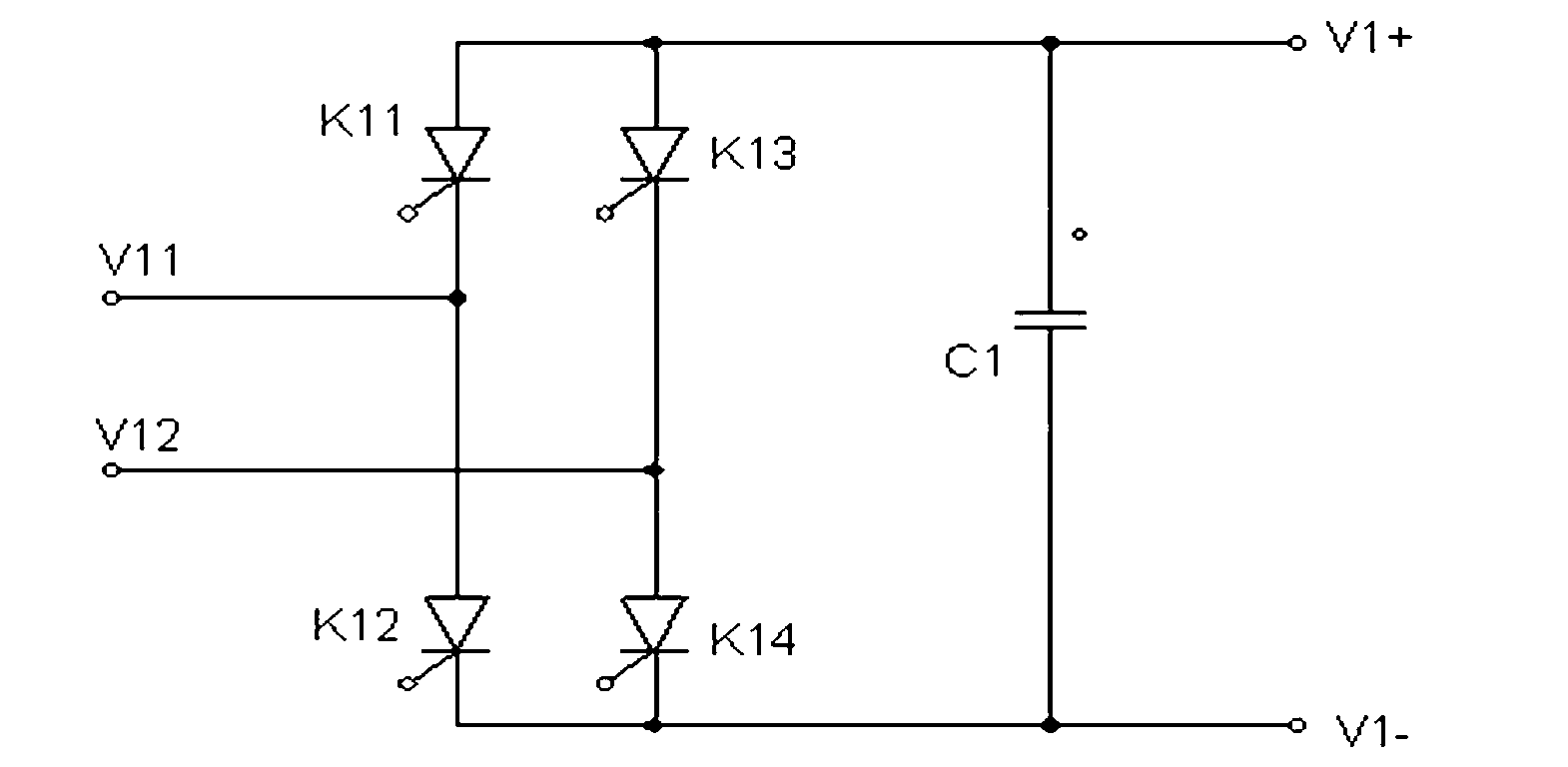

[0029] Such as figure 1 As shown, the system circuit block diagram of the inverter grid-connected device of the present invention is given, the input terminals of power module unit 1, power module unit 2, ..., power module unit n are respectively connected to the V+ and V- terminals of direct current, In this way, each power module unit is connected in parallel. The output terminals V111, V112, V121, V122, V122, V131, V132, ... ... VN32 of the power module unit are respectively connected to the secondary windings V111, V112, V121, V122, V122, V131, V132, ... ... VN32 of the isolation transformer , and then form the total output through the three-phase windings A, B, and C on the primary side of the transformer, and then connect it to the grid. By increasing or decreasing the number of power module units, grid-connection of DC power with different capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com