Stainless steel composite steel butt-welded pipe fitting heat treatment process

A technology for stainless steel and pipe fittings, applied in the field of heat treatment process of stainless steel composite butt welded pipe fittings, can solve the problems of influence, quality damage, temperature difference, etc., and achieve the effects of good comprehensive benefits, alleviation of high temperature impact, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

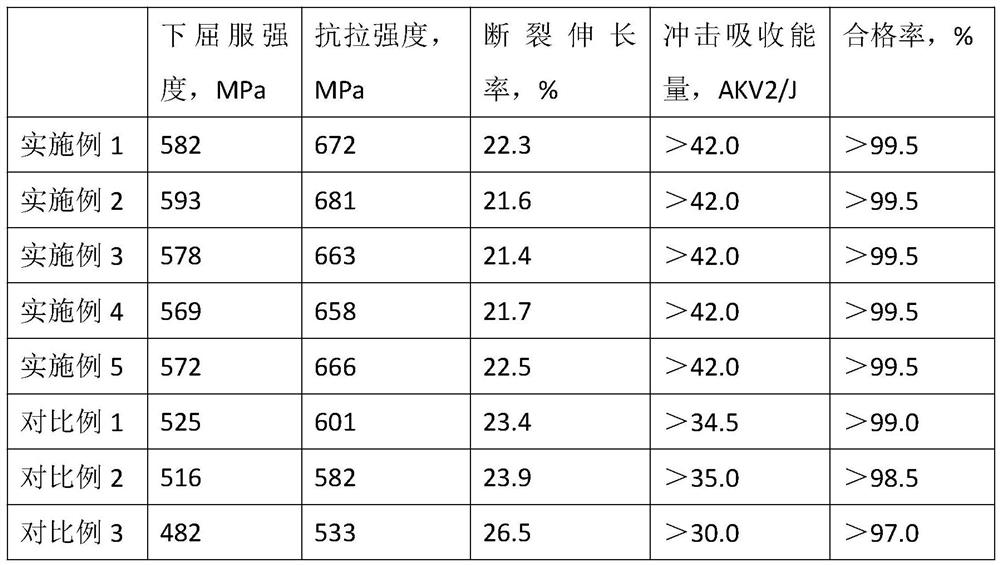

Examples

Embodiment 1

[0024] A heat treatment process for stainless steel composite steel butt-welding pipe fittings, including primary treatment, preheating, two-stage quenching, secondary treatment, and one-stage tempering, wherein the primary treatment and secondary treatment are heat transfer fluids with different lubricating oil contents Coating of pipes to be processed.

[0025] Among them, the heat transfer liquid includes hydrophobic silica sol particles, silicon nitride particles, and polyacrylic acid emulsion, and the mass ratio of the three is 5:1:28. Moreover, the hydrophobic silica sol particles are methyltriethoxysilane modified silica sol, the oil contact angle is 8.6±1.3°, the hydrophobic silica sol particles are dried and crushed to a D90 of 50 μm, and the particle size of the silicon nitride particles is The solid content of the polyacrylic acid emulsion is 38% if it is less than 1 μm.

[0026] Further, the lubricating oil is 3# nano-based lubricating oil, the lubricating oil acc...

Embodiment 2

[0036] A heat treatment process for stainless steel composite steel butt-welding pipe fittings, including primary treatment, preheating, two-stage quenching, secondary treatment, and one-stage tempering, wherein the primary treatment and secondary treatment are heat transfer fluids with different lubricating oil contents Coating of pipes to be processed.

[0037] Wherein, the heat transfer liquid includes hydrophobic silica sol particles, silicon nitride particles, and polyacrylic acid emulsion, and the mass ratio of the three is 3:0.5:15. Moreover, the hydrophobic silica sol particles are methyltriethoxysilane modified silica sol, the oil contact angle is 8.6±1.3°, the hydrophobic silica sol particles are dried and crushed to a D90 of 50 μm, and the particle size of the silicon nitride particles is The solid content of the polyacrylic acid emulsion is 38% if it is less than 1 μm.

[0038] Further, the lubricating oil is 3# nano-based lubricating oil, and the lubricating oil ...

Embodiment 3

[0048] A heat treatment process for stainless steel composite steel butt-welding pipe fittings, including primary treatment, preheating, two-stage quenching, secondary treatment, and one-stage tempering, wherein the primary treatment and secondary treatment are heat transfer fluids with different lubricating oil contents Coating of pipes to be processed.

[0049] Wherein, the heat transfer liquid includes hydrophobic silica sol particles, silicon nitride particles, and polyacrylic acid emulsion, and the mass ratio of the three is 2:0.6:20. Moreover, the hydrophobic silica sol particles are methyltriethoxysilane modified silica sol, the oil contact angle is 8.6±1.3°, the hydrophobic silica sol particles are dried and crushed to a D90 of 50 μm, and the particle size of the silicon nitride particles is The solid content of the polyacrylic acid emulsion is 38% if it is less than 1 μm.

[0050] Further, the lubricating oil is 3# nano-based lubricating oil, and the lubricating oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com