Printed circuit board realizing weldable metal mini-heat-radiators by metal aluminum and manufacturing method of printed circuit board

A printed circuit board, welding metal technology, applied in the direction of printed circuit components, etc., can solve the problems of changing the life of power devices, failure of power devices, affecting the performance of power devices, etc., to achieve long service life, high thermal conductivity substrate performance, excellent surface processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The invention provides a printed circuit board, which can effectively solve the technical problems of heat transfer and heat dissipation in the printed circuit board provided by the prior art.

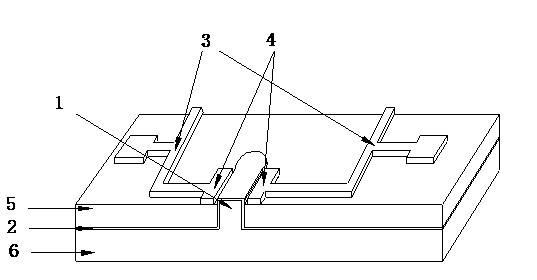

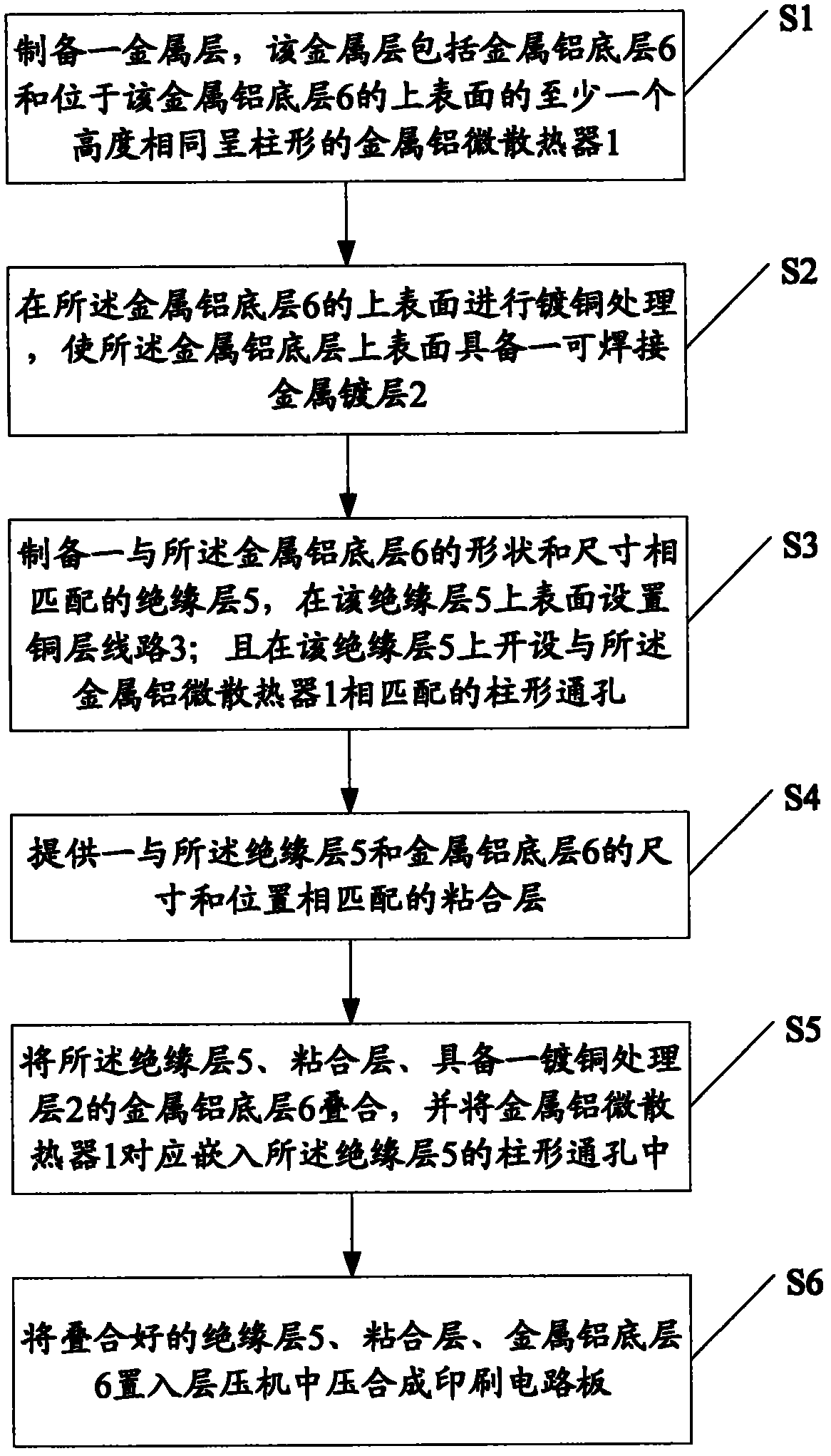

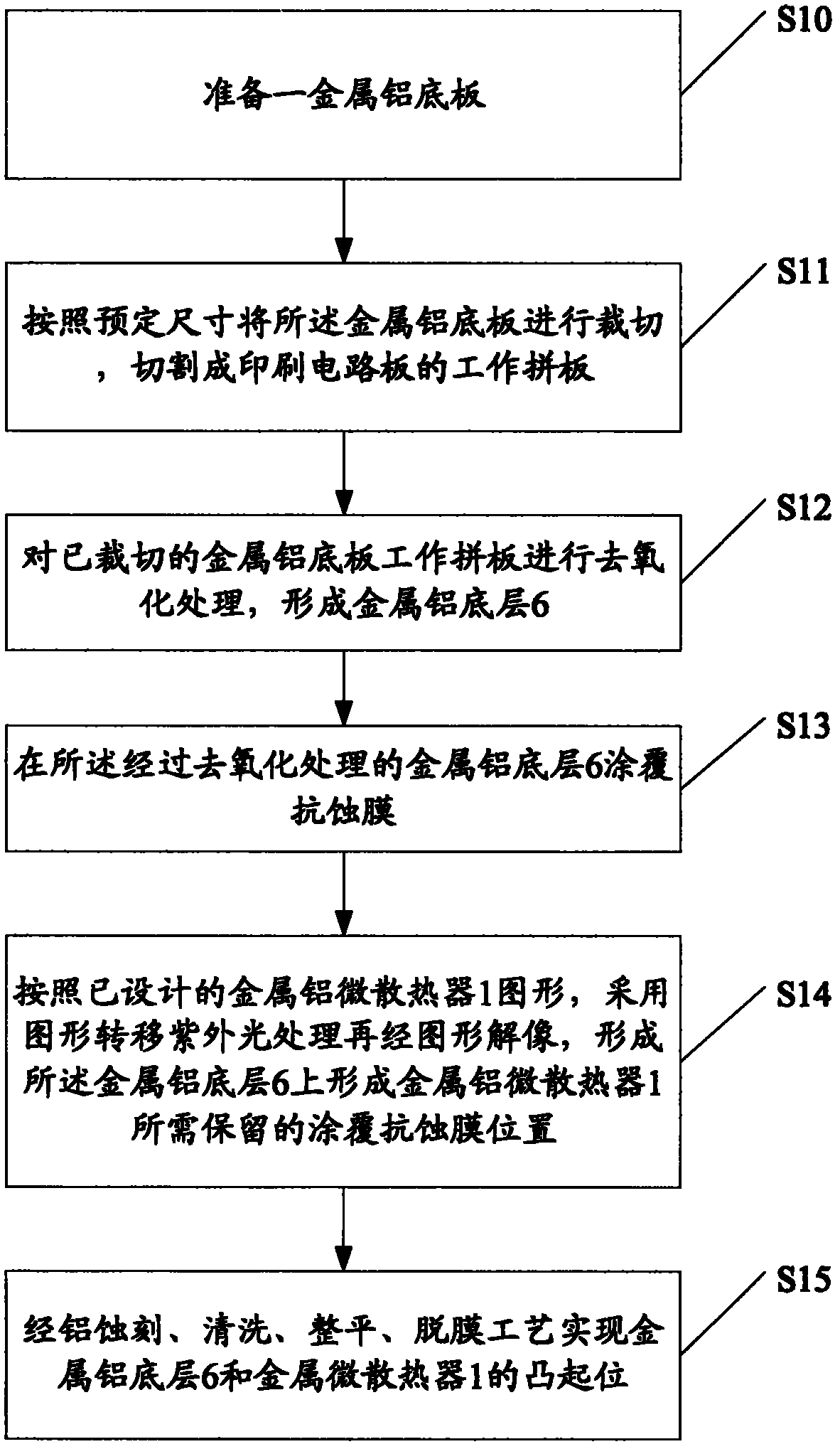

[0052] see figure 1 , which is a structural schematic diagram of a printed circuit board that uses metal aluminum to realize a weldable metal micro radiator provided by the present invention.

[0053] figure 1 A printed circuit board that uses metal aluminum to realize a weldable metal micro radiator includes:

[0054] The metal aluminum bottom layer 6 and the insulation layer 5 are stacked; the upper surface of the insulation layer 5 away from the metal aluminum bottom layer 6 is provided with a copper layer circuit 3;

[0055] The upper surface of the metal aluminum bottom layer 6 in contact with the insulating layer 5 is a weldable metal coating 2;

[0056] The insulating layer 5 is provided with at least one columnar through hole, and the printed circuit board also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com