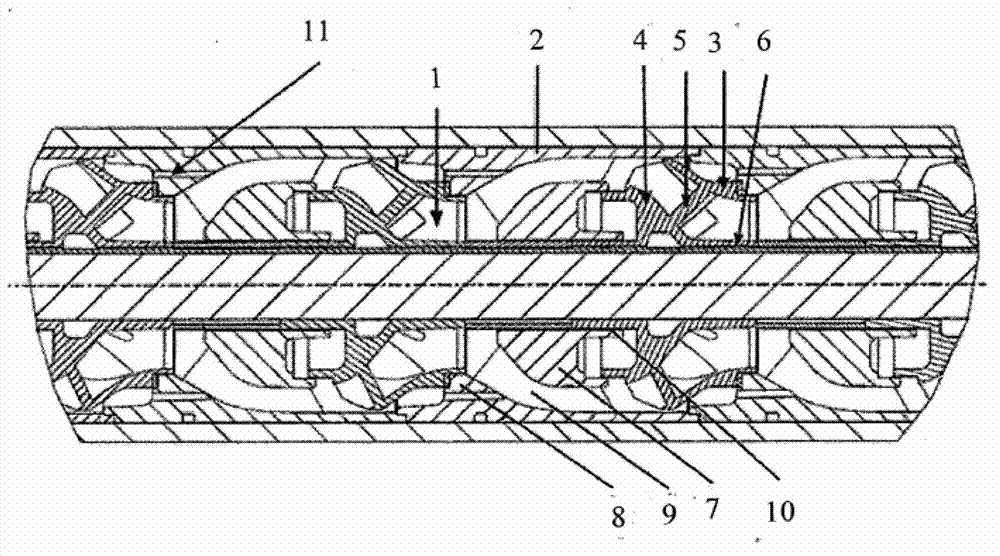

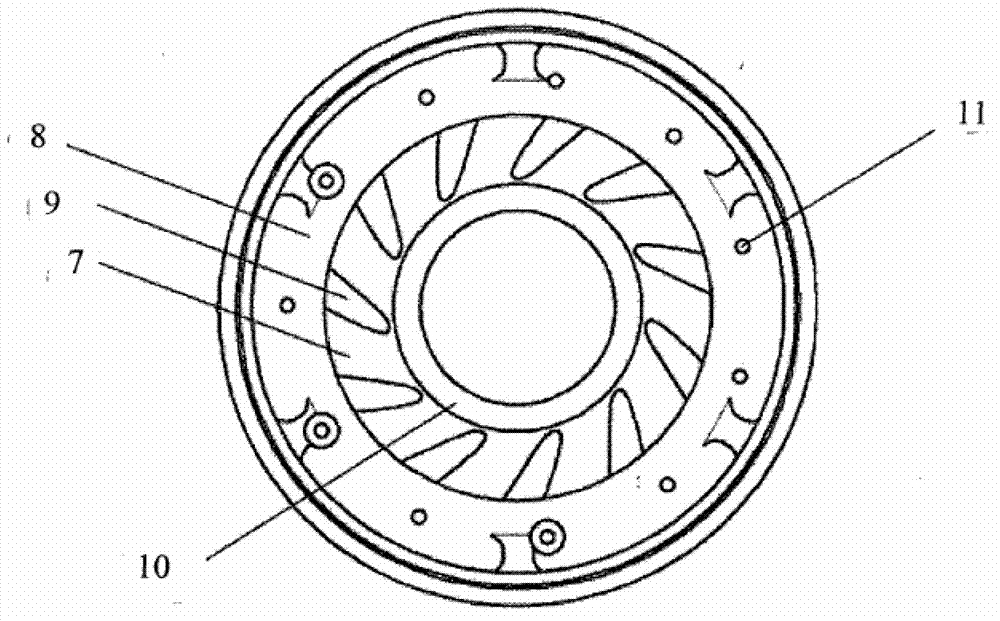

Submersible pump stage

A technology of submersible pumps and pump stages, which is applied in the direction of pumps, pump devices, pump components, etc., and can solve the problems of electric motor breakdown, increased friction, impeller cover plate grinding and wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to avoid the collapse of the electric motor, it is necessary to ensure that the front bag is continuously forced to flush. One option for the front bladder flush implementation is to configure special "grind" holes that connect the submersible pump stage front bladder to the guide of the submersible pump's previous stage. In this case, a recirculation movement of liquid occurs in the front pocket, which does not allow the accumulation of solid particles, and the movement of the liquid through the "grinding" holes transports the solid particles out of the pocket cavity to the previous stage of guidance device, solid particles are conveyed from the guide device to the pump stage inlet again. The suction of liquid through the "grind" holes is ensured by the pressure difference between the front bladder of the current stage and the diffuser of the previous stage. The pressure differential at the "grind" holes is approximately equal to the hydraulic pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com