Energy-saving high-performance powder metallurgy

A powder metallurgy, high-performance technology, applied in the field of metallurgy, can solve the problems of high energy consumption, low tensile strength and hardness, and low process production efficiency, and achieve the effects of good energy saving, good compactness, and small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

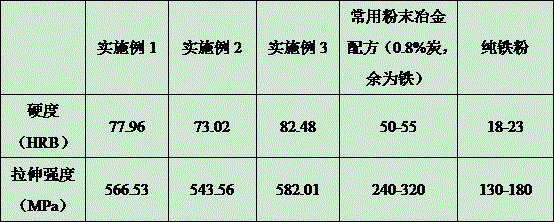

Examples

preparation example Construction

[0041] The energy-saving high-performance powder metallurgy preparation method includes the following steps:

[0042] S1: Combine stainless steel powder, yttrium powder, molybdenum powder, zinc oxide, manganous sulfide, aluminum oxide, electrolytic copper, graphite powder, fatty acids, cutting agents, lubricants, strengthening agents, binders, tackifiers, and antiwear agents , The processing aids and regulators are introduced into the mixing barrel and stirred to form a mixed powder. After being evenly stirred, it is filtered through a filter screen. The particles in the mixed powder with a particle size larger than 140-160 mesh are separated and collected, then crushed and then screened. Then pour into each standard dose bucket for use;

[0043] The preparation method of the cutting agent includes the following steps:

[0044] Step 1. Combine cutting oil, tripropyl phosphate, calcium dinonylnaphthalenesulfonate, 2,6-di-tert-butyl p-cresol, dodecenyl succinic acid, triethanolamine b...

Embodiment 1

[0053] An energy-saving high-performance powder metallurgy, based on weight, made of the following raw materials: 160 parts of stainless steel powder, 5 parts of yttrium powder, 2.5 parts of molybdenum powder, 1.5 parts of zinc oxide, 1.5 parts of manganous sulfide, 1.2 parts of alumina, 1.2 parts of electrolytic copper, 0.9 parts of graphite powder, 4 parts of fatty acids, 0.5 parts of cutting agents, 0.5 parts of lubricants, 0.1 parts of strengthening agents, 0.7 parts of binders, 0.1 parts of tackifiers, 0.7 parts of antiwear agents, and processing aids 0.2 part, 0.1 part of regulator;

[0054] The particle size of the stainless steel powder, yttrium powder, molybdenum powder, zinc oxide, manganous sulfide, aluminum oxide, electrolytic copper, and graphite powder is 0.1-100 μm;

[0055] The cutting agent is based on weight and is made of the following raw materials: 15 parts of cutting oil, 11 parts of tripropyl phosphate, 5 parts of calcium dinonylnaphthalenesulfonate, and 8 pa...

Embodiment 2

[0075] An energy-saving high-performance powder metallurgy, based on weight, made of the following raw materials: 130 parts of stainless steel powder, 4 parts of yttrium powder, 2 parts of molybdenum powder, 1 part of zinc oxide, 1.2 parts of manganous sulfide, 0.9 parts of alumina, 0.8 part of electrolytic copper, 0.6 part of graphite powder, 3 parts of fatty acid, 0.4 part of cutting agent, 0.3 part of lubricant, 0.1 part of strengthening agent, 0.6 part of binder, 0.1 part of tackifier, 0.5 part of anti-wear agent, processing aid 0.2 part, 0.1 part of regulator;

[0076] The particle size of the stainless steel powder, yttrium powder, molybdenum powder, zinc oxide, manganous sulfide, aluminum oxide, electrolytic copper, and graphite powder is 0.1-100 μm;

[0077] The cutting agent is based on weight and is made of the following raw materials: 14 parts of cutting oil, 10 parts of tripropyl phosphate, 4 parts of calcium dinonylnaphthalenesulfonate, and 6 parts of 2,6-di-tert-butyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com