Method for treating underflow slag of wastewater with sedimentated vanadium and hydrometallurgical vanadium extraction process

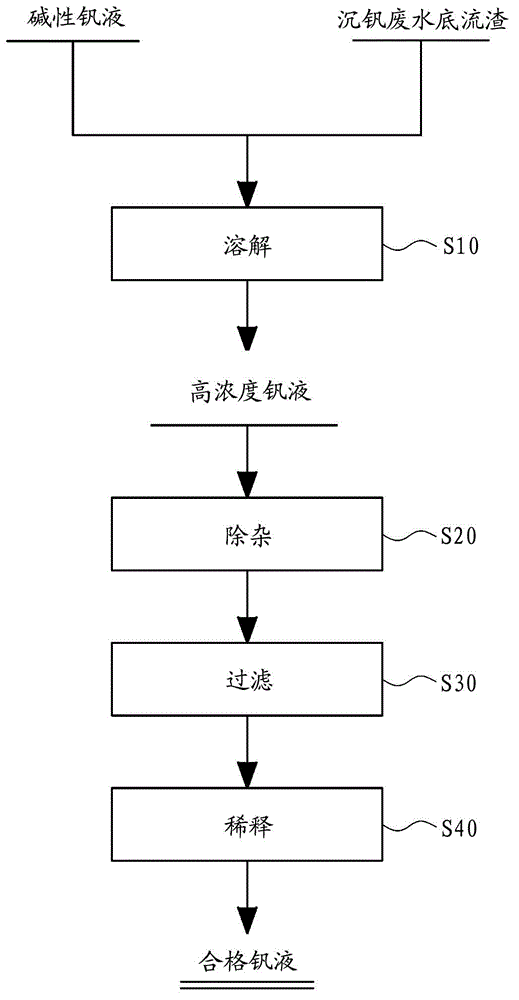

A technology for vanadium precipitation wastewater and underflow slag is applied in the direction of improving process efficiency, which can solve problems such as difficulty in wastewater treatment and unqualified product quality, and achieve the effect of optimizing process steps and simplifying operation and treatment processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Take 2L of alkaline vanadium liquid (the concentration of total vanadium is 25.2g / L, the content of P is 0.05g / L, the pH value is 9.5, and the temperature is 70°C), add 160g of the underflow slag of the vanadium precipitation wastewater (the content of ammonium polyvanadate accounts for 94 %, the pH value is 4.2), after stirring for 30min, add impurity remover CaCl 2 0.54g, and continue to stir and react for 20 minutes, and filter to obtain a high-concentration vanadium solution with a pH value of 6.2 and a vanadium loss of 0.015%.

example 2

[0033] Take 4L of alkaline vanadium liquid (total vanadium concentration is 35g / L, P content is 0.07g / L, pH value is 11, temperature is 90 DEG C), add 320g of vanadium precipitation wastewater underflow slag (content of ammonium polyvanadate accounts for 92% , pH value is 5), after stirring for 30min, add impurity remover CaCl 2 1.52g, and continuously stirred for 20 minutes, filtered to obtain a high-concentration vanadium solution with a pH value of 6.5 and a vanadium loss of 0.01%.

example 3

[0035] Take 3L of alkaline vanadium liquid (total vanadium concentration is 25g / L, P content is 0.045g / L, pH value is 9, temperature is 60 DEG C), add 240g of vanadium precipitation waste water underflow slag (content of ammonium polyvanadate accounts for 96%) , pH value is 3), after stirring for 30min, add impurity remover CaCl 2 0.73g, continue to stir and react for 20 minutes, and filter to obtain a high-concentration vanadium solution with a pH value of 6.4 and a vanadium loss of 0.014%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com