High-temperature-resistant conveyor belt covering rubber and development method thereof

A conveyor belt and high temperature resistant technology, applied in the field of high temperature resistant conveyor belt cover rubber and research and development, can solve the problems of conveying 200°C or even higher temperature, not meeting the use requirements, wasting time, etc., to improve the use range and excellent heat resistance Sex, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

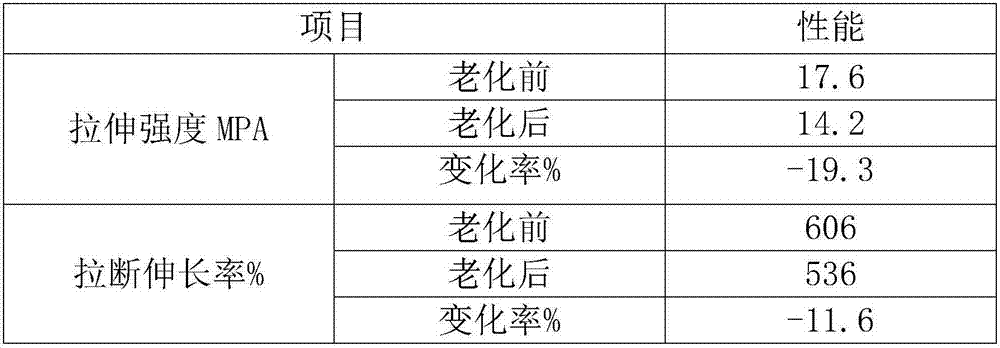

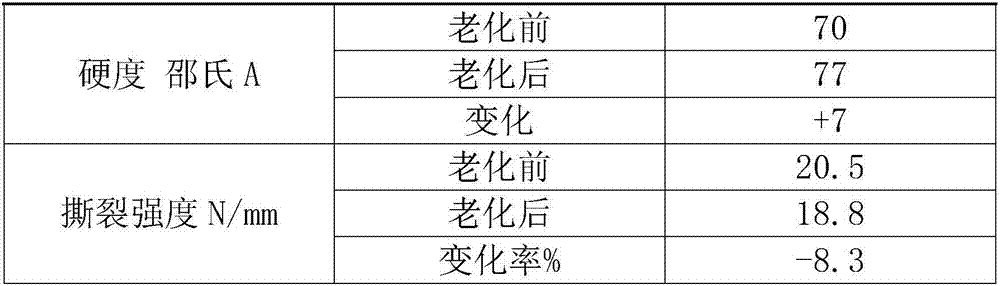

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described below in conjunction with examples, which only further explain the present invention, but do not limit the present invention.

[0021] The example of the present invention provides a high temperature resistant conveyor belt cover rubber, the formula includes the following mass components: thermoplastic elastomer containing ethylene segment: 100 parts, carbon black filling reinforcing agent: 50 parts, plasticizer: 15-30 parts parts, active agent: 5-10 parts, stearic acid: 1-2 parts, anti-aging agent: 3-5 parts, heat-resistant additive: 10-20 parts, peroxide cross-linking agent: 3-5 parts, cross-linking agent: 3-5 parts, Joint auxiliary agent: 0.5-3 parts.

[0022] The thermoplastic elastomer composite material, because the thermoplastic elastomer has a certain degree of crystallinity, the thermoplastic elastomer is mixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com