Solar dryer hood device of high-speed reverse-net multi-roll drying special paper-making machine

A drying cylinder cover and solar energy technology, which is applied in the field of manufacturing tissue paper machines, can solve the problems of large carbon monoxide and carbon dioxide emissions, affecting ink printing effect and transfer effect, and low production efficiency, so as to improve gloss and tightness Improvement, effect of physical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is an example of using a right-hand mobile phone, and does not limit the implementation scope of the present invention. All equivalent changes or modifications made according to the structure, features and principles described in the scope of the patent application of the present invention should be included in the scope of the patent application of the present invention .

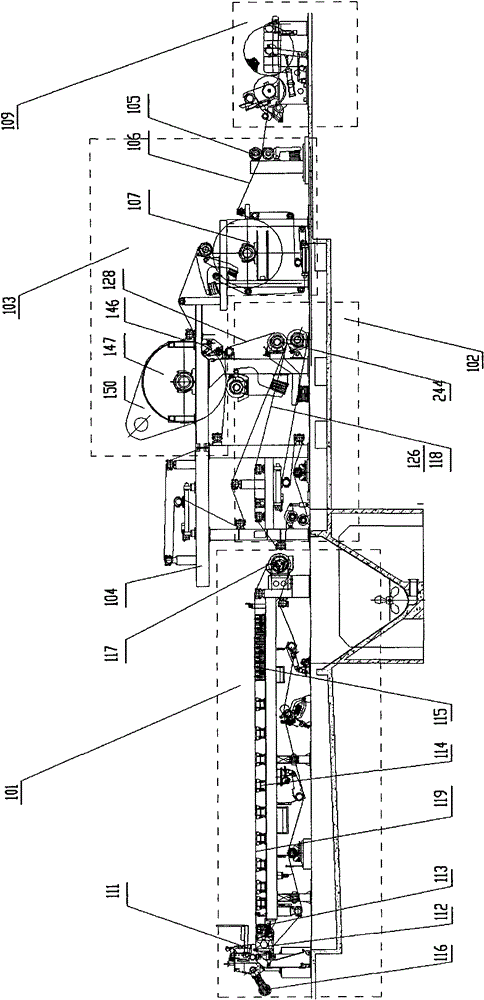

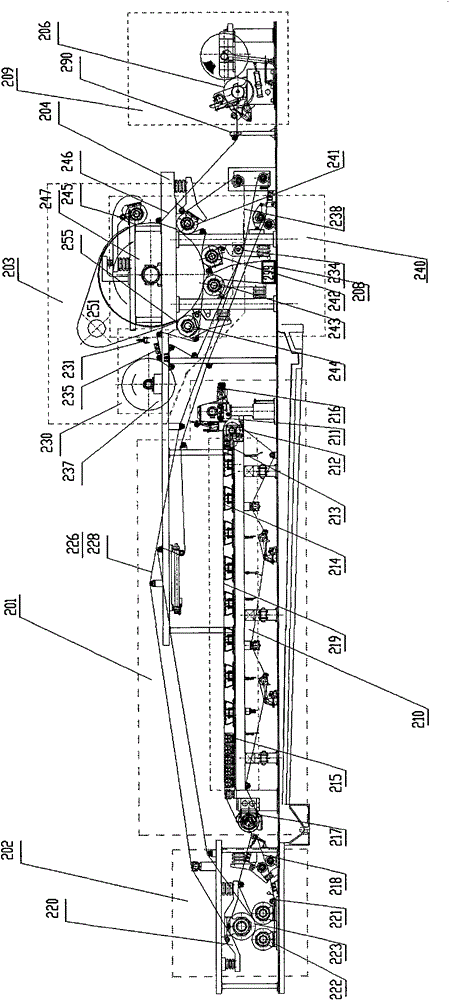

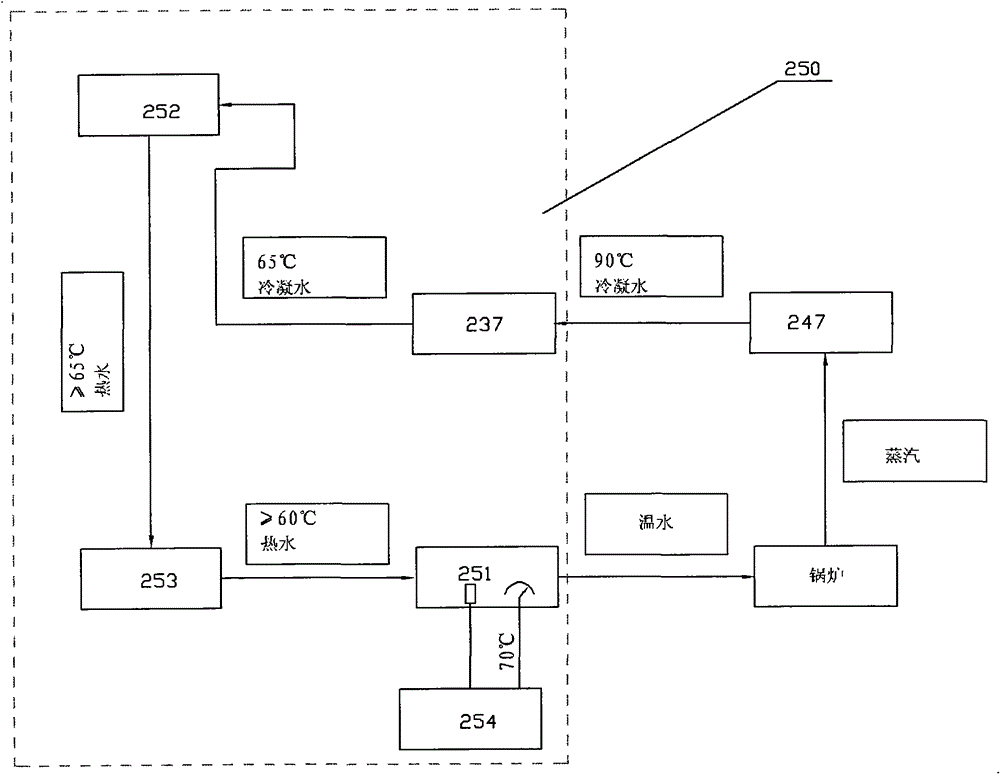

[0050] Such as Figure II Shown: a high-speed reverse wire multi-roll drying special paper machine for manufacturing transfer printing base paper and decorative base paper and other tissue papers. The pressing device 220 in the press area, the semi-wet felt device 230, the multi-roll drying device 240, the solar dryer cover device 250, and the printing performance adapting agent application device 208 are composed. The running direction of the reverse forming screen device 210 is opposite to that of the complete machine. The reverse forming screen device 210 is characterized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com