System and method for laser flatness measurement

A flatness and plane technology, applied in the field of laser plane measurement system, can solve the problems of low efficiency and slow detection speed, and achieve the effect of convenient replacement of workpieces, improvement of efficiency, and convenient product positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

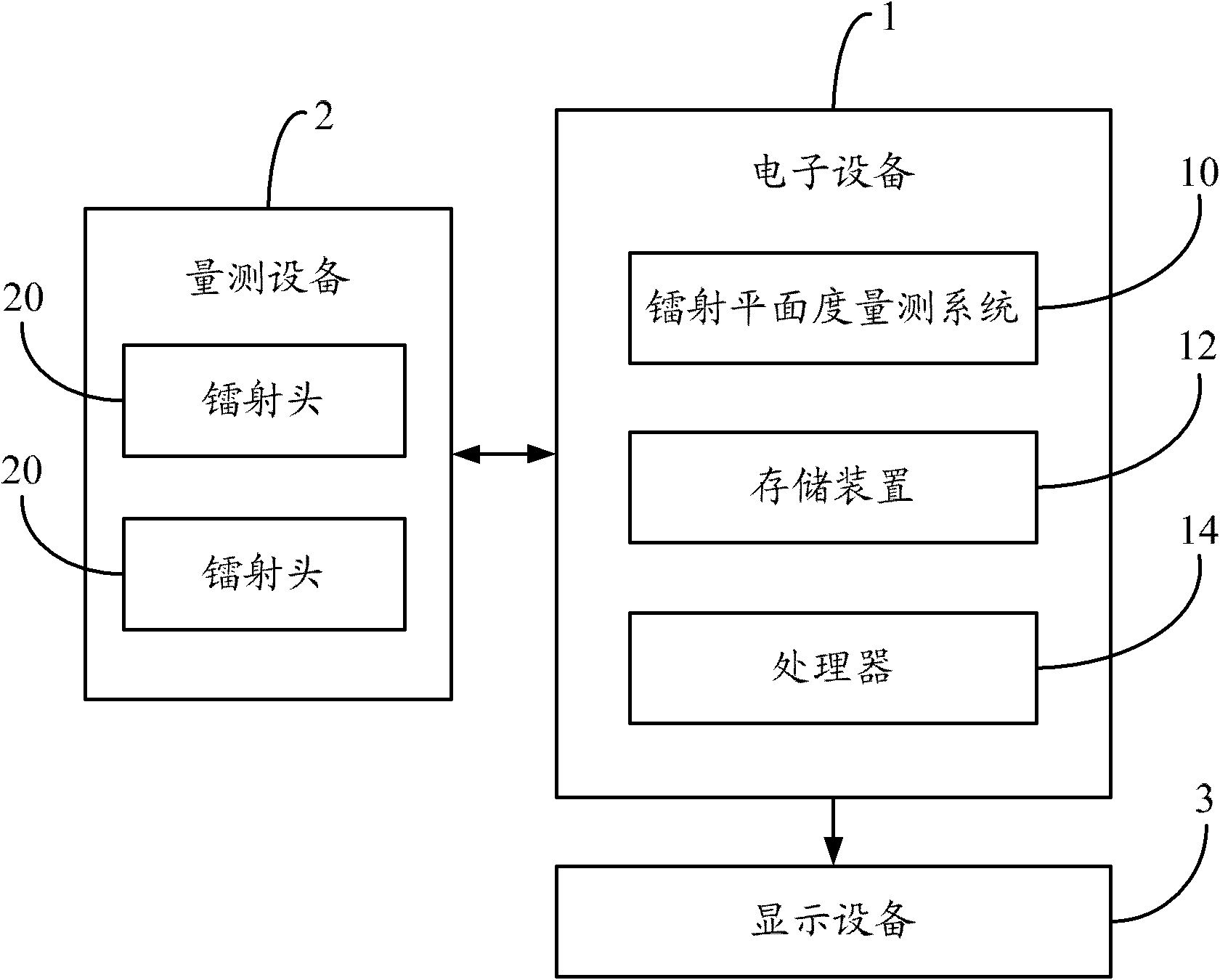

[0016] refer to figure 1 As shown, it is a schematic diagram of the operating environment of the preferred embodiment of the laser plane metrology system of the present invention. The laser plane measuring system 10 runs in an electronic device 1 (such as a computer), and the electronic device 1 is connected with a measuring device 2, and the measuring device 2 has two laser heads 20 and a workbench , the user can clamp the jig with the workpiece on the workbench before the laser head 20 measures the workpiece. In this embodiment, two workpieces can be installed on the jig at the same time, and the two laser heads 20 are respectively located above the two workpieces for scanning the two workpieces to measure the two workpieces. For example, the laser head 20 includes a and b, and the two workpieces installed on the fixture are c and d respectively, wherein, a is located above c, b is located above d, a is used to scan c, and b is used to scan d .

[0017] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com