Processing method for leatherworking waste water

A treatment method and technology for processing wastewater, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

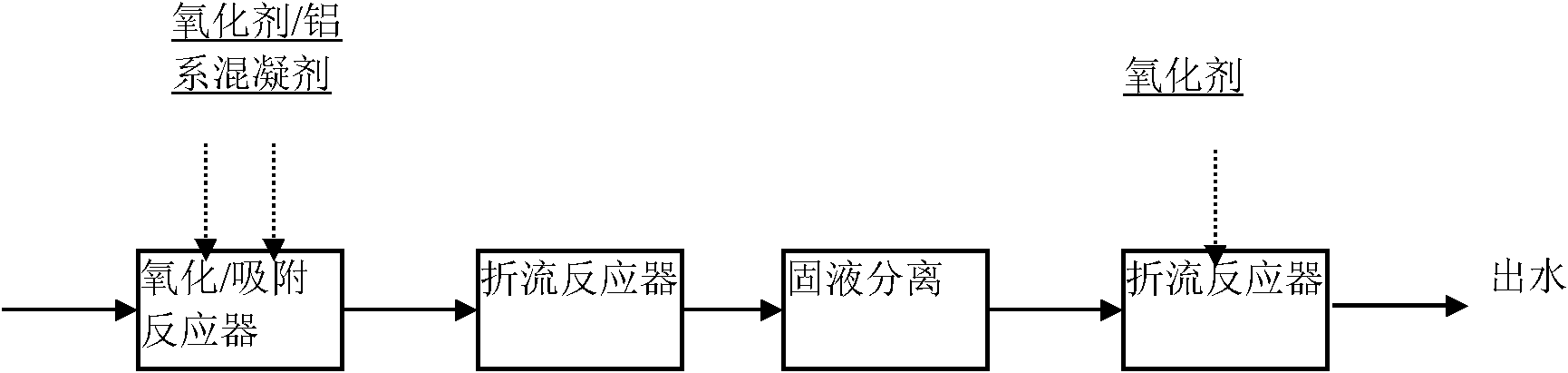

Image

Examples

Embodiment 1

[0025] The leather processing sewage after the biochemical treatment was taken for the test. This sewage COD cr 94mg / l, pH=7.5. The sewage is subjected to advanced treatment by adopting the treatment process of the present invention. First, add 2 mg / l potassium ferrate (oxidant) and 10 mg / l polyaluminum chloride (aluminum coagulant) to the sewage to react for 10 minutes, use the oxidant to degrade the organic matter in the sewage, and at the same time dissolve the water-soluble Pollutants are oxidized to be insoluble in water, which is convenient for coagulation and separation by aluminum-based coagulants.

[0026] Wastewater enters the first separation flow reactor for 5-30 minutes of oxidative adsorption baffle reaction, and then enters the sand filter for solid-liquid separation. The filtration rate of the filter is 5-6m / h; the flocculant PAM can be added for solid-liquid separation. To enhance the flocculation effect, the dosage is 2-8mg / l.

[0027] Wastewater after so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com