Nozzle for enhancing atomization by plasma

A technology of atomizing nozzles and plasma, which is applied in the direction of combustion methods, burners, combustion chambers, etc., to achieve the effects of increasing flame propagation speed, easy combustion, and ensuring stability and completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

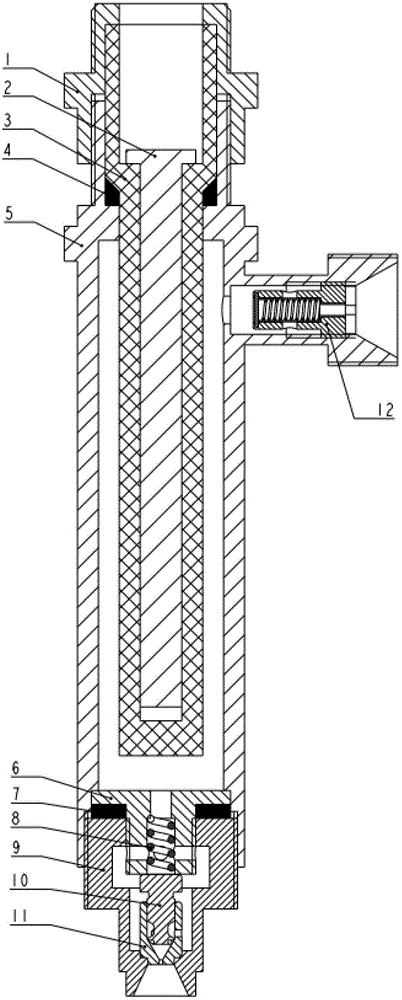

[0016] combine figure 1 , the present invention mainly includes a low-temperature plasma discharge assembly, an oil filter assembly 12, a swirler assembly, and a fuel atomizing nozzle. The low-temperature plasma discharge assembly mainly includes: an outer electrode 5, a ceramic barrier medium 3, an inner electrode 2, a power connection frame 1, and a graphite sealing ring. The ceramic barrier medium 3 is designed in a top-closed mode, and the graphite sealing ring 4 is used to achieve sealing with the outer electrode 5, and the inner electrode 2 is in it, which can effectively avoid arc discharge at the end and ensure the discharge uniformity and stability of the discharge area; ceramics are used as the barrier The medium can effectively prevent discharge breakdown and improve the service life of the plasma-enhanced atomizing nozzle. A discharge area is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com