Color-temperature-adjustable high-color-rendering light source module

A light source module, high color rendering technology, applied in the field of LED packaging, can solve the problems of color temperature shift, complex driving circuit, inconsistent aging and attenuation of various chips, etc., to improve color mixing, improve light output power, simple, efficient and low-efficiency The effect of cost scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

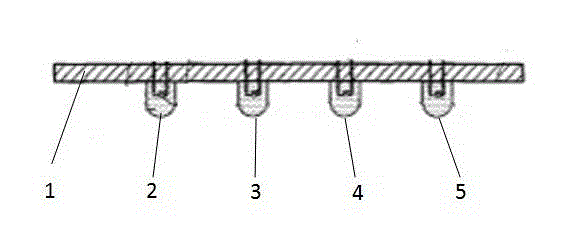

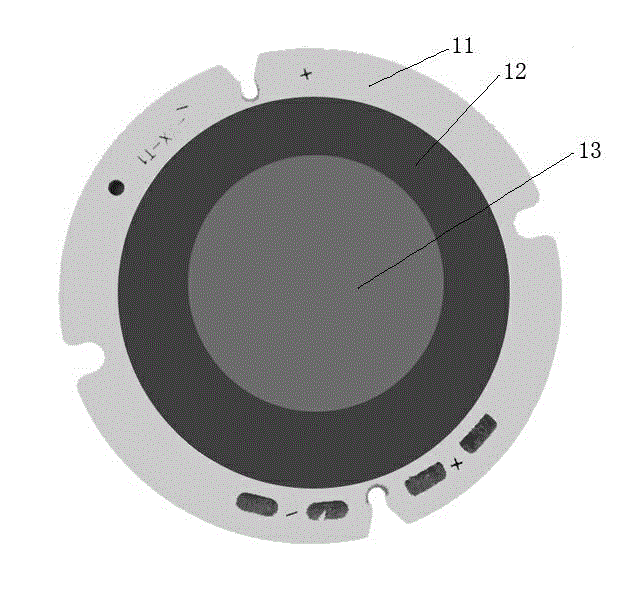

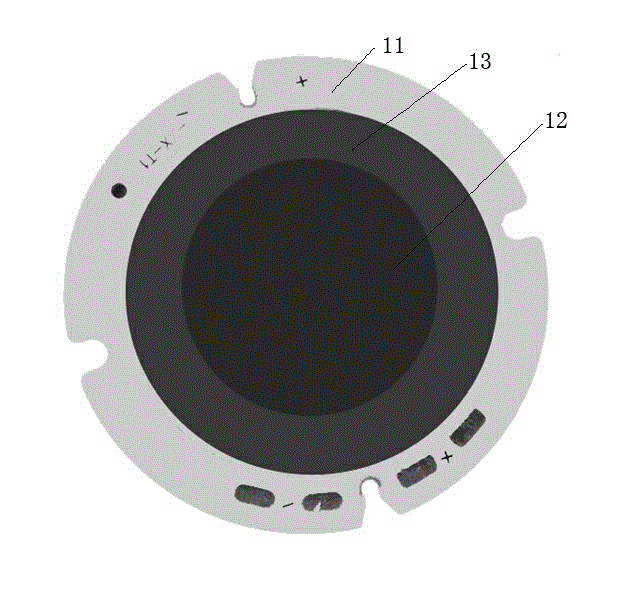

[0023] refer to Figure 2-3 As shown, a high color rendering light source module with adjustable color temperature according to the present invention includes a substrate 11 and an LED chip, the substrate is provided with a die-bonding area and a common circuit, and the LED chip is fixed on a solid-state On the crystal area and connected to the public circuit, the crystal-bonding area is divided into at least two integrated areas, and the integrated area is composed of various figures formed by the end-to-end connection and closure of circles and / or line segments. The public circuit is an integrated metal plate and is arranged corresponding to the integrated area. The shape of the metal plate forming the public circuit is preferably the same as the corresponding integrated die-bonding area. The adjacent two public circuits are insulated from each other and the electrodes On the contrary; the crystal-fixing area is provided with a phosphor layer, and the phosphor layer is divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com