Magnetic shape memory alloy and preparation method thereof

A memory alloy and magnetic technology, applied in the field of magnetic shape memory alloy and its preparation, can solve the problems of low Curie temperature, high brittleness, and high threshold value of magnetic field-driven phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 45.4 parts of Ni, 41.5 parts of Mn, 11.1 parts of In and 2 parts of Gd according to atomic percentages and put them into the vacuum non-consumable electrode electric arc furnace. The order of placement from top to bottom is Ni, In, Gd, Mn; arc melting for 20 minutes under the protection of argon and 100A melting current, suck and cast into a rod-shaped sample of Φ10mm×75mm in the device at the bottom of the water-cooled copper crucible, and then mechanically polish the alloy rod body with acetone. Then put the vacuum to 10 -2 In the Pa quartz tube, keep it at 900℃ for 12h, and then quench it into water; that is to obtain high temperature and high plasticity Ni 45.4 Mn 41.5 In 11.1 Gd 2 Magnetic shape memory alloy.

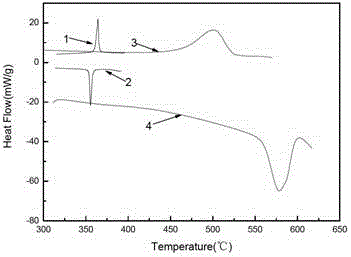

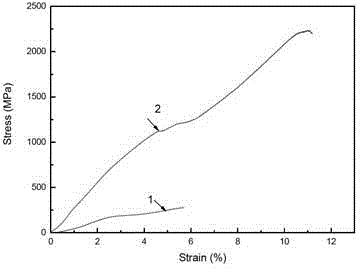

[0022] The high temperature and high plasticity Ni prepared in this embodiment 45.4 Mn 41.5 In 11.1 Gd 2 Alloy and Ni 45.4 Mn 41.4 In 13.1 Gd 0.1 The heating DSC curve of the alloy was measured under the condition of a heating rate of 10K / min, and the cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com